Starting a manufacturing business for aluminium cans used in beverages can be highly lucrative and rewarding. Aluminium cans have become the packaging choice of the beverage industry due to their durability, lightweight nature, and recyclability. They are widely used for carbonated drinks, mineral water, beer, and other non-alcoholic beverages. Entrepreneurs who want to enter this sector need to understand market demand, production costs, and legal regulations. Similarly, exploring opportunities such as the Manufacturing Business of Activated Carbon can also prove profitable, as both industries cater to high-demand markets with significant growth potential.

Access to quality equipment and skilled personnel is essential for a smooth production process. With the right preparation, a solid business plan, and expert guidance from services like NIIR Project Consultancy Services (NPCS), one can establish a profitable aluminium can manufacturing venture.

Detailed project report

Market Demand and Growth

Understanding the market is the first step. Aluminium cans are preferred because they are easy to transport, keep beverages fresh longer, and can be recycled multiple times. Large beverage manufacturers benefit from reduced shipping costs, while environmentally conscious consumers appreciate the sustainability aspect. Market research helps identify competition, forecast demand, and plan production schedules efficiently. Regional and seasonal variations in beverage consumption must also be analyzed to optimize supply and maximize profits.

Regulatory and Compliance Needs

Legal and regulatory compliance is critical. Entrepreneurs must follow standards such as Can-Enders-In-Gross (CEIG), a voluntary agreement that holds manufacturers accountable for damages caused by defective cans. They also need food safety certifications like HACCP to maintain hygiene standards and must understand the FDA Food Code to ensure full regulatory compliance. These measures protect both consumers and businesses and build credibility in the market.

Sourcing resources and equipment is the next step. Entrepreneurs need high-quality aluminium sheets or billets and reliable manufacturers to ensure consistency and compliance with food safety standards. A packing and distribution network is essential to deliver products to beverage companies efficiently. Skilled staff, including machine operators, quality inspectors, and logistics personnel, are crucial to maintaining production flow and product quality. Proper resource management ensures smooth operations and minimizes production delays.

Manufacturing Process

The aluminium can manufacturing process involves melting aluminium in a furnace to form billets, rolling them in hot and cold mills to achieve desired thickness, and softening sheets through annealing. Manufacturers punch circular blanks, form them into cylindrical shapes, and curl the edges. Seaming machines then join the edges to create finished cans, which are rinsed, dried, and carefully inspected for defects. Every step requires precision to maintain high standards and ensure customer satisfaction.

Marketing and distribution are equally important. Entrepreneurs should network with beverage companies, attend industry trade shows, and leverage online platforms to expand reach. Establishing a strong brand with an attractive logo, slogan, and packaging design helps create customer loyalty. With the right strategy, aluminium cans manufacturing can be profitable while contributing to sustainable packaging solutions.

Detailed project report

Potassium Chloride Manufacturing

Potassium chloride is a versatile chemical widely used as a fertilizer, food additive, and pharmaceutical ingredient. Its demand is increasing due to its importance across multiple industries. Entrepreneurs looking to manufacture potassium chloride must consider production methods, market demand, and resource availability. NPCS provides detailed project reports and business plans for those seeking to enter this sector, helping mitigate risks and identify opportunities.

The primary manufacturing methods include extraction from brine and production from wastewater. Brine extraction is simpler, requiring minimal licensing, but demands access to high-quality brine sources. Wastewater processing involves ion-exchange methods and may require more sophisticated equipment. Choosing the right method depends on local resources, production scale, and regulatory requirements.

To explore more, check our books

Market Demand and Applications

Potassium chloride enjoys consistent demand across agriculture, food processing, water treatment, pharmaceuticals, and other industries. Its use as a fertilizer ensures steady market growth, while food and pharmaceutical applications expand opportunities. Entrepreneurs must research market trends, competitors, and regional demand to capture market share effectively.

Location selection is crucial. Areas with abundant raw materials, such as sylvite and carnallite, reduce production costs and improve product purity. Proximity to customers lowers transportation expenses, which is significant since potassium chloride is heavy and bulky. Efficient supply chains and logistics further enhance profitability.

