Some of the most sustainable and profitable companies are quiet organizations producing products that the world needs daily. Evergreen businesses are built on a product portfolio that remains relevant regardless of economic cycles, consumer preferences, or technological changes.

Evergreen manufacturers don’t focus on trends; rather, they produce niche items such as packaging, construction products, hygiene consumables, agricultural inputs, chemicals, or basic household or industrial items. Since those products are used by generations of users, evergreen manufacturers enjoy a steady stream of orders compounded over the years and create a basis for a truly sustainable industrial business.

Basic Elements of a Resilient Evergreen Manufacturing Business

Evergreen models thrive because they address structural, rather than sentimental, demand. When manufacturers provide a high-quality product consistently, their customers will feel safe in continuing to deal with them, rather than perhaps try to buy extra product that may only be available to them from only one of several suppliers.

Broad, long-term macro-trends such as urbanization, changing lifestyles, consumer commitment to stricter rules, increased healthcare spending, and infrastructure development actively grow demand. Global manufacturing is expected to exceed USD 22 trillion by 2030 at a stabilizing over 4 percent growth rate. Entrepreneurs looking into evergreen categories such as medical disposables, biodegradable packaging, building composites, agro-inputs, warm and cold-pressed, or polymers could use the information of the manufacturing growth to model their viability from a manufacturing growth.

For more information, visit our project reports

Pillars of an Evergreen Manufacturing Model

Process Consistency

Repeatable, standardized processes ensure durable quality and provide avenues for lean optimizations to slowly build over time into powerful long-term profitability. Such companies aim for continuous and incremental improvements rather than a one-time overhaul.

Raw Material Security

Evergreen manufacturers seek to secure uninterrupted supplies to maintain production. They often enter into long-term contracts with multiple vetted suppliers to prevent stock-outs and price volatility.

Strong Market Relationships

Rather than being a one-off sale, these companies value institutional and trade customers. Technical support helps to build trustworthy relationships and ensures product customization, and thereby translates into dependable repeat ordering as opposed to one-off sporadic sales.

Technology Adaptability

Evergreen companies don’t have to be early adopters, but they do have to mature. These constitute industries that actively adopt technology in predictive maintenance, formulation eco-types, automation, emissions control, and digital ERP systems, allowing them to stay aligned with future demands without interruption.

High-Potential Evergreen Segments to Explore

Packaging materials continue to grow due to rising e-commerce and FMCG distribution, making cartons, corrugated boxes, and flexible wraps strong long-term opportunities. Building construction has seen a rise in demand for engineered wood substitutes, WPC boards, AAC blocks, and uPVC fittings in infrastructure and housing projects.

The demand for healthcare disposables continues to be paramount long after the pandemic due to demographic and lifestyle changes, such as artificial sanitary napkins, adult diapers, gloves, gowns, and masks. Agriculture-wise, a steady demand for micronutrients, mulch films, water-soluble fertilizers, and seed-treatment powders puts agro-input manufacturing classically evergreen.

