Coal, which is often referred to as the energy backbone of India’s sector, powers a large portion of our power stations and industrial. However, the coal mined from the earth’s crust isn’t always in a good condition to be used efficiently. It’s often filled with impurities, such as water, ash and other undesirable substances. This is when the essential process of washing coal takes place and the facilities in which this occurs are referred to as coal washeries or coal preparation facilities.

Consider a coal washery as sophisticated manufacturing facility for cleaning and sorting for coal. Similar to how you wash or prepare our vegetables before cooking them to improve the quality and flavor coal gets “washed” to improve its energy efficiency, decrease transport costs, and reduce impacts on the environment. The article below will dive into the details of the world that coal washeries play in India. We will discuss the reasons why they are important and how they operate to their full potential, as