Rubber is a silent enabler for modern life. Most people don’t think about rubber, but we use it all the time. Doctors use rubber gloves when they do surgery. Even a simple rubber band that holds things together uses rubber. Rubber is everywhere. It helps us in many ways, even if we don’t notice it. It’s very important for people all over the world. The rubber processing business is the key intermediary of this value chain. It transforms the milky latex that comes from trees into an enduring, durable and commercially viable material.

This is an important business, especially in the rubber-growing areas. Entrepreneurs have a great opportunity to get involved in an industrial primary activity that has a consistent demand, and also offers value-adding potential. This article is a comprehensive guide on the rubber processing industry. It explores the intricacies, the business models that are viable, how to set up a unit and the future trends of this dynamic industry.

Understanding Rubber as a Raw Material

Rubber is classified into two main categories: Rubber can be divided into two broad categories:

Natural rubber (NR)

Natural rubber is made from isoprene polymer. It is harvested as a liquid milky substance called latex.

- Latex concentrate: A liquid of high concentration used to dip goods such as gloves, balloons and condoms.

- Dry rubber forms: These are the solid forms of rubber, such as tires and tires.

Synthetic rubber (SR)

Synthetic rubber, also known as elastomers, is a synthetic elastomer that is derived from petroleum products. It has different types of elastomers, including Styrene Butadiene Rubber, Nitrile Rubber, and Neoprene. Each type is engineered to have specific properties, like resistance against heat, oil, or chemicals. This article, while important to the rubber industry as a whole, will concentrate on the processing natural Rubber. This is the most accessible way for entrepreneurs to start a business in the rubber processing sector.

Read More: Start Manufacturing Business of Styrene Butadiene Rubber (SBR)

The Rubber Processing Chain

Rubber processing businesses are located in the middle of the value chain. They convert perishable rubber into stable industrial raw materials.

- Bulking and Collection: The collection process begins with the collection and bulking of latex.

- Coagulation and Dilution: After dilution, a coagulant is added. This is usually formic acid or acetic acid. After this, the coagulant is added, usually acetic or formic acid.

- Rolling and Sheeting: A slab of coagulum will be passed through a set of rollers. The first rollers are smooth, and their primary function is to squeeze excess water. The final roller is a grooved roller or ribbed one. It imprints ribbed patterns onto the sheets. This pattern increases surface area which helps in the drying process.

- Smoking and Drying: Wet sheets with ribs are taken to the smokehouse where they are hung up on racks and dried by heat and smoke produced by a controlled fire. This process is a multi-day procedure that serves two purposes.

- Drying : Heat removes moisture.

- Smoking The smoke is a mixture of chemicals (phenols), which prevent mold and bacteria from growing, preserving rubber. The sheets also get their characteristic amber-brown color from the smoke.

- Grading & Baling: After the sheets dry, workers look at them to check for mistakes. They use some rules called the “Green Book.” They check the color, how clear the sheets are, and if there are bubbles or dirt in them. Good sheets get pressed into big bales. Workers mark the bales, wrap them up, and get them ready to ship to the next place.

The Complete Book on Rubber Processing and Compounding Technology

Profitable rubber processing business models

There are several ways that entrepreneurs can enter the rubber sector.

Ribbed Smoked Sheet Production Unit

This is the traditional and most common business model. RSS is the raw material of choice for the Tire Industry which consumes more than 70% of all natural rubber in the world. The process of setting up an RSS unit is relatively simple and requires only a moderate amount of capital. The product is easy to trade because it has a market that’s well established and standard grading systems.

Production of Latex Concentrate

This venture is more technically intensive. The dry rubber content (DRC) is increased from 30% to 60% by using centrifuges. The primary raw material used by industries to manufacture dipped products such as medical gloves, condoms and balloons is latex concentrate. This model is more expensive to implement but it caters to high-value markets.

Read More: Rubber Manufacturing Business-Why to invest in this Business?

Crumb rubber Manufacturing

This business takes old, leftover rubber—like scraps and tree lace. They wash it, cut it up, crush it, and dry it. After all that work, they get something called crumb rubber. Some people call it TSR, but honestly, it’s just cleaned-up rubber bits. It is becoming more popular because of its consistency in quality and ease of use. This model is vital for reducing waste, and adding value to low-grade materials.

Toll Processing Service

Toll processing is a great option for entrepreneurs who want to reduce raw material risks. This setup involves the establishment of a processing unit by the business and offering its services to small plantation owners who do not have their own processing facilities. The unit charges farmers a fee to convert their latex into sheets or blocks. This approach ensures a steady income from operations without being affected by the fluctuations in raw rubber prices.

