Iron and carbon are both found in the alloy known as steel. It can be used in a wide range of contexts, including the building of homes, bridges, and skyscrapers. With a 1.6 billion tonne annual capacity for steel manufacturing, demand for this precious resource is consistently high. Utilizing basic materials including iron ore, coal, and limestone, steel manufacturing facilities create steel ingots. About 80% of the world’s needs for iron ore are met by coal, leaving the remaining 20%.

Visit this Page for more Information: Start a Business in Steel Industry

Uses and Applications:

One of the most frequently utilised metals worldwide is steel. It offers a good strength-to-weight ratio and strong durability. It is practical for a variety of applications thanks to this combination. While steel is easily accessible on the open market, there are specific situations when using scrap steel may be more cost-effective. For instance, purchasing steel scrap rather than a complete ingot at once may be a better choice if you need to produce something tiny or rapidly. Create a boiler, treadmill, or forge using steel ingots. As a result, maintaining a consistent supply of steel is essential to meeting demand.

Related Business Plan: Setup Steel Ingot from Scrap Business

Manufacturing Process:

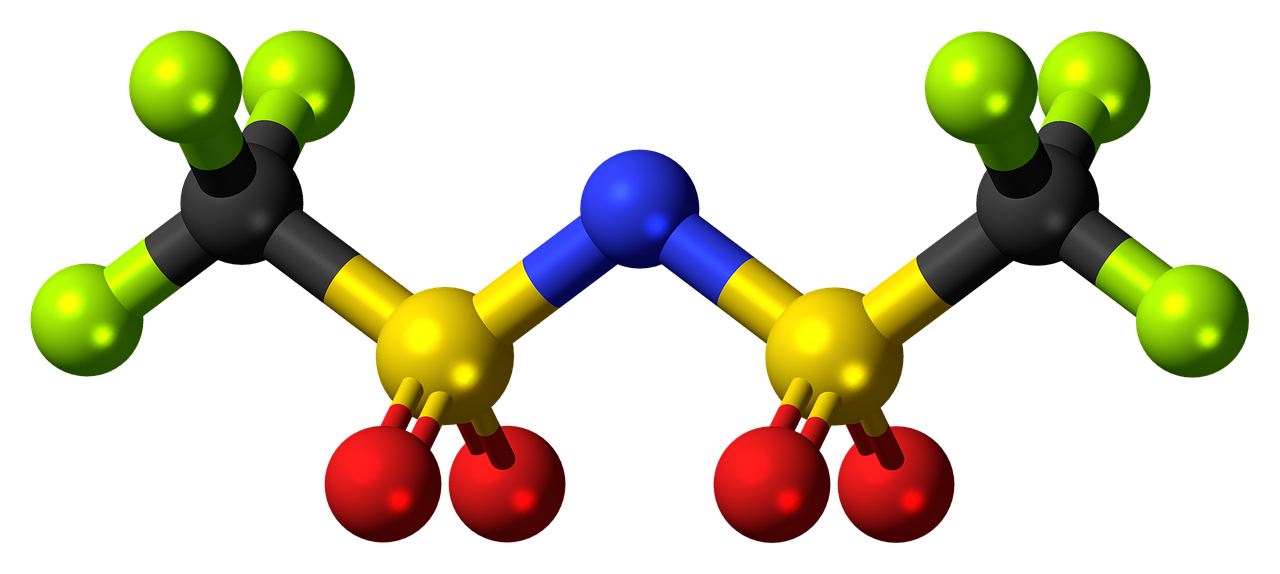

Iron and carbon are two of the metal alloys that make up steel, along with a few other components. It is the most widely used metal due to its ease of shaping and forging, strength, durability, and affordability. Smelting, or heating iron ore in an electric furnace to create liquid steel, is the first step in the production of steel.

Casting is the process of further processing liquid steel into various sorts of steel products like bars or ingots once it has cooled. Up to 12% nickel and 2% to 20% chromium make up the alloy known as steel. Other metals like silicon, manganese, and others typically make up the alloy’s remaining parts. Carbon steel, stainless steel, and tool steel are the three primary categories of steel.

Read Similar Articles: STEEL INGOT FROM SCRAP

Benefits of Starting Steel Ingot from Scrap Business:

Although steel is a necessity for daily living, the steel industry is also among the most wasteful. For this reason, you might wish to think about launching a steel ingot firm that turns scrap steel into fresh goods. The following are some advantages of starting this kind of business: You are free to set your own work schedule and hours. – Offers variety and customisation options – Is simpler to launch than other enterprises – Is a more recent method of recycling steel In many locations, scrap steel is easily accessible and is far more affordable than new metal. Due to the fact that only labour is required to create the ingots, rather than spending as much on resources, the cost of production will also be reduced.

Read our Books Here: The Complete Technology Book on Steel and Steel Products (Fasteners, Seamless Tubes, Casting, Rolling of Flat Products & others)

Market size in India:

Metal consumption has been one of the main driving causes behind industrialization. Steel has long held the top position among metals. Steel is both a raw material and an intermediary product, therefore its production and consumption are commonly used as indicators of a nation’s economic success. Therefore, it would not be overstating the case to say that the steel industry is the backbone of any economy and has always been at the forefront of industrial advancement.

Download Pdf: A Global Recycling Business, Setup Steel Ingot from Scrap to Reduce Landfill and Save the Environment

The steel industry in India is divided into three groups: primary producers, secondary producers, and large producers. With an output of 10.14 MT as of April 2022, India was the second-largest producer of crude steel worldwide. The output of unfinished steel in FY22 and finished steel, respectively, were 133.596 MT and 120.01 MT. The domestic accessibility of raw materials like iron ore and the affordability of labour have been the main drivers of growth in the Indian steel industry. As a result, the steel industry has been crucial to India’s manufacturing output. Modern steel mills are present in the Indian steel sector. It has always worked to upgrade older plants to better energy efficiency levels and to continuously modernise them.

Related Feasibility Study Reports: Set Up Steel Ingot From Scrap Plant

Global Market Outlook:

The market for Setup Steel Ingot from Scrap is expanding globally. There are only a few notable businesses in the established steel ingot from scrap business field. These companies are a leader in the setup of steel ingot from scrap business due to their state-of-the-art technology, competence, and in-depth understanding. The market for steel scrap is anticipated to increase from its estimated size of 574.1 million metric tonnes in 2020 to a total of 784.8 million metric tonnes in 2027, with a projected Compound Annual Growth Rate of 4.6% between 2020 and 2027.

Click here to send your queries/Contact Us

See More Links:

- Start a Business in Asia

- Start a Business in Potential Countries for Doing Business

- Best Industry for Doing Business

- Business Ideas with Low, Medium & High Investment

- Looking for Most Demandable Business Ideas for Startups

- Startup Consulting Services

- Start a Business in Africa

- Start a Business in India

- Start a Business in Middle East

- Related Videos

- Related Books

- Related Projects

- Related Market Research Reports