Biodegradable polymers can be used to substitute traditional plastics which are made of petroleum and may require hundreds of years to dissolve. With the maize plant, you can design biodegradable plastic which contains 100 percent of natural materials that can decompose within a few months. It will be a win-win situation since this new type of plastic is not only environmentally friendly, but it is also cheaper than the traditional plastics.

It will not require many additional costs to make this new biodegradable plastic, but after retailers begin to buy this new type of plastic and replace the old packaging with it, hopefully, it will be different within the next two years!

Also, the material is environmentally non-polluted since it is purely natural. You no longer have to worry about the fact that you have a carbon footprint since there is an excellent alternative that you can go green at this point and not destroy the environment.

More Information can be found on this Page: Start a Business in the Biodegradable Products Industry.

Uses and Applications:

The utilization of corn to manufacture is innovative and can be utilized to produce packaging and other items. Such polymer is created without any fossil decrees or discharge of greenhouse gases since it is manufactured using renewable resources. Moreover, it is biodegradable, and it means that after one year it will break up and it will not leave any poisonous trace.

Already the business has created material samples applicable in daily products such as water bottles, supermarket bags among other products.

The possible contribution of bioplastics made out of plants in our society is massive. Imagine the number of single-use plastic bags you would not use to take your purchases home and consider it the benefit to the society and environment! However, manufacturers do not intend to substitute the conventional plastics such as polypropylene (PP) or polyethylene terephthalate (PET) with such materials, but rather complement them; that is why they give each biodegradable plastic its own special properties and uses less energy to make them.

Further Business Plan: Bio-Degradable Corn Plastic Polymer.

