Pesticides are chemical or biological substances that protect crops, livestock, and human health by controlling pests like insects, weeds, fungi, and rodents. They are essential in modern farming, improving productivity, reducing crop losses, and ensuring food security for a growing global population. The effectiveness of pesticides depends on their active ingredients and additional components that improve performance, stability, and usability. It is crucial for manufacturers, farmers, agronomists, and regulators to understand these ingredients as they influence efficacy, safety, and environmental impact.

The demand for increased agricultural output, along with limited arable land, drives the need for effective pest management solutions. However, growing concerns about environmental sustainability and human health have led to more scrutiny of pesticide ingredients. Entrepreneurs in the pesticide industry must focus on both performance and safety to stay competitive while complying with regulations. This necessity has sparked innovations in formulation science, including bio-based and safer chemical alternatives that minimize harmful residues and ecological risks.

To explore more, check our books

Active Ingredients in Pesticides

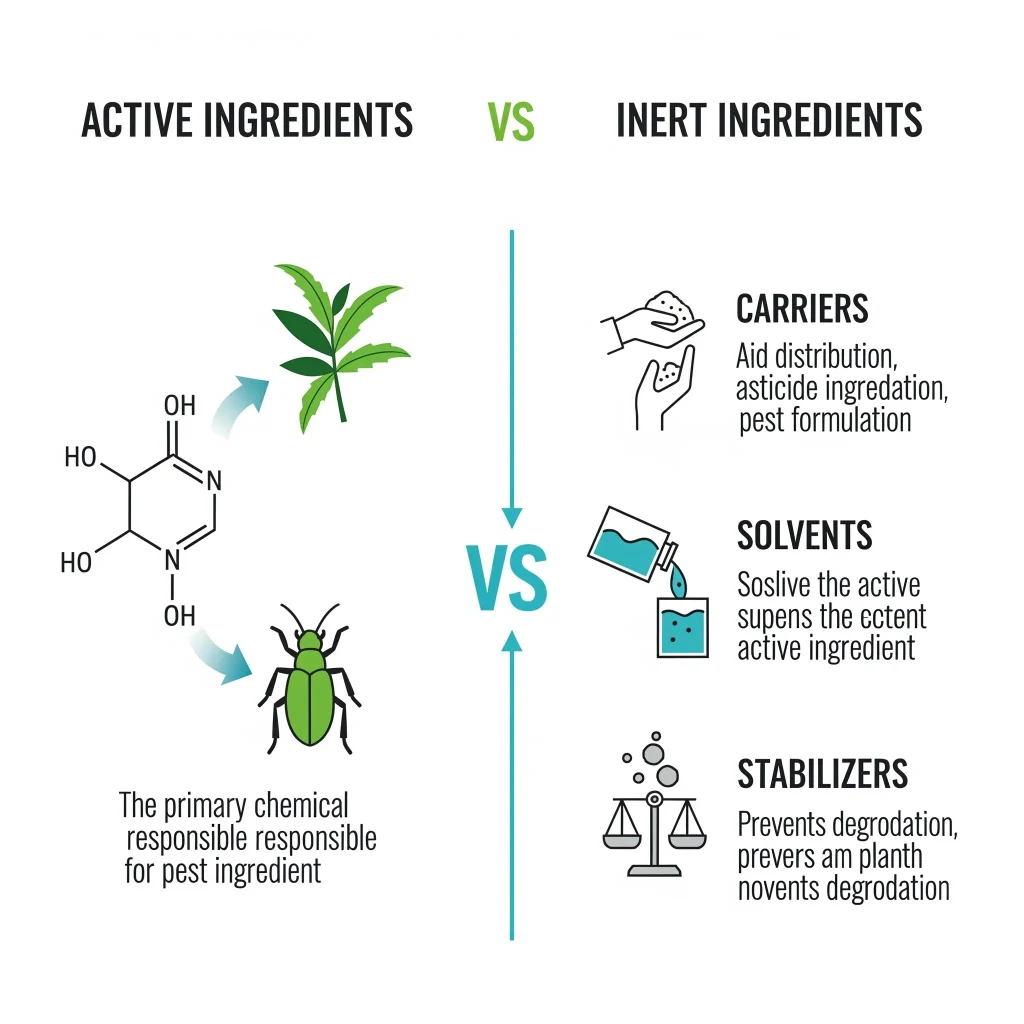

Active ingredients are the primary components of any pesticide formulation. They are responsible for controlling pests through toxicity, repellence, or disruption of biological processes. Depending on the type of pesticide and target pest, active ingredients can be synthetic chemicals or derived from natural sources.

