Far beyond just a color, paint is a multi-purpose coating that can protect surfaces from damage and change the atmosphere. Paint is widely used in offices, homes, cars, and factories. This liquid is produced by very complex industrial and scientific processes.

Although important to the general public, the painting production steps are very important for investors and entrepreneurs because this information impacts their decisions. The right combination of marketing, quality control and technology can build a great paint brand in the market.

Read Our Books: Click Here

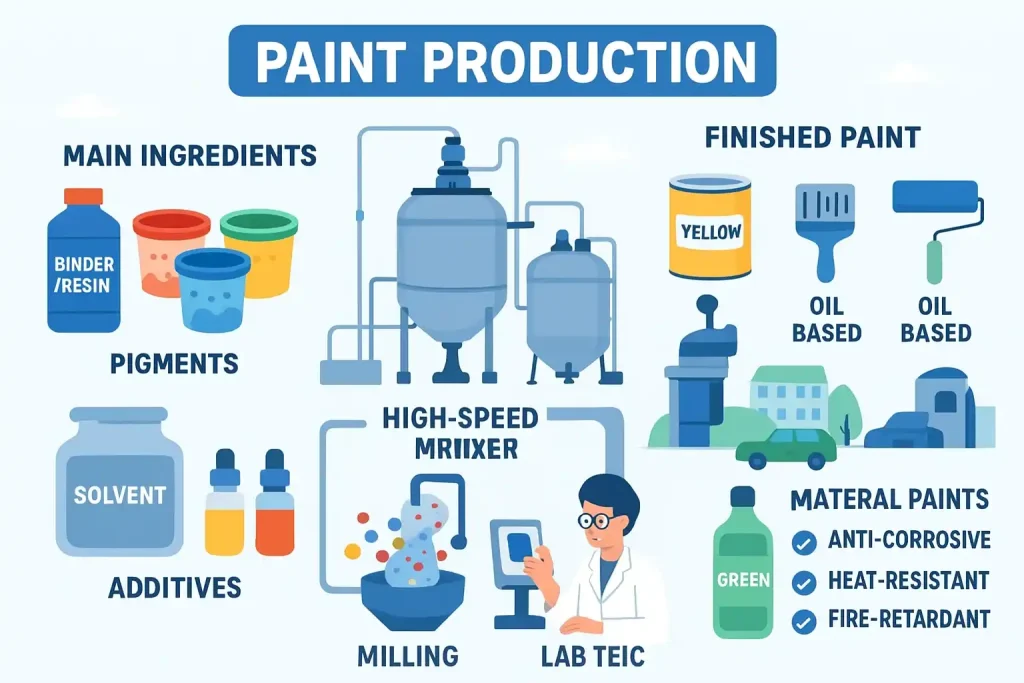

Ingredients for making paint

Paint quality and effectiveness depend directly on the ingredients it contains. Every ingredient plays a different role to make paint durable, beautiful and easy to use.

The “glue” of paint is resin or binder, binding the color particles and adhering them to the surface. When dried, it forms a film, aiding the color in duration. The type of binder usually varies with the kind of paint.

Water paints are characterized by using acrylic or latex binders which fast dry and low odor easy to work with. Oil-based paints use alkyd binders, which are smooth to apply and adhere well to both wood and metal surfaces. As needed, durability and chemical resistance would usually require epoxy or polyurethane type binders.

Read More: A Startup’s Guide to the Coatings Industry for A Profitable Future — NIIR

Pigment makes the paint aestheticized and would usually serve as a lively lifeblood. Everybody makes use of titanium oxide to manufacture bright white paint. For iron oxide paints-red, yellow or brown-the oxides produce broad ranges of those color combinations.

Without it, cool tones of blue and green will not come about. Even in order to lessen costs, talc or calcium carbonate can be added. All in all, these paint formulas are where the real game is!

The solvent or carrier liquefies the paint, making it easy to apply. Mineral spirits or mineral water are added to oil-based paints. The first will evaporate when the application of paint is finished, leaving only the paint coating. Paints, in particular, have several minor portions of additives.