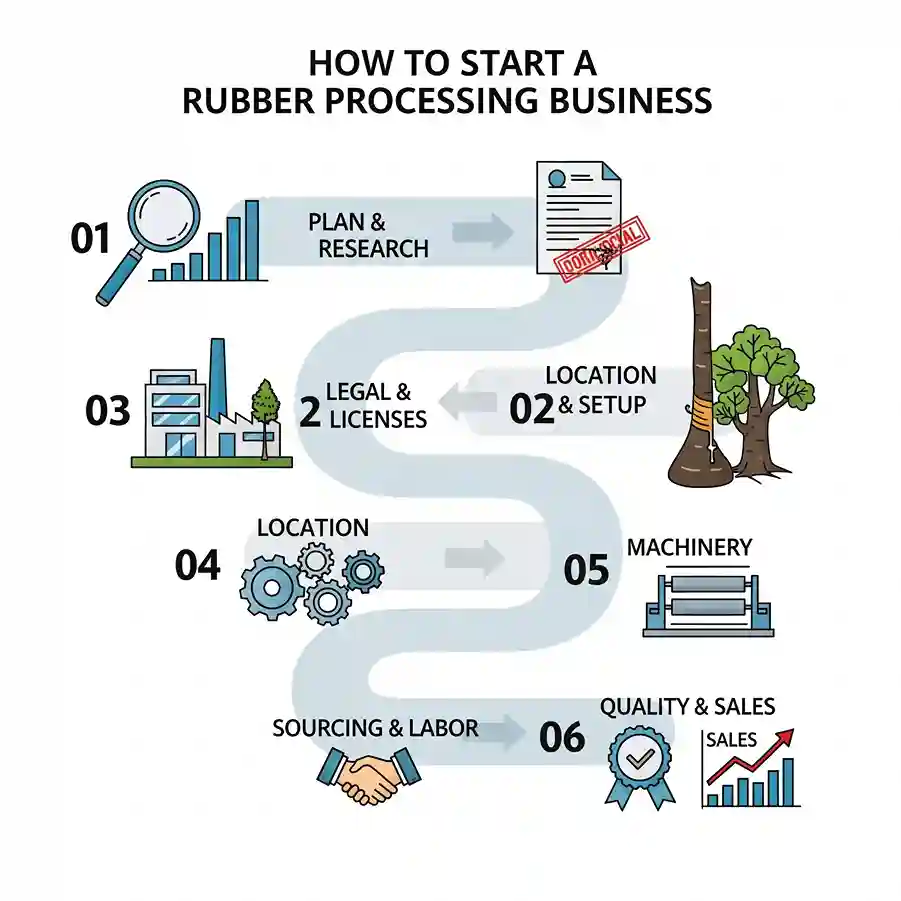

A Guide to Starting a Rubber Processing Business

The launch of a rubber-processing unit requires careful planning and execution.

Step 1. In-depth market research and business plan

Your first step should be to do a thorough study of the demand in your area for various types of rubber processed. Determine your target buyers, such as tire manufacturers, latex producers, and footwear companies. Create a comprehensive Business Plan that details your production capacity, market, financial projections, (startup expenses, operational costs, revenue forecast), marketing strategy, and more.

Read More: Crumb Rubber Powder Business: A Green & Profitable Opportunity

Step 2: Legal Formalities

Register as a business entity (e.g. a sole proprietorship or partnership). Get the necessary registrations such as GST, Udyam Aadhaar and a business license. In India, you will need to obtain a rubber board license Rubber Board of India before you can operate as a rubber processor or dealer.

Step 3: Infrastructure and Location Setup

Your unit’s location is crucial. It should be located close to rubber plantations in order to minimize transportation costs and ensure a constant supply of fresh, latex. Basic infrastructure includes:

- The area covered for the latex tanks and coagulation tanks

- The sheeting machines are housed in a processing shed

- The smokehouse should be designed with adequate ventilation and fire safety measures

- Secure warehouse to store finished bales

- A system for treating the acidic whey that is discharged following coagulation

Read Our Project Report: Rubber and Rubber Products, Rubber based Industries…

Step 4 – Purchasing Machinery and Equipment

Based upon your chosen business model you will need to purchase the required machinery. This would include the following for an RSS unit:

- Sieves, collection tanks and other equipment

- Coagulation tanks are available in aluminum or cement

- The sheeting machine/roller set (manual or powered)

- The baling press can be either hydraulic or screw type

- Weighing scales

Step 5: Purchasing Raw Materials and Labor

Create a network of rubber tappers in your area and plantation owners. To ensure a reliable and consistent supply of latex, offer fair prices and prompt payments. Hire skilled labor to operate the machinery, grade the sheets and semi-skilled workers for collection and handling.

Step 6. Quality Control, Marketing and Sales

The quality is paramount. Stick to the established standards for grading. Hire a grader who is experienced to ensure that your product gets the right market price. Market your rubber products to downstream industries. To secure sales, build strong relationships with large and consistent buyers.

Discover the Right Business for You With Our Startup Selector Tool

Conclusion

Rubber processing is a strong business that provides a link between agriculture, industry and commerce. It is a robust venture that offers enormous potential for growth and profitability. A resilient business can be built by choosing the right model, focusing operational efficiency and building a solid supply chain. This will not only help the local rubber farmers, but also contribute to the manufacturing eco-system. Rubber’s enduring demand will ensure that the industry continues to be a story of transformation and growth.

Rubber Processing Business: FAQs

Q1. How much money do you need to start a small rubber processing unit?

You need some money, but it’s not out of reach. For a small RSS rubber processing setup that makes about 500 to 1000 kg every day, you’ll need around ₹15 to ₹30 lakhs (about $20,000–$40,000). This money will pay for machines, a building, and starting costs.

Q2. Who buys most of the processed natural rubber in India?

Most of it goes to the car industry, especially tire makers. They use more than 70% of the rubber. Other buyers are shoe companies, people who make belts and hoses, and makers of things like medical gloves.

Q3. What are the grades of Ribbed Smoked Sheets (RSS)?

RSS rubber has different grades. The best is RSS1X, then RSS1, RSS2, RSS3, RSS4, and RSS5. People check color, dryness, and if there’s any dirt or bubbles to decide the grade. RSS1 is top quality, but RSS3 and RSS4 are the ones tire companies use most.

Q4. Do you need a license from the Rubber Board of India?

Yes, you do. If you want to work with rubber—processing, making stuff, or selling—you have to get a license from the Rubber Board. It’s the law.

Q5. How can processors handle price changes?

There are a few ways. You can make deals with buyers for fixed prices, so you don’t worry about sudden changes. Try to keep your costs low and manage your stock well. Big companies sometimes use the market to protect against price changes. These steps help you avoid big losses.