Calcium-based stabilizers (like Ca-Zn) are mainly utilized in cables and wires, in the window and specialized profiles (also foamed ones), and also in any pipes (like dirt and sewer pipes, foam core pipes, pressure pipes, corrugated pipes, property drainage pipes and cable ducting) in addition to the corresponding fittings.

Calcium-based stabilizers also have been released in PVC stiff calendering movie production when enhanced organoleptic characteristics are needed, for example, instead of tin mercaptides in translucent food packaging program or instead of tin carboxylates in PVC dismissed movies shrinkable and for candies wrapping. In the same way, calcium-based stabilizers are an alternative to Liquid Mixed Metals (LMM) for much flexible software, particularly for the indoor ones, if strict air quality requirements are set up (VOC).

Related Projects:- Calcium & Zinc Stabilizers

Calcium Zinc Stabilizers are frequently utilized in PVC rigid and elastic objects. Calcium Zinc Stabilizers are used to produce products like pipes, health programs, footwear, wires, and profiles since it’s a metal-free stabilizer. Calcium Zinc Stabilizers will also be acceptable for food and non-toxic grade PVC items which need FDA and similar acceptance under food regulatory functions. With higher heat stability, again, it supplies low odor, and also the most persuasive feature of Vitamin Zinc Stabilizers is they are highly economical.

The usage of calcium/zinc stabilizer systems was prevalent in PVC. Due to the qualities of calcium/zinc stabilized materials, they’re frequently utilized in several rigid and flexible PVC applications. This stabilizing system may give products with a high level of clarity, good electrical and mechanical properties, excellent organoleptic properties, and great outdoor weather ability.

Vitamin Zinc Stabilizer is stringently tested on several different parameters of quality to guarantee quality. Offered range may be utilized in a wide assortment of programs such as toys, health care products, including blood bags, semi-rigid, and flexible foil for food packaging. Calcium/zinc stabilizers are used in a vast assortment of applications. These include toys, healthcare products, including blood bags, semi-rigid and flexible foil for food packaging, bottles such as potable water, in addition to for potable water pipes.

Related Books:- Chemical Technology (Organic, Inorganic, Industrial), Fine Chemicals

Why Choose the Calcium & Zinc Stabilizers Manufacturing Business?

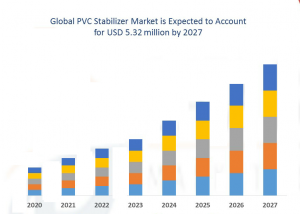

The international marketplace for stabilizers to grow. US$5.3 billion in 2021. Calcium Zinc stabilizers for PVC are utilized directly or mix to protect against various effects such as the direct or indirect effect of heat and ultraviolet light. This can be a lead-free stabilizer for the past 10 to 15 years because of environmental and health concerns. Its consumption is growing in Europe, the USA, and Asia.

Calcium, zinc, and lead are some of the dominant product sections for stabilizers. Magnesium established stabilizers dominate the international requirement for stabilizers, and the tendency is expected to continue throughout the forecast period. Cadmium-selected stabilizers overlooked the worldwide need for stabilizers; however, cadmium was fully substituted with different materials like lead because of ecological issues. Magnesium and zinc stabilizers have excellent grip and control of viscosity and offer good original colouring and colour retention.

Related Videos:- Chemicals (Organic, Inorganic, Industrial)

Conclusion

The project report from NPCS on Calcium & Zinc Stabilizers, Comprehensive Project Report, Profile, Business Plan, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Price and Revenue is a record in which you can get to learn about the current and predict market. Each of the information offered in the project report is assessed and assessed together with the business players.

EVA_Art2021