Despite its stability, manufacturing potassium chloride has challenges. Securing reliable brine sources, finding skilled personnel, and acquiring suitable equipment are common obstacles. Regulatory compliance in chemical handling, storage, and safety must also be ensured. With careful planning and strategic execution, entrepreneurs can build a profitable potassium chloride manufacturing business that serves multiple high-demand sectors.

Bio-Plastics: Starch-Based Alternatives

Advantages of Bio-Plastics

Starch-based bio-plastics are widely used in packaging, disposable cups, straws, plates, toys, and textile fibers. Their biodegradability makes them ideal for single-use applications. Thermoplastic starch (TPS) is flexible, biodegradable, and can be combined with other polymers to enhance strength and durability. Industries can produce these plastics using existing extrusion and molding machines, lowering the entry barrier for adopting eco-friendly practices.

Manufacturing bio-plastics begins with breaking down starch to make it suitable for thermoplastic processing. Plasticizers like glycerol and water improve viscosity, while additional biopolymers such as polylactic acid (PLA) or polyhydroxy butyrate (PHB) enhance tensile strength. The material can then be molded into films, containers, and rigid products. Corn starch-based PLA is particularly popular for packaging due to its affordability, ease of growth, and compostability.

The demand for bio-plastics is driven by environmental consciousness, legal regulations, and consumer preference for sustainable products. Governments worldwide have imposed restrictions on conventional plastics, increasing demand for alternatives. Bioplastics reduce reliance on fossil fuels, lower carbon footprints, and contribute to better waste management. Entrepreneurs entering this sector can leverage market trends to create products that meet both business and environmental goals.

Related article:- How to Start a Manufacturing Business of Bamboo Charcoal

Market Potential and Profitability

Aluminium cans, potassium chloride, and bio-plastics all represent sectors with robust market potential. Aluminium cans benefit from consistent beverage industry demand and sustainability trends. Potassium chloride enjoys cross-sector applications and steady growth due to its essential role in agriculture and food processing. Bio-plastics capture the growing consumer and regulatory push for environmentally friendly materials. Businesses entering these markets can achieve profitability through strategic location selection, quality production, and strong marketing.

Sustainability adds value across all three sectors. Aluminium cans are recyclable, bio-plastics are compostable, and potassium chloride contributes to agricultural productivity. Companies that adopt eco-friendly practices not only reduce environmental impact but also appeal to conscious consumers. Combining profitability with sustainability creates a competitive advantage in modern markets.

Role of NIIR in Business Planning

NIIR Project Consultancy Services (NPCS) provides entrepreneurs with comprehensive project reports, feasibility studies, and market analysis. NPCS guidance covers raw material sourcing, production technology, financial projections, and regulatory compliance. With expert advice from NPCS, businesses can navigate industry challenges, optimize investments, and identify growth opportunities. Using NPCS resources significantly improves decision-making and reduces the risk of failure.

Conclusion

Manufacturing aluminium cans, potassium chloride, or starch-based bio-plastics offers lucrative opportunities for entrepreneurs. Each sector has distinct advantages, from steady demand and profitability to sustainability and innovation. Success requires careful market research, regulatory compliance, strategic planning, and effective marketing.

Partnering with NIIR Project Consultancy Services provides expert insights, project reports, and data-driven guidance to enhance decision-making and operational efficiency. With dedication, proper preparation, and informed strategies, entrepreneurs can build thriving businesses that deliver value, growth, and sustainability across these high-potential industries.

Discover the best business ideas for yourself using our startup selector tools.

