Bleaching powder, also known as calcium hypochlorite, is one of the most commonly used chemical compounds worldwide. It is essential in sanitation, water treatment, textile processing, and cleaning industries. In India and other countries, bleaching powder has a steady demand because of its various applications in households, businesses, and public health programs.

As people become more aware of hygiene, the need for safe drinking water and industrial cleaning grows. This increasing demand offers a great opportunity for entrepreneurs and startups interested in the chemical manufacturing sector. This article explores bleaching powder, covering its manufacturing process, what drives its demand, market potential, and opportunities for entrepreneurs. It also discusses how consultancy support can help new businesses succeed.

What is Bleaching Powder?

Bleaching powder is a pale yellowish-white powder with a strong chlorine smell. Its chemical name is calcium oxychloride (Ca(OCl)₂), and it is created by reacting chlorine gas with dry slaked lime (calcium hydroxide). Its powerful oxidizing and disinfecting properties make it an important ingredient in sanitation and bleaching.

It is widely used as a disinfectant for purifying water, for bleaching textiles and paper, and as a sanitizer at home and in industries. Its affordability and effectiveness lead to broad use in both rural and urban markets.

Historical Context and Importance

Bleaching powder has been used since the late 18th century, starting in Scotland. It has played a vital role in public health, particularly in treating water to combat diseases like cholera and typhoid. In India, bleaching powder became essential in municipal sanitation programs and industries due to its low cost and availability.

Even today, despite competition from newer disinfectants and chemicals for water treatment, bleaching powder remains significant because of its simplicity and broad acceptance.

Detailed project report on Bleaching powder

Market Size and Forecast

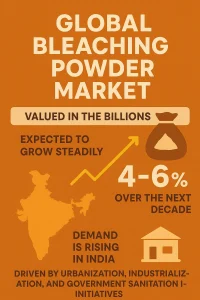

The global bleaching powder market holds a value in the billions and will grow steadily at a CAGR of about 4 to 6% over the next decade. In India, demand is rising, driven by urbanization, industrialization, and government sanitation initiatives.

The use of bleaching powder in water treatment plants, textile mills, paper industries, and rural sanitation programs creates a strong foundation for demand. With the government’s “Clean India” (Swachh Bharat Abhiyan) and safe drinking water initiatives, the need for bleaching powder is likely to increase in urban and rural areas.

Key Demand Drivers

Several factors contribute to the increasing demand for bleaching powder in India and beyond. The needs for water treatment, public health programs, and the textile and paper industries are key drivers, along with their affordability, accessibility, and growing awareness of hygiene.

To explore more, check our books

Applications of Bleaching Powder

Industries and households use bleaching powder for water purification, textile processing, paper bleaching, cleaning and sanitation, and chemical production, which ensures stable demand.

Manufacturing Process of Bleaching Powder

Producing bleaching powder is simple, but it requires controlled conditions and safety measures. The process involves preparing raw materials, reacting chlorine gas with dry slaked lime, collecting the product, packaging it in moisture-proof containers, and storing it properly to maintain its stability.

Quality and Safety Considerations

Bleaching powder, as a strong oxidizing agent, needs strict safety measures in manufacturing. Proper ventilation, protective gear, and monitoring of chlorine gas emissions are crucial. Keeping a consistent chlorine content is also important for efficiency.

Related articles:- How to start a Production of Sodium Metabisulfite

Challenges in the Industry

The bleaching powder industry faces challenges such as competition from alternatives like sodium hypochlorite, storage problems because of moisture sensitivity, compliance with regulations for handling chlorine gas, and a lack of user awareness about correct dosage and application.

Opportunities for Entrepreneurs

Despite these challenges, entrepreneurs can find opportunities in rural sanitation efforts, water treatment plants, packaging innovations, export markets, and the creation of value-added disinfectant products.

Role of NPCS in Supporting Startups

Niir Project Consultancy Services (NPCS) provides detailed market surveys, feasibility reports, financial planning, plant setup guidance, and compliance support for those entering the bleaching powder manufacturing field. These consultancy services help reduce risks and boost chances of success.

Future Outlook

The future of the bleaching powder market looks bright, especially in developing countries. Growing awareness of hygiene, urban development, and safe water initiatives will maintain demand. While modern alternatives may grow, bleaching powder will remain a widely accepted, cost-effective disinfectant.

Conclusion

Bleaching powder is one of the most reliable and affordable disinfectants, used in homes, industries, and public health. Its steady demand, simple manufacturing process, and wide use make it an attractive prospect for entrepreneurs in the chemical industry.

By understanding market trends, production needs, and challenges, startups can plan effectively. With expert guidance from consultancy services like NPCS, entrepreneurs can maximize the potential of bleaching powder manufacturing.

Discover the best business ideas for yourself by using our startup selector tools

Frequently Asked Questions

Q1. What is bleaching powder commonly used for?

It is widely used for water treatment, textile bleaching, the paper industries, and as a disinfectant.

Q2. What are the raw materials required for bleaching powder production?

The key raw material is chlorine gas, which reacts with dry slaked lime.

Q3. Is bleaching powder production environmentally safe?

Proper emission control and waste management are necessary to minimize environmental risks.

Q4. Which industries generate the highest demand for bleaching powder?

Water treatment plants, textile manufacturers, and paper industries are major consumers.

Q5. What is the future demand outlook for bleaching powder?

With rising sanitation needs and urbanization, demand is expected to grow steadily in India and abroad.