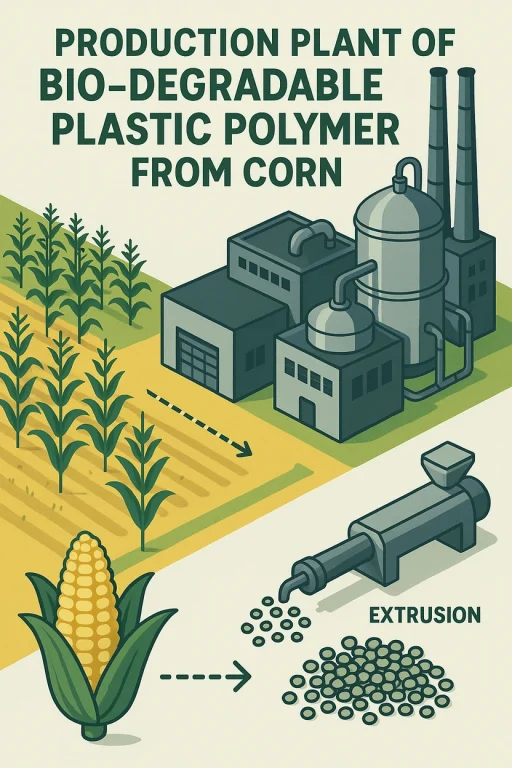

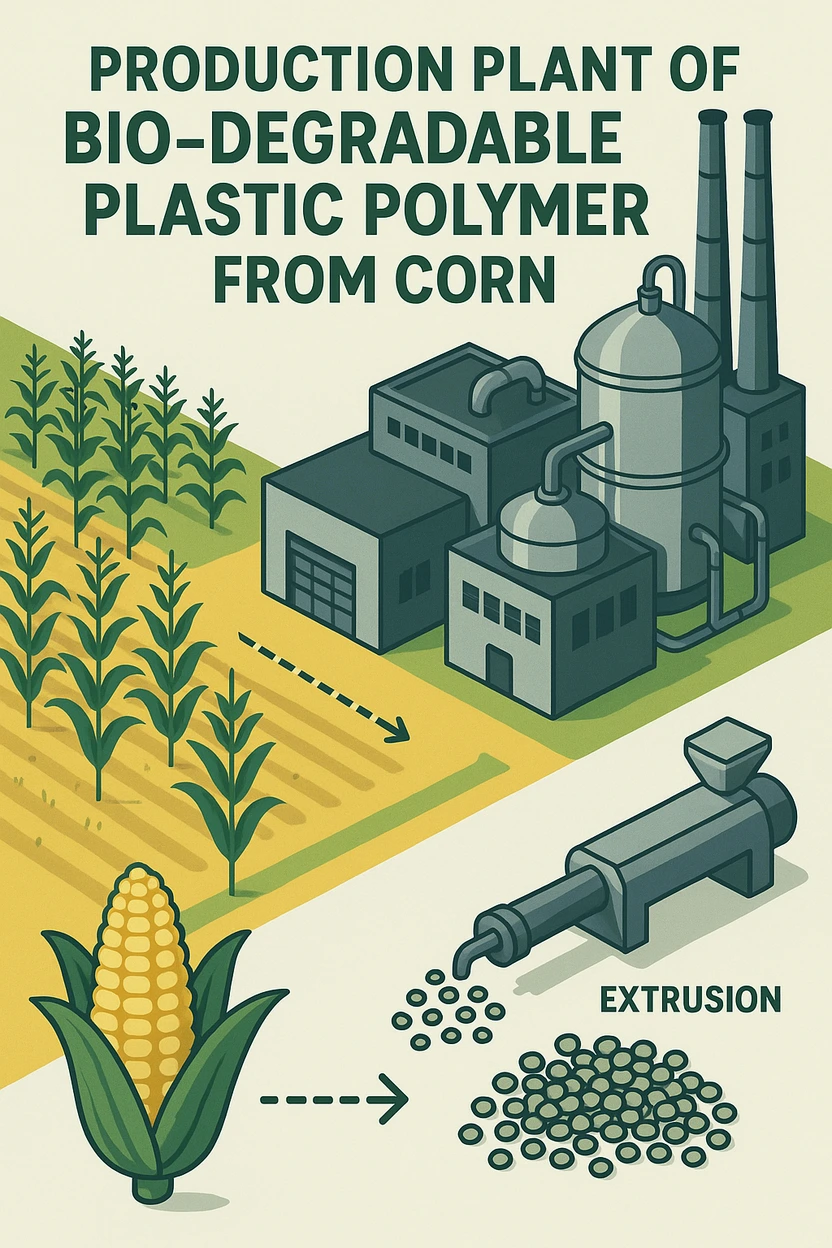

Manufacturing Process:

Corn has to be produced as a raw product. Put in a catalyst and prepare the degradable polymers as homogenous as possible. Second, high pressure should be applied to it prior to loading it in the reactor. The starting point is PMR which is a biodegradable plastic. Third, after preparing the base polymer, a binder, color and other required additives are added carefully to convert the base polymer into the final products of biodegradable films, bags and bottles. Lastly, the products need to be packaged in a way that can be sold to the market to make the process complete.

Advantages of the Starting Bio-Degradable Plastic Polymer based on Corn Production Business:

Less expensive than polythene. Disposable resources as well as biodegradable ones are renewable and reduce our dependence on fossil fuels (particularly oil). The energy saved will be of great help to our society, economy and our environment.

It minimizes landfilling, which is a significant environmental problem in the world.

It has more environmental advantages compared to most other materials.

It provides slow-release nitrogen, thereby improving the quality of the soil and making the soil fertile.

The compressive power is high and enables the manufacturer to produce toys, containers, utensils among others.

Market Size in India:

The growth of consumer-friendly products, eco-friendly, mandatory and regulatory, corporate sustainability, technology stabilization, and cost reduction are some of the drivers of the Indian bio-plastics market.

The major contributors to this proliferation (polyethylene terephthalate) are the non-biodegradable polymers such as PET and PE manufactured using bio-based materials. Some of the biodegradable polymers like polyhydroxyalkanoates, polylastic acid, and polylactide (PLA) are slowly gaining business revenues.

Polyethylene and polyethylene terephthalate are materials that are increasingly being employed in the packaging industry hence the growth in demand of non-biodegradable plastic. Nevertheless, even with the increasing environmental issue, the scarcity of substitute products and the unawareness of the consumer contribute to the further development of the market of biodegradable plastics greatly.

Connected Feasibility project Reports: How to Make a Successful Business Out Of Bio-degradable Plastic Polymer Made of Corn.

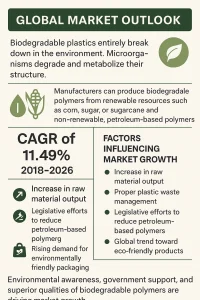

Global Market Outlook:

Biodegradable plastics are the plastics that completely degrade in the environment. This is done by microorganisms that disintegrate and break down the structure of the biodegradable plastics. Manufacturers are able to create biodegradable polymers by using both renewable and non-renewable petroleum-based polymers, using corn, sugar, or sugarcane. Analysts estimate that the market of biodegradable plastics will grow by a CAGR of 11.49 percent between 2018 and 2026.

The future timeframe of the study is between 2018 and 2026, whereas 2017 will be the base year of the study. The aspects that affect market expansion include the following:

The production of raw materials is increased.

It is not difficult to find bio-based raw materials that could be converted into biodegradable polymers.

Creating a focus on good plastic waste management or disposal.

Efforts by legislation to encourage the use of less-polymers based on petroleum.

The packaging materials that are environmentally friendly are in high demand.

New applications of biodegradable plastics.

The trend of environmentally friendly products is still there in the world.

Frequently Asked Questions

1. What are biodegradable plastics, and how are they different from traditional plastics?

Manufacturers make biodegradable plastics from renewable resources like corn, and these plastics decompose naturally within months. In contrast, traditional plastics, which rely on petroleum, take hundreds of years to degrade. Biodegradable plastics are not only environmentally friendly but also cost-effective.

2. Can biodegradable plastics completely replace traditional plastics?

Manufacturers do not design biodegradable plastics to fully replace traditional plastics like polypropylene (PP) or polyethylene terephthalate (PET). Instead, they create them to complement these materials and use them alongside traditional plastics in various applications.

3. What are the main uses of biodegradable plastic made from corn?

Corn-based biodegradable plastics are used for making:

- Packaging materials

- Supermarket bags

- Water bottles

- Films and containers

- Disposable utensils and more

Their use helps reduce single-use plastic waste and supports eco-friendly consumption.

4. How is biodegradable plastic from corn manufactured?

The manufacturing process involves:

- Producing corn as the raw material

- Adding a catalyst and creating uniform degradable polymers

- Applying high pressure and using a reactor to form the base plastic

- Mixing binders, colorants, and additives to create finished products

- Packaging the products for sale

5. What are the benefits of using corn-based biodegradable plastics?

- Cost-effective: Cheaper than traditional plastics like polythene

- Eco-friendly: 100% natural and non-toxic

- Reduces landfill waste

- Enhances soil fertility through slow-releasing nitrogen

- Strong and versatile: Suitable for toys, containers, utensils, and more

- Less energy-intensive production compared to petroleum-based plastics