Frequently Asked Questions

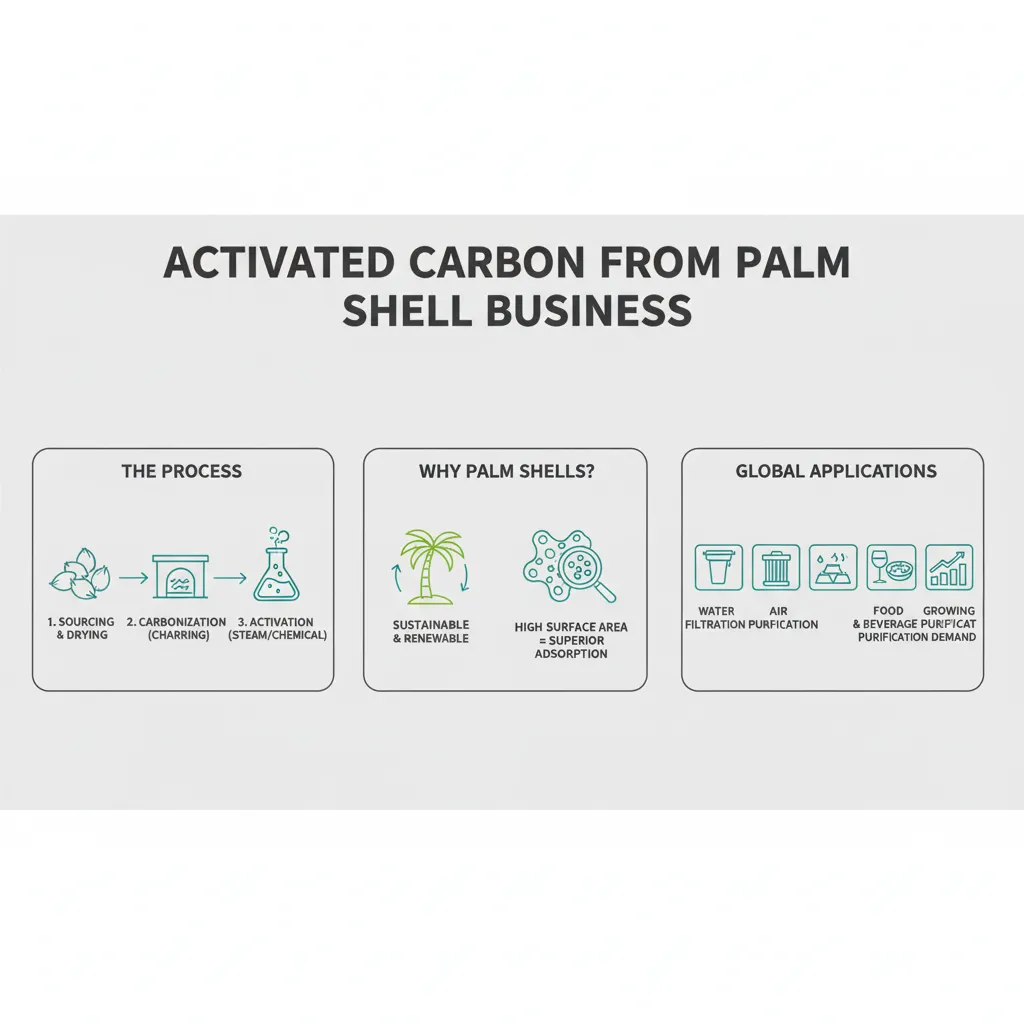

How is activated carbon made from palm shells?

The process involves two main stages: carbonization and activation. First, palm shells are heated in a furnace with limited oxygen to turn them into charcoal (carbonization). Then, the charcoal is treated with high-temperature steam or chemical agents to create a porous structure (activation), which greatly increases its surface area.

Why are palm shells a sustainable source for activated carbon?

Palm shells are a by-product of the palm oil industry, which makes them a renewable and abundant source of biomass. Utilizing this agricultural waste for activated carbon production adds value to a waste product and reduces the need for non-renewable raw materials.

What are the main applications of activated carbon from palm shells?

Due to its high quality and purity, activated carbon from palm shells is used in a wide range of applications, including water and air purification, gold recovery, and the food and beverage industry for decolorization and purification.

What is the primary difference between granular and powdered activated carbon?

Granular activated carbon (GAC) consists of larger, irregularly shaped particles and is typically used in columns for continuous flow systems like water filters. Powdered activated carbon (PAC) is a very fine powder used for batch processes, such as in food and pharmaceutical purification.

What are the key challenges in the activated carbon business?

Key challenges include the high energy consumption of the activation process, competition from other raw materials like coal and coconut shells, and the need for consistent sourcing of quality palm shells to ensure a stable supply.