For instance, insecticides often use organophosphates, pyrethroids, carbamates, or neonicotinoids to manage insect populations. These chemicals affect the insect’s nervous system or disrupt their reproductive cycles. Herbicides rely on compounds like glyphosate, atrazine, and 2,4-D to control weed growth, while fungicides use carbendazim, mancozeb, and copper-based compounds to prevent fungal infections in crops. Rodenticides, nematicides, and other specialized pesticides also contain active ingredients specific to their target organisms.

In recent years, biopesticides have become increasingly popular as a sustainable substitute for synthetic chemicals. These are sourced from nature, including plants, bacteria, fungi, or minerals, and often target pests in a more environmentally friendly way. For example, Bacillus thuringiensis (Bt) is a microbial insecticide widely used in agriculture to control caterpillars without harming beneficial insects. Neem oil, derived from the neem tree, acts as both an insect repellent and a growth inhibitor. The shift toward biopesticides reflects a growing preference among consumers and regulators for safer, eco-friendly pest management options.

The choice of active ingredients depends on various factors, including the target pest species, crop type, climate conditions, the application method, and regulatory approvals. Manufacturers must conduct thorough research and field trials to ensure their products provide consistent results while minimizing negative impacts on the environment, beneficial insects, and human health. Selecting effective active ingredients is essential for building a successful pesticide business.

For more information, check our project report

Inert Ingredients in Pesticides

While active ingredients control pests, inert ingredients are crucial for the overall performance and usability of pesticide products. Inert components do not have pesticidal effects but act as carriers, solvents, surfactants, emulsifiers, stabilizers, or adjuvants. They help deliver active ingredients effectively and uniformly, keep them stable during storage, and enable safe application by farmers.

For example, solvents dissolve active ingredients, making it easier to apply them as sprays, dusts, or granules. Surfactants help spread and adhere pesticide droplets to plant surfaces, improving coverage and absorption. Emulsifiers mix oil-based and water-based components for consistent application in various environmental conditions. Stabilizers protect active ingredients from degrading due to light, heat, or oxidation, resulting in a longer shelf life. Other additives can control foaming, limit evaporation, or provide color and fragrance.

Choosing inert ingredients is not random. They must work well with active ingredients and meet regulatory standards for toxicity, biodegradability, and environmental persistence. Poorly chosen inert components can undermine the pesticide’s effectiveness, create health risks for users, or leave residues in food and soil. Therefore, manufacturers carefully test and refine the entire formulation to strike a balance between effectiveness, safety, and usability.

Inert ingredients also affect the economic and operational aspects of pesticide manufacturing. Efficient formulations lower raw material costs, reduce waste, and ensure that products can be produced at scale without sacrificing quality. Entrepreneurs who grasp the role of these ingredients can create new carriers, adjuvants, and stabilizers, giving them a competitive edge.

Related articles:- Welcome to the Agrochemicals Business! Start Now Pesticides, Insecticides, Fungicides, and Herbicides Business Because Of That Fabulous In Today’s World for Its Quality

Safety and Environmental Concerns

The environmental and health effects of pesticides are closely tied to their ingredients. Active chemicals like organophosphates and neonicotinoids face scrutiny for their potential harm to pollinators, aquatic life, and humans. Some inert ingredients may also be toxic, persist in the environment, or accumulate in living organisms, raising concerns about soil and water contamination.

To tackle these issues, manufacturers are increasingly adopting safer formulations. Biopesticides, reduced-risk chemicals, and low-toxicity inert ingredients are becoming commonplace in modern agriculture. Technologies for precise application, such as targeted sprays, seed coatings, and controlled-release granules, further lessen exposure and environmental effects.

Regulatory bodies are vital in ensuring that pesticide ingredients are safe for use. Agencies like the Environmental Protection Agency (EPA) in the U.S., the Central Insecticides Board in India, and the European Chemicals Agency (ECHA) impose strict limits on active and inert ingredients, establish maximum residue levels, and require testing for safety to humans and the environment. Complying with these regulations is essential for accessing markets, export opportunities, and earning consumer trust.