For example, dispersants can spread the pigment, defoamers generally have full subscription towards the thickness, rheology moderators affect and measure the surface tension, while dryers or catalysts mostly speed up the drying time; and biocides or antifungal are also referred to as growth stoppers for fungi.

Paint Manufacturing Process

All of the paint-producing process steps are very well planned and executed until the end.

First, chemists need to create a recipe which includes the precise calculation of the amounts of materials. The ingredients are mixed in the large tanks for a binders and solvents, followed by primary additives.

Pre-mixing involves the addition of pigments and fillers and using a high speed mixer to achieve a homogeneous mixture. In this way, the larger particles in the mixture are removed and smoothened.-

Dispersion step or milling would create a paint that pigment particles crashed to such drain size; And distributed evenly with a bead or sandmill. The paint is smoother, and the quality of color increases.

The mixture will directly transfer into another tank after the milling process is complete. Here, I add other additives, binders, and solvents if needed-this is how I maintain the color density and quality.

Then, the manufacturer tests the quality of the created paint before releasing it to the market. I analyze everything: color density, coverage, brightness, VOC or chemical content as well as shelf life.

If everything is in order, they filter the paint through a micron-sized filter. Then it pours into a tin or bucket and labels it with the batch number, production date, expiration date, and color name.

Read Our Project Report: Click Here

Besides these, there are various other types of paint

There are different types of paints available.

Water-soluble paints are, by far, the most common for interior and exterior applications. This form of paint uses water as the main solvent. The benefits of this type of paint consist mainly in the following: it is low in odor, quick-drying, and environment friendly, having lower content of noxious chemicals.

Oil paints are used for metal and woodwork or outside. Binders of oil provide a bright and smooth finish. It takes a lot of time for this paint to dry up. It has, however, a long lifespan and does not get ruined by moisture and sunlight.

Industrial paint is that type of paint used solely in the industrial and manufacturing industry. It comprises properties that resist chemicals, sustain wear and tear, and perform in extreme conditions. This would be ideal for metallic protection, pipes, special parts, or any other part of machinery.

Moreover, there are special paints, specifically designed to meet specific needs. Heat-resistant and anti-corrosive paints, for instance, are excellent in protecting metals against corrosion and rust. Fire-retardant and anti-corrosive types slow the flow of fuel in a fire.

Read More: Your Complete Guide to Thinners and Solvents Industry.

Paint manufacturing business

Paint manufacturing is a lucrative and promising business, but for success, you need both technical and market knowledge.

Initial investment for a new business will include various machines and equipment. Such as milling machines, mixers, filters, packaging equipment, and lab equipment. Paint production is impossible without these machines.

Raw materials account for 50-70% the cost of production. The quality and control of raw materials are therefore important in determining profitability. The quality of paint, the number of colors and the strength or the dealer network are all important to compete in the market.

Consumers quickly accept paints with low odor, fast drying, long-lasting coverage and anti-bacterial or eco-friendly properties. Paints that have low odors, quick drying, long lasting coverage, anti-bacterial, or eco-friendly qualities quickly gain market acceptance.

The right market strategy and technological aspects help to make the paint business successful and profitable.Conclusion

Find the Best Idea for Yourself With our Startup Selector Tool

Conclusion

Paint production is a scientifical process. The right formula and quality testing, along with advanced technology is necessary to create quality paints. The construction industry is growing and this is a lucrative business. Entrepreneurs can succeed in this field if they understand the needs of their customers and introduce paints that have new features.

How is Paint Made: FAQ

Question 1: What is the difference between water-based and oil-based paints?

Answer: Water-based paints use water, dry quickly and have less odor. Oil-based paints contain solvents, give a smooth finish but take longer to dry.

Question 2: How is the color of paint accurate?

Answer: The color is determined using a spectrophotometer and, if necessary, the correct color is created with tinting paste.

Question 3: What is the shelf life of paint?

Answer: Paint is usually usable for 12-24 months if stored properly.

Question 4: What is VOC and why is it important?

Answer: VOC is a volatile organic compound. It can be harmful to both the environment and health. Low-VOC paints are popular with consumers.

Question 5: Can small business owners succeed in the paint industry?

Answer: Yes, you can start on a small scale. It is possible to succeed if you maintain the right market strategy and standards.