By running an electric current through copper, electrorefining removes contaminants by placing a copper cathode in an electrolyte bath and applying an electric current to extract pure metal. The process also generates hydrogen gas, which manufacturers can use to produce ammonia or reduce iron ore.

Visit this Page for More Information: Start a Business in the Copper Industry

Uses and Applications:

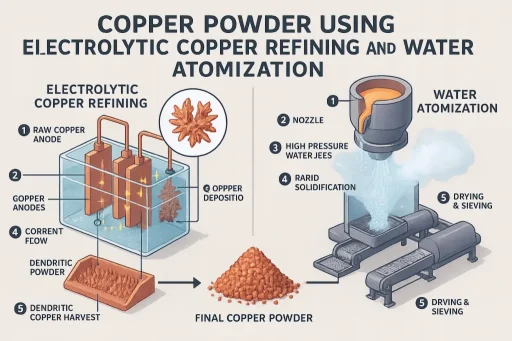

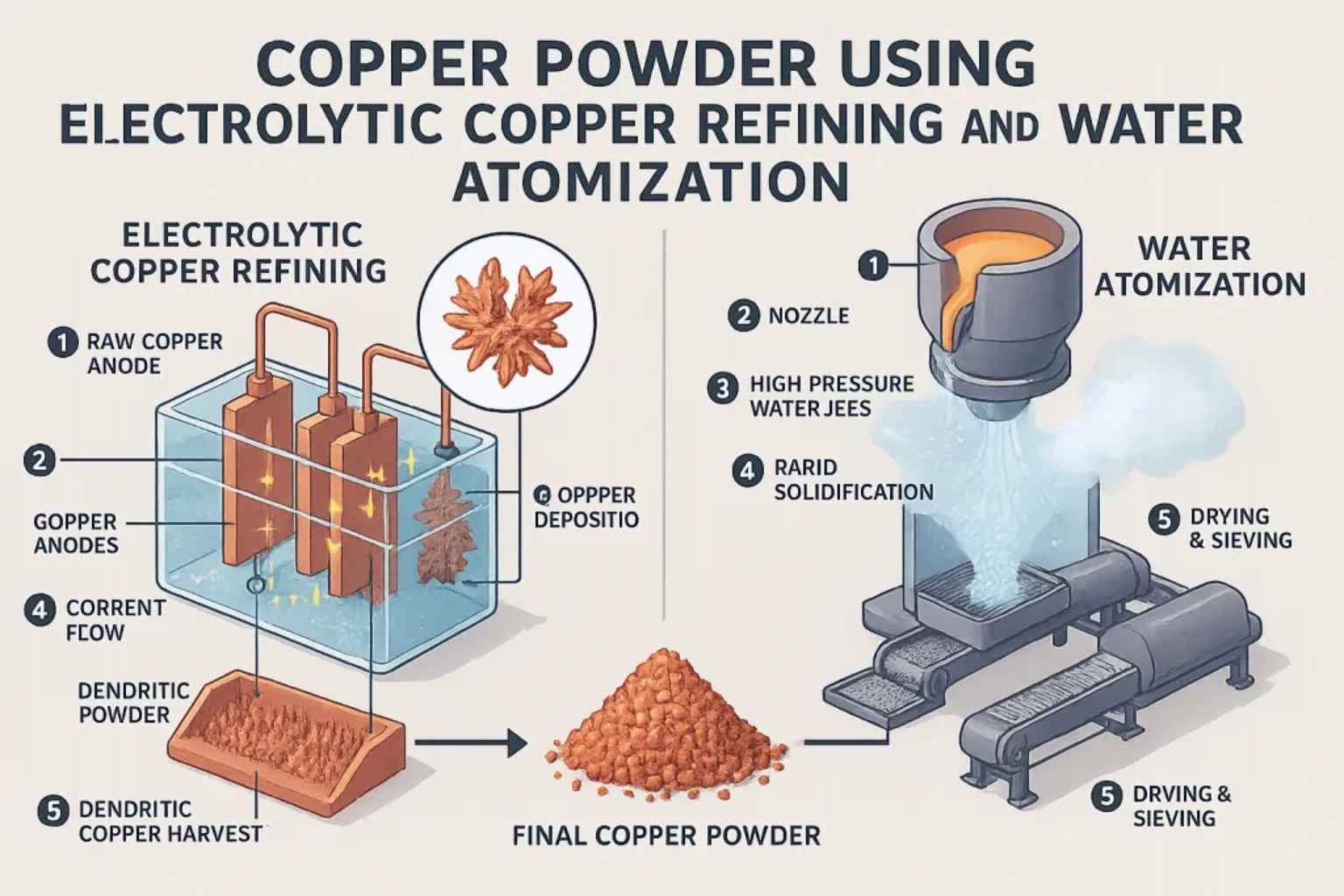

One of the primary technologies for creating high-quality copper powder is electrolytic copper refining. The process generates pure, high-quality copper with minimal impurities, which manufacturers use to produce a variety of products. It involves several steps, including electrolysis treatment, anode oxidation, and slag removal.

Electric current travels through the electrochemical cell containing the molten electrolyte during the electrolytic treatment stage (usually sulfuric acid).

The electric current causes some metal ions in the liquid, such as copper ions, to form an electrical double layer on the cathode electrode’s surface. These ions then migrate across the layer toward the oppositely charged anode electrode and convert into metallic copper upon contact. Other ion particles are also present in the electrolyte at the same time.

