India’s growing chemical industry offers a wide range of opportunities in the areas of specialty chemicals, industrial chemicals and pharmaceutical intermediates. India is becoming a hub for global sourcing and the domestic market continues to grow. This demand is driven by sectors such as agriculture, textiles, pharmaceuticals, packaging, and construction.

Before launching a new venture or expanding an existing one, entrepreneurs and MSMEs must understand which chemicals are most in demand. This article is a comprehensive guide on the most popular chemicals in India. It also includes their applications at end-use, market trends, and a simplified overview of their chemical manufacturing process. This article is aimed at industrialists who want to make data-driven chemical decisions.

India’s Chemical Industry: Current Scenario & Growth Potential

India is a leading producer of chemicals in the world, with more than 80,000 products, including bulk chemicals, specialty chemicals, agrochemicals, and intermediates. Analysts estimate the industry’s value at approximately US$220 billion by 2024 and project it to surpass US$300 billion by 2028.

This sector has been reshaped by several growth enablers:

Demand for downstream industries like electronics, pharmaceuticals, and packaging is on the rise.

Global export potential increases due to the realignment of China+1.

India’s vision of self-reliance through Make in India, the PLI scheme and Make in India.

Import dependence on critical intermediates offers room for import substitution.

India’s ability to produce eco-compliant and high-purity chemicals is a strategic asset in global supply chains.

India’s High Demand for Chemicals: Insights

Here is a detailed look at the chemicals that are in high demand today and that Indian entrepreneurs and startups consider viable to manufacture.

Acetic Acid

Acetic acid is an industrial compound that has many uses. Produce vinyl acetate, acetic anhydride, esters, and solvents. Pharmaceutical, textile, adhesive, paint, and food industries actively use it. Manufacturers also add it to adhesives, paints, and food preservatives to enhance performance and shelf life. The packaging and construction industries are major contributors to the growing demand for VAM.

Experts expect India’s demand to reach 1.3 million metric tons by 2028, growing at a CAGR of 5.8%. Currently, imports fulfill most of this demand, but local manufacturers have a strong opportunity to fill the gap. Industries produce methanol using rhodium catalysts under high pressure and temperature.

Related: How to Start an Acetic Acid Glacial Manufacturing Business

Caustic Soda (Sodium Hydroxide)

The use of caustic soda in multiple industries is essential. This includes textiles, aluminum refinement, soaps and detergents, pulp and paper, and soaps and detergents. As a powerful alkali, it is essential in the neutralization, cleaning, and pH regulation processes of industries.

Indian manufacturers have significantly increased the country’s caustic soda capacity, and experts estimate it will reach 5 million tons by 2026 Standard manufacturing is still the chlor-alkali method, which relies on electrolysis of brine. The advancements in membrane cell technologies have increased energy efficiency and environmental performance. This makes it more appealing for entrepreneurs.

Sulfuric Acid

Fertilizer, metal processing, oil refining, and wastewater treatment industries widely use sulfuric acid as a key raw material. Manufacturers across the globe produce and consume sulfuric acid more than almost any other chemical.

The primary driver of demand in India is agriculture. Primary production is achieved by the contact process. This involves the catalytic conversion of sulfur dioxide into sulfur trioxide, followed by absorption in water. Plant design must take into account regulatory compliance for sulfur emissions and waste heat recuperation.

Ethyl Acetate

Ethyl Acetate is a solvent that evaporates quickly. The low toxicity of ethyl acetate and its sweet scent make it a good choice for food and cosmetics. India is a major player in the global ethyl-acetate market, both as a producer and an exporter.

Experts expect the demand to grow at a CAGR of over 6.5% until 2028. Manufacturers typically produce the solvent by esterifying ethanol and acetic acid using a sulfuric acid catalyst. This process is efficient and scalable, which makes it ideal for medium-sized facilities with an eye on export.

Phthalic anhydride

The phthalic acid is primarily used in the production plasticizers for flexible PVC. It also has a significant role in alkyd resins and pigments. The construction, automotive and home furnishings sectors in India are expanding. Phthalic anhydride demand is increasing.

The production of this product involves the catalytic conversion of ortho-xylene and naphthalene using vanadium pentoxide catalysts in fixed-bed reactors. Optimizing yields and cost-efficiency is all about managing reaction temperatures and recovering byproducts. India’s increasing demand for flexible packaging, wire & cable insulation and other applications is pushing this compound to the forefront.

Related: Starting a Fine Chemicals Business: Top 10 Most Demanded Specialty Chemicals

Maleic Anhydride

This chemical is essential in the production of unsaturated polymers (UPR), used in automotive parts, paints and construction panels. The chemical is also used in food acidulants and lubricant additives.