Entrepreneurs must prioritize ingredient safety, invest in research and development, and adopt sustainable production practices. This approach reduces risks and aligns with global trends toward responsible agriculture. Companies that innovate with safer formulations and application methods can stand out and meet the growing demand from health- and eco-conscious consumers.

How NPCS Helps Entrepreneurs

NIIR Project Consultancy Services (NPCS) offers thorough support for entrepreneurs interested in the pesticide industry, including guidance on ingredients, formulation, and regulatory compliance. NPCS prepares detailed project reports and feasibility studies, helping businesses make informed choices about which active and inert ingredients to use and how to optimize their formulations for both effectiveness and safety.

NPCS also aids entrepreneurs in navigating complex regulatory systems, obtaining necessary certifications, and ensuring adherence to environmental, health, and safety standards. Their expertise includes sourcing raw materials, production planning, quality control, and market analysis, helping businesses lower risks and enhance operational efficiency.

For those exploring biopesticides or innovative chemical solutions, NPCS provides specialized advice on research, product development, and scaling up. By offering technical, financial, and market insights, NPCS empowers entrepreneurs to create pesticide products that meet global standards while balancing profitability and sustainability.

With NPCS’s support, new manufacturers can avoid common pitfalls like non-compliance, unstable products, or ineffective formulations. Their guidance enables entrepreneurs to focus on building a strong brand, capturing market share, and positively impacting modern agriculture.

Conclusion

The ingredients in pesticides are crucial for their effectiveness, safety, and usability. Active ingredients target pests directly, while inert components improve stability, delivery, and application efficiency. Careful selection and formulation of these ingredients are essential for creating high-quality products that meet regulatory standards and market demands.

As concerns about environmental sustainability and human health grow, the industry is gradually moving toward bio-based and reduced-risk ingredients. Innovations in formulation science, safer inert components, and precision application methods are shaping the future of pesticide manufacturing.

Entrepreneurs who focus on innovation, compliance, and responsibility can succeed in this changing sector. By prioritizing both effectiveness and safety, manufacturers can create products that support sustainable agriculture, protect ecosystems, and ensure food security. With expert guidance from organizations like NPCS, businesses can navigate regulatory challenges, optimize production processes, and establish a strong presence in the global pesticide market.

The combination of strategic ingredient selection, effective formulation techniques, and environmental responsibility makes pesticide manufacturing a promising and sustainable business opportunity for the future.

Discover the best business ideas for yourself using our startup selector tools

Frequently Asked Questions

What is the difference between an active and an inert ingredient in a pesticide?

The primary difference lies in their function. An active ingredient is the chemical compound that is responsible for killing, repelling, or controlling the pest. It is the core functional component of the pesticide. An inert ingredient, on the other hand, does not have any direct pesticidal properties. Its purpose is to help the active ingredient work better by improving the product’s consistency, stability, and ease of application.

What are some common examples of active ingredients in pesticides?

Common examples of active ingredients include various chemical compounds and biological agents. Pyrethroids are a class of synthetic insecticides that are modeled after natural pyrethrins found in chrysanthemums. Organophosphates are another group of insecticides widely used in agriculture. Carbamates are also common, working by disrupting the nervous systems of insects.

What role do inert ingredients play in a pesticide formulation?

Inert ingredients are crucial for the overall performance of a pesticide. They serve multiple purposes, such as acting as a solvent to dissolve the active ingredient, a carrier to distribute it evenly, or an emulsifier to create a stable mixture of oil-based and water-based ingredients. They can also improve the product’s shelf life, make it easier to spray, and help it stick to the surfaces of plants.

Are all pesticides made with the same ingredients?

No, pesticides are not all made with the same ingredients. The specific active and inert ingredients used depend on the target pest, the type of application (e.g., liquid spray, granular, or dust), and the environment where it will be used. A pesticide designed for a garden would have different ingredients than one used in a large agricultural field, and different active ingredients are needed to target different pests, such as insects, fungi, or weeds.

Why are some pesticides labeled as “natural” or “organic”?

Pesticides labeled as “natural” or “organic” are typically made from ingredients that are found in nature and are processed in a way that aligns with organic farming standards. These pesticides often use plant-derived active ingredients, such as neem oil or pyrethrum, or biological agents like bacteria and viruses. While they may still be toxic to pests, they are generally considered to be more environmentally friendly and less harmful to non-target species.