Related Business Plan: Copper Powder Using Electrolytic Copper Refining and Water Atomization Technology

Manufacturing Process:

The most common process for purifying copper is electrolysis, which involves running an electric current through copper-containing material. The type of electrolysis that takes place depends on whether the substance is solid or liquid. You must add water before placing a solid substance, such as copper oxide, into an electrolysis cell. If the substance is a liquid, like molten copper sulphate solution, there is no need to prepare it beforehand.

The two cell types employed in electrolysis are mercury cells and diaphragm cells. Diaphragm cells cost less to construct but produce less power than mercury cells, which need considerable resources to develop. One company has developed technology that reduces the requirement for electricity by splitting water molecules into hydrogen and oxygen using a hydrogen evolution reaction (HER) catalyst. Energy is also produced by the HER catalyst.

Read Similar Articles: COPPER PRODUCTS

Benefits of Starting a Plant for Copper Powder Using Electrolytic Copper Refining and Water Atomization Technology:

Starting a Copper Powder Plant with Electrolytic Copper Refining and Water Atomization Technology offers several key advantages. These include:

The technology effectively reduces costs and makes it a cost-efficient solution for manufacturers.

Secondly, the method promotes sustainability, aligning with eco-friendly industrial practices.

It also fulfills a significant market requirement for copper powder, which is in high demand across various sectors.

It offers a cleaner alternative to traditional copper refining methods, thereby minimizing environmental damage.

Furthermore, the process uses materials that benefit the environment, further supporting green initiatives.

Engineers can also easily construct the technology using readily available components, making it both practical and affordable.

The procedure protects the environment by recycling water and generating hydrogen gas, which can be used to power engines or fuel cells.

At the same time, it addresses a crucial market gap by supplying copper powder widely used in semiconductors and electrical conductors.

On the other hand, sulfur dioxide—one of the pollutants from traditional methods—contributes to acid rain, which harms plant life and increases soil acidity. This technology helps reduce that risk.

Finally, the process relies on environmentally friendly substances like air, hydrochloric acid, chlorine gas, refined alumina (a clay mineral), soda ash (a type of salt), and aluminium oxide, all of which are less harmful compared to traditional materials used in copper refining.

The technology effectively reduces costs, making it an attractive option for manufacturers. Moreover, the method promotes sustainability, aligning with global environmental goals.

It also fulfills a significant market demand for copper powder, which continues to grow across various industries. Offers a cleaner alternative to traditional copper refining methods, thereby reducing environmental impact.

The process uses materials that benefit the environment, contributing to greener manufacturing practices. Engineers can easily build the technology using readily available components, which further enhances its affordability and scalability.

At the same time, it addresses a crucial market gap by supplying copper powder, which is widely used in the production of semiconductors and electrical conductors.

Market Size in India:

India is a major market for copper, both in production and consumption. Historical data showed growth in production around the mid-2010s (for example, a rise from about 2.8 million to 3.2 million metric tonnes between 2014 and 2015), and demand climbed after 2015 as trade dynamics shifted. Overall, domestic consumption is large and still expanding, making the country a promising place to invest in copper-powder capacity.

This technology is cost-efficient, environmentally friendlier, technically achievable, and well-timed to meet rising demand for copper powder in high-value industries. It’s a practical way for manufacturers to boost margins while aligning with greener manufacturing goals.

Related Feasibility Study Reports: How To Start A Copper Powder Manufacturing Business Using Electrolytic Copper Refining And Water Atomization Technology

Global Market Outlook:

Analysts project the copper powder market to grow at a 4.22% CAGR, reaching USD 941.52 million by 2030. Industries are increasingly demanding copper powder for surface coating, powder metallurgy, and applications in automotive, aerospace, steel, oil & gas, and power generation.

Manufacturers also use it as a biocide in marine paints and rely on it for electronics, industrial equipment, and 3D printing. However, fluctuating raw material prices may hinder growth.

Frequently Asked Questions

1. What is electrolytic copper refining?

Electrolytic copper refining is a method that uses electric current to purify copper by removing impurities. The process involves placing a copper cathode in an electrolyte bath and passing electricity through it, which results in the extraction of high-quality copper.

2. What are the main steps in the electrolytic copper refining process?

The process includes:

- Electrolysis treatment

- Anode oxidation

- Slag removal

3. Why is copper powder important?

- Electronics

- Semiconductors

- Automotive and aerospace

- Steel, oil & gas

- Power generation

- 3D printing and surface coating

- As a biocide in marine paints

4. What are the benefits of using this technology for copper powder manufacturing?

Key advantages include:

- Cost-effectiveness

- Sustainability

- Fills a critical market gap

- Produces cleaner copper compared to traditional methods

- Uses eco-friendly raw materials

- Recycles water and generates hydrogen gas for industrial use

- Reduces sulfur dioxide emissions

5. What is water atomization technology, and how does it support copper powder production?

Water atomization technology involves spraying water onto molten copper to produce fine powder particles. When combined with electrolytic refining, it enhances production efficiency and reduces maintenance costs.

6. What eco-friendly materials are used in this process?

The process uses:

- Air

- Hydrochloric acid

- Chlorine gas

- Refined alumina (a clay mineral)

- Soda ash (a type of salt)

- Aluminium oxide

The copper refining process by electrolyzing is very useful to get the purer form of the copper, the by product Hydrogen is also useful in other chemical process, thank you for sharing this blog post.