Related articles:- How to Start a Profitable Cold Storage Business

Evergreen Manufacturing Process Framework

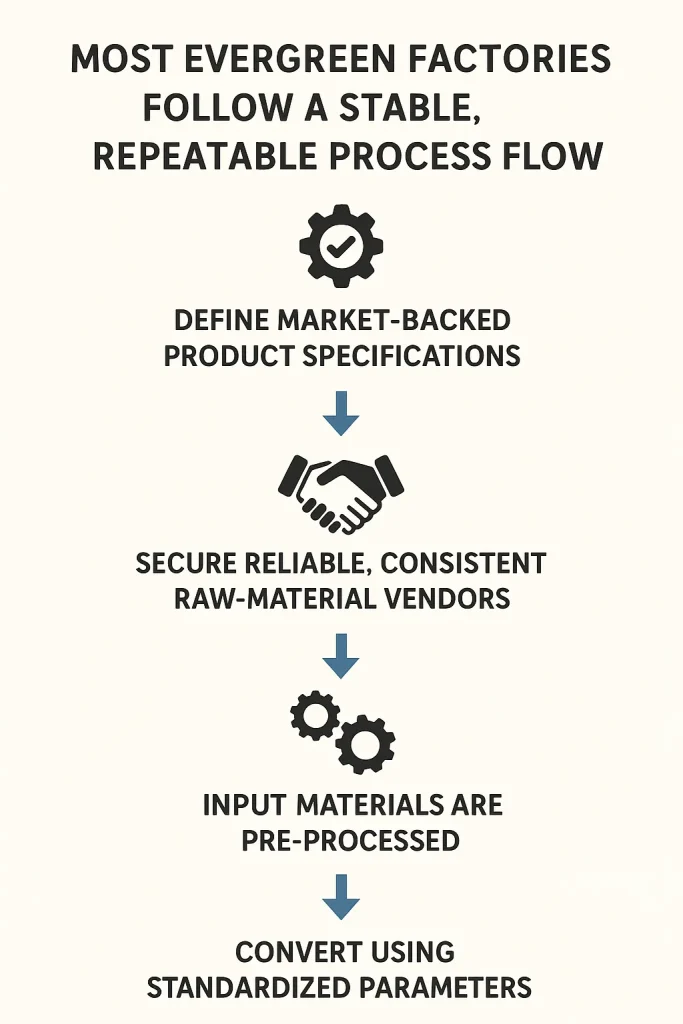

A majority of evergreen factories prefer a stable and repeatable process flow. It starts with market-backed product specifications and securing vendors who provide top-quality raw materials on a consistent basis. Input materials are generally pre-processed and transformed under standard parameters.

Conditional upon testing during production, the manufacturers finish packaging the product for immediate marketing and perform final QC checks before dispatching it to retain consistency. Products are then dispatched to distributors or institutional buyers who continue to place purchase orders. Instead of limiting the quality assurance to the finishing stage, they ensure the whole process is imbued with fairness and reliability, which are traits of the brand.

For more information visit our books

Strategies for Evergreen Growth, Long Term

Strategies for Evergreen Growth, Long-term Evergreen companies stay competitive by means of strategic supply-chain management, wherein a facility may be located closer to raw material or demand centers, to optimize inventory, and work with logistics providers of repute to cut down time and wastage.

They establish a flexible plant layout that takes into account the introduction of new product variants and efficiency improvements in technology without encountering big downtimes. A good number of them go for sustainment measures like making their plants water-recycling-oriented or using clean-energy systems; at times, this pays in higher valuations from buyers and eligibility for exports under specific environmental standards. Product customization provides another way to serve a number of buyers without affecting their core process economics. Variations might be size, color, density, or formulation.

Why Evergreen Businesses Perform Even During Downturns

Unlike trend-based sectors that suffer during economic slowdowns, evergreen manufacturers continue receiving baseline orders because their products are critical to fundamental human and industrial activity. Hospitals will keep needing disposable medical items, infrastructure maintenance will go on even when new projects slow, and farmers still require inputs each season.

These businesses rely on stable cash flow over flashy spikes, giving them resilience. Once processes and customer networks are mature in one region, entrepreneurs can duplicate the same model in new geographies, boosting revenue with lower learning curves.

NPCS – Helping Build Evergreen Manufacturers

Niir Project Consultancy Services (NPCS) prepares Market Survey cum Detailed Techno Economic Feasibility Reports tailored to such evergreen opportunities. Their reports include detailed information on raw materials, manufacturing processes, plant layouts, and projected financials. NPCS supports entrepreneurs in assessing the feasibility and success potential of launching new industrial ventures in high-demand evergreen niches.

Conclusion:

In manufacturing, prove that true industrial success lies in producing what the world steadily requires — not what momentarily excites it. Entrepreneurs who pick essential product lines, design reliable processes, and cultivate long-term supply and customer partnerships can create companies that grow quietly yet powerfully across decades.

In a global economy obsessed with disruption, the surest way to build wealth and legacy may still be to focus on what people, industries, and societies will never stop needing.

Find best business ideas for yourself using our startup selector tools

Frequently Asked Questions

1. What is meant by an evergreen business model in manufacturing?

An evergreen business model refers to a manufacturing setup that produces essential goods with consistent, long-term demand, allowing the business to operate profitably through changing market conditions without depending on trends or short-term fads.

2. Which manufacturing sectors are considered evergreen?

Packaging materials, building products, agro-inputs, intermediate chemicals, medical disposables, and basic consumer utility goods are some of the most resilient evergreen sectors because they meet ongoing societal and industrial needs.

3. Why are these less risky for new entrepreneurs?

Because these models serve structural demand, they tend to provide predictable cash flows and repeat purchase orders, reducing exposure to market volatility and offering greater financial stability over time.

4. How can a manufacturing business stay evergreen in the long term?

By maintaining high-quality, process-driven production, updating technology gradually, securing raw-material supply chains, and nurturing long-term buyer relationships instead of chasing short-lived trends.

5. Can small-scale manufacturers also build evergreen businesses?

Absolutely. By focusing on niche essential products and catering to steady local or regional demand, even small plants can develop evergreen models and scale gradually as orders grow.