India currently imports a large amount of its maleic anhydride to meet the growing demand. This is a strong argument for local production. Maleic anhydride can be produced by oxidizing n-butane and benzene using vanadium-phosphorus as a catalyst. To ensure product quality and compliance with environmental regulations, the process requires careful attention to reactor design as well as off-gas treatment.

Sodium Silicate

Also called water glass, sodium sulfate is used in detergents and adhesives as well as refractories. It can also be found in construction materials, paper, and refractories. Also, it is used to make precipitated silica, which is used in the rubber and cosmetic industries.

The demand for sodium silicate is increasing due to its use in environmentally friendly construction materials and industrial cleaning products. The manufacturing process involves heating soda ash and silica in a high-temperature furnace or reacting the two in an autoclave under pressure using steam. It is a simple process that can be used by small and medium-scale units.

View our Handbooks on Chemical Technology (Organic, Inorganic, Industrial), Fine Chemicals

Chlorinated Paraffin Wax

The complex mixture of chlorinated paraffin is used in paints, sealants, rubber, PVC and as a flame retardant. It increases product flexibility, durability, and water resistance.

India is a major CPW exporter and producer, and the market for new players is still strong, with demand from the cable manufacturing, flooring, and insulation segments increasing. The manufacturing process is the chlorination of hydrocarbon paraffins. Liquid chlorine reacts with heavy paraffin at controlled temperatures and pressures in a closed-loop system.

Hydrogen Peroxide

Hydrogen peroxide is increasingly used as an oxidizing agent in the textile bleaching industry, paper pulp treatment and chemical synthesis. It also finds increasing use for environmental disinfection. It is a popular substitute for chlorinated agents used in the wastewater treatment and food processing industries.

The anthraquinone process, which uses a cyclic hydrogenation-oxidation of anthraquinone derivatives, is the standard production method. The shift to sustainable chemicals is expected to drive India’s market for hydrogen peroxide to grow at a CAGR of nearly 6.8%.

Formaldehyde

Formaldehyde is a key component of the furniture, MDF and plywood industries. It’s used as a building material for resins and adhesives. India’s formaldehyde demand is increasing due to the growing popularity of engineered wood products.

The process of producing methanol by dehydrogenating it using silver or mixed metal oxide catalysts is relatively simple, but requires precise temperature control. Discussions about safer alternatives and occupational safety standards could influence the technology used in future projects.

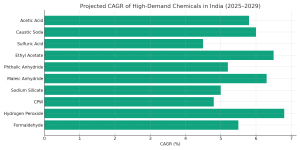

Demand Forecast Table for 2025-2029

| Chemicals | CAGR projected | Demand Expected (2029) | Key growth drivers |

|---|---|---|---|

| Acetic Acid | 5.8% | 1.3 Million Tons | VAM, packaging and coatings |

| Caustic Soda | 6.0% | 5.5 Million Tons | Textiles, alumina, detergents |

| Sulfuric acid | 4.5% | 7,8 Million Tonnes | Fertilizers and water treatment |

| Ethyl Acetate | 6.5% | 350 KT | Solvents and adhesives exports |

| Phthalic Anhydride | 5.2% | 300 KT | Paints, PVC, and automotive |

| Maleic Anhydride | 6.3% | 180 KT | UPR resins – fiberglass, lubricants |

| Sodium Silicate | 5.0% | 700 KT | Detergents, cement, and eco-construction |

| CPW | 4.8% | 500 Kt | PVC, flame retardants, cable manufacturing |

| Hydrogen Peroxide | 6.8% | 230 KT | Green oxidizers, food processing, textiles |

| Formaldehyde | 5.5% | 1.1 Million Tons | Furniture made of MDF and adhesives |

For more information, check out this video here

How NPCS helps entrepreneurs in the Chemicals Sector

Niir Project Consultancy Services (NPCS) provides critical expertise for those who are exploring chemical manufacturing opportunities.

NPCS prepares market surveys and detailed techno-economic feasibility reports for specific chemical products.

The report provides detailed information on manufacturing processes, raw materials and plant layout.

The Entrepreneurs receive professional advice to assess the commercial and technological feasibility for new chemical ventures.

Thousands of MSMEs, industrial consultants, and entrepreneurs in India have benefited from NPCS reports to launch, scale up, or optimize manufacturing businesses.

Find the Best Idea for Yourself With Our Startup Selector Tool

Conclusion

India’s chemical industry isn’t just growing, it’s also becoming more intelligent, sustainable, and globally relevant. Startups can determine their long-term success by choosing the best product based on demand data, industry sectors, and manufacturing processes that are scalable.

Entrepreneurs with the foresight to prepare themselves technically and lead the next wave in chemical manufacturing have a unique opportunity as market demands shift towards high-purity compounds and specialty products that are eco-compliant. With NPCS, you can take your idea from conception to completion in a professional manner.