Liquid paraffin oil, also known as mineral oil, is a clear, odorless, and stable product used in various sectors, including cosmetics, pharmaceuticals, food processing, and industrial lubrication. Its wide range of uses—from skin moisturizers and laxatives to protective coatings—makes it a promising venture for entrepreneurs. Whether you want to supply cosmetic formulators, pharmaceutical companies, or specialized industrial users, understanding this industry is crucial for a successful startup.

Market Forecast & Growth Trajectory

Market Volume & Value Trends

The demand for liquid paraffin oil is steadily increasing in both volume and value.

By weight, the global market was about 1,014 thousand tonnes in 2024, and it is expected to rise to around 1,607 thousand tonnes by 2035, with an average annual growth rate of approximately 5.09% (ChemAnalyst).

By value, industry estimates differ:

The paraffin oil market was valued at around USD 6.61 billion in 2024 and is projected to grow to USD 8.99 billion by 2034, with an average annual growth rate of about 3.1% (Market Research Future).

Another estimate places the global paraffin oil market at USD 2.5 billion in 2023, with an increase to USD 4.1 billion by 2032, showing an average annual growth rate of around 5.8% (Dataintelo).

While estimates vary depending on coverage (such as liquid paraffin versus overall paraffin), there is agreement on steady mid-single-digit growth over the next decade.

Demand Drivers Across Applications

Cosmetics & Personal Care: Liquid paraffin is a key emollient, particularly in skin creams, lotions, baby care, and hair oils. It represented about 48% of market share in personal care in 2024, with continued growth anticipated (ChemAnalyst, Dataintelo).

Pharmaceuticals: Often used as a lubricant in laxatives and ointments, this segment remains vital (Market Research Future, Allied Market Research).

Industrial & Food Processing: Acts as a release agent, lubricant, and coating, especially in machinery servicing food or pharmaceuticals (Market Research Future, MAXIMIZE MARKET RESEARCH).

Textiles, Packaging, & Other Sectors: Used in textiles for water resistance and in packaging to protect against moisture (Market Research Future).

Geographic Outlook

Asia-Pacific currently leads demand, particularly in cosmetics and industrial processing (Allied Market Research, Dataintelo). North America and Europe also maintain strong demand due to regulated standards and premium end-use markets (Market Research Future, Allied Market Research).

Detailed Project Report on liquid paraffin oil

Manufacturing Process Overview

Producing liquid paraffin oil involves refining mineral oil from crude oil distillation and applying further purification to create grades suitable for pharmaceutical or cosmetic use.

Refining & Fractionation

Crude Distillation: Overhead fractions are separated to isolate kerosene and heavier alkanes.

Solvent Dewaxing & Hydro-treating: Removes waxy components and unsaturated hydrocarbons to enhance clarity and stability.

Vacuum Distillation: Separates light and heavy paraffins, producing distinct product streams.

Purification & Grading

Pharma-/Cosmetic-Grade Processes: Removes impurities, odor compounds, and potential toxins.

Stabilization: Antioxidants or stabilizers may be added to maintain shelf life in certain grades.

Testing & Packaging

Quality Testing: Includes viscosity, refractive index, and microbiological safety checks.

Packaging: Inert containers or drums, often with a nitrogen blanket to prevent oxidation.

View our Handbooks for more information

Quality Assurance & Compliance

In refined sectors like pharmaceuticals or cosmetics, quality assurance is critical:

Pharmacopoeia Compliance: Meeting USP, BP, or IP standards ensures safety (Intel Market Research).

Purity Checks: Removing polycyclic aromatics and ensuring minimal sulfur content.

Microbiological Control: Ensuring sterility for topical products.

Batch Consistency: Maintaining detailed logs for viscosity, color, and odor.

Related articles: How to Start a Manufacturing Business of Chlorinated Paraffin Wax (CPW)

Sourcing & Raw Material Strategy

Crude Oil & Feedstock

Refinery Integration: In-house or contract supply from crude distillation ensures consistency.

Contract Blending: Partnering with petrochemical processors offers flexibility for startups.

