The manufacturing and industrial sector has been at the center of economic growth and innovation for decades. Today, as synchronously technology changes and the global marketplace changes, opportunities for entrepreneurs and startup capital integration are reappearing. Understanding the current context, market context and expectations for the future is critical for anyone thinking about entering or growing a manufacturing business.

Transforming Landscape in Manufacturing

The manufacturing sector is going through an innovative resurgence – driven by digital transformation to sustainability agenda and sustainable supply chains are resurging. Automation, robotics, and Industry 4.0 technology are evolving the capabilities of the manufacturing sector by decreasing costs and increasing efficiency.

High-Growth Sectors and Areas of Market Demand

Renewable Energy Equipment

Solar panels, wind turbines, and battery storage are in high demand as the world shifts to cleaner energy sources. This transition is driving strong investment opportunities for manufacturing businesses, in the renewable supply chain sphere.

Food and Beverage Processing

Detailed project report on investment opportunities

Medicines and Medical Devices

The worldwide focus on healthcare is creating growth in the life sciences in generic drug manufacture, medical device assembly, and diagnostic kit production – sectors characterized by significant and recession-proof demand.

Components of Electric Vehicles

The automotive industry is being transformed rapidly by the emergence of electric vehicles. This has spurred more investment in the manufacture of batteries, electronic parts, and ultra–light materials.

Consumer Electronics

Industry Outlook and Trends

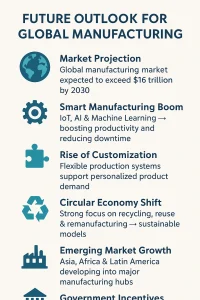

The outlook for manufacturing is overall positive in the long term. The global manufacturing market is projected to exceed $16 trillion by 2030 and steadily grow further with a solid compound annual growth rate. Smart manufacturing, fueled by the remarkable changes taking place through IoT, artificial intelligence, and machine learning continues to propel productivity and downtime even lower. In addition, the growing demands on the produce side is pushing manufacturers to adopt production systems that are flexible to supply to the consumer need for customized and personalized products.

Potentials for Profitable Investment

For more information, here is our Handbook

Manufacturing Process: From Idea to Implementation

Market Research and Feasibility Analysis

A smooth and successful manufacturing venture begins with proper due diligence in the form of internal or external market research, in which market demand trends are monitored and assessed, as well as competitive market landscape, and regulatory landscape assessments, to ensure the feasibility and sustainability of the company.

Design and Prototype Development

Entrepreneurs then create product ideas, develop prototypes, and iteratively improve designs for efficient sourcing, favorable manufacturing economics, and customer specification.

Sourcing Raw Materials

Reliable suppliers must be selected and established, and quality control procedures need to be put in place to ensure quality consistency and product conformity.

Facility Preparation and Plant Layout

Correctly selecting the location, developing the most efficient plant layout, and selecting the right machinery must be established prior to manufacturing.

Production and Quality Assurance

Once the new manufacturing company becomes operational, to develop and maintain manufacturing consistency, safety, and continuous improvement, there needs to be standard operation procedures and good quality assurance methodologies for all manufacturing processes.

Packaging and Distribution

Important Factors for Entrepreneurs

In today‘s manufacturing world, the use of technology is a differentiator. The use of processes, automation, data analytics, and digital tools has the potential to dramatically increase productivity and competitiveness. Accordingly, entrepreneurs must consider placing technology adoption high on priority lists.

Talent pools are equally important due to the design and operation of advanced machinery and processes. Sustainability in manufacturing must be top of mind to not only comply with regulatory obligations but also attract environmentally conscious customers.

Related articles:- Investment Opportunities in Solvent Recycling and Repacking Businesses

Expert Guidance from Niir Project Consultancy Services (NPCS)

Expert guidance can make a significant difference when launching a new manufacturing or industrial venture. Niir Project Consultancy Services (NPCS) is a trusted partner for entrepreneurs, offering Market Survey cum Detailed Techno Economic Feasibility Reports.

These comprehensive reports cover every aspect of a project, including the manufacturing process, raw materials, plant layout, and financials. NPCS helps entrepreneurs assess the feasibility of setting up new industries or businesses, providing valuable insights and actionable recommendations that can pave the way for success.

Conclusion

The manufacturing and industrial sector is ripe with investment opportunities for those willing to innovate and adapt. By staying informed about market trends, leveraging the latest technologies, and following a structured approach to business setup, entrepreneurs can position themselves for long-term growth and profitability.

Whether your interests lie in renewable energy, food processing, healthcare, or advanced materials, now is an opportune time to invest in manufacturing. With the right research, strategic planning, and expert support, your venture can thrive in this ever-evolving industry.

If you’re ready to explore your next big manufacturing venture, start with thorough research, strategic planning, and the right partners to guide your journey. The future of manufacturing is bright, and with determination and the right resources, you can turn your vision into a successful reality.

Find best business ideas for yourself using our startup selector tools

Frequently Asked Questions

What are the most promising manufacturing sectors for new investment?

Currently, sectors such as renewable energy equipment (solar panels, wind turbines, batteries), food and beverage processing, pharmaceuticals and medical devices, automotive components (especially for electric vehicles), and consumer electronics are showing strong growth and high demand. These areas are driven by global trends like sustainability, technological innovation, and changing consumer preferences.

How important is technology adoption in modern manufacturing?

Technology adoption is crucial for competitiveness in today’s manufacturing landscape. Automation, robotics, data analytics, and digital tools can significantly improve productivity, reduce costs, and enhance product quality. Embracing Industry 4.0 technologies also enables manufacturers to respond quickly to market changes and customer needs.

What steps are involved in setting up a manufacturing business?

The process typically starts with thorough market research and a feasibility study, followed by product design and development. Entrepreneurs then source raw materials, set up the manufacturing facility, implement production and quality control systems, and finally, develop packaging and distribution strategies. Each step is essential for building a sustainable and efficient operation.

How can startups ensure sustainability in manufacturing?

Startups can focus on energy-efficient processes, waste reduction, and the use of eco-friendly materials. Implementing sustainable practices not only meets regulatory requirements but also appeals to environmentally conscious consumers and can provide a competitive edge in the market.

What are the main risks in the manufacturing sector, and how can they be managed?

Key risks include supply chain disruptions, regulatory changes, market volatility, and technological obsolescence. Effective risk management involves diversifying suppliers, staying updated on regulations, investing in flexible production systems, and continuously monitoring market trends.