Regulatory & Sustainability Considerations

Chemical Safety: Source from low heavy-metal refineries and follow environmental regulations.

Bio-Based Alternatives: Growing interest in sustainable, plant-based paraffin oils (Allied Market Research, Acumen Research and Consulting).

Packaging Considerations

Container Choice: Stainless-steel drums for pharma grade; steel or HDPE drums for industrial.

Labeling: Clearly indicate grade, batch number, and compliance certifications.

Storage: Use airtight, cool warehouses to prevent contamination.

Go-to-Market Strategy for Startups

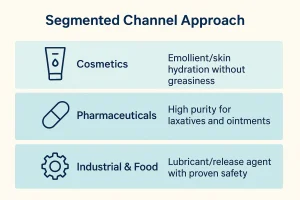

Segmented Channel Approach

| Target Market | Value Proposition |

|---|---|

| Cosmetics | Emollient/skin hydration without greasiness. |

| Pharmaceuticals | High purity for laxatives and ointments. |

| Industrial & Food | Lubricant/release agent with proven safety. |

Pharma-grade supply should be the starting point due to high entry barriers and trust-building potential. Later, expand into cosmetics and industrial markets for higher volume growth.

Compliance & Trust

Provide detailed specifications, safety data sheets, and stability data to build B2B buyer confidence.

Branding & Differentiation

Position as “High-purity mineral oil, compliant with USP/Ph. Eur.” or highlight traceability.

Challenges & Mitigation Strategies

Regulatory Hurdles: Pharma-grade certification requires a strong lab infrastructure.

Feedstock Volatility: Crude oil price fluctuations can impact margins.

Sustainability Pressure: Rising demand for eco-friendly alternatives.

Market Saturation: Compete by focusing on quality and flexibility.

Mitigation: Form certification partnerships, diversify feedstock sources, obtain premium-grade certifications early, and emphasize responsive customer service.

Why Liquid Paraffin Oil Is Startup-Friendly

Scalable Throughputs: Modular setups can start small and scale up.

Strong Regulatory Barriers: Discourage fast competition.

Versatile Offtake: Multiple industries with minimal reformulation needs.

For more information, check out our video

About NPCS

Niir Project Consultancy Services (NPCS) offers detailed market surveys and feasibility reports, including manufacturing processes, raw materials, plant layouts, and tailored financial models. NPCS helps entrepreneurs launch liquid paraffin or other industrial ventures with practical guidance.

Conclusion

Entering the liquid paraffin oil manufacturing sector offers strong opportunities for entrepreneurs. With a multi-billion-dollar global market growing at mid-single-digit rates, there is potential in cosmetics, pharmaceuticals, industrial, and food sectors.

Key action steps:

Define your target grades (pharma, cosmetic, etc.).

Secure dependable feedstock and refining partners.

Establish quality systems that meet global pharmacopoeia or ISO standards.

Develop a dual sales strategy for niche and bulk markets.

Differentiate via compliance, traceability, or blending capabilities.

Find the best ideas for yourself with our startup selector tools.

Frequently Asked Questions (FAQs)

Q1. What is the difference between liquid paraffin oil and mineral oil?

They are essentially the same product. “Liquid paraffin oil” is often used in pharmaceutical and cosmetic contexts, while “mineral oil” is a more general industrial term.

Q2. Is liquid paraffin safe for skin use?

Yes, pharmaceutical and cosmetic grades are purified to remove harmful components, making them safe for skin applications. Always ensure the product meets USP/BP/IP standards.

Q3. How is liquid paraffin different from paraffin wax?

Liquid paraffin is a clear, oily liquid, while paraffin wax is a solid form used in candles, coatings, and polishes. Both come from petroleum refining but differ in physical state and application.

Q4. Can startups compete with large companies in this sector?

Yes. By focusing on high-purity niches, building strong client relationships, and offering flexible supply, startups can carve out profitable segments despite large competitors.

Q5. Which industries have the highest demand for liquid paraffin oil?

Cosmetics & personal care, pharmaceuticals, food processing, industrial lubrication, and packaging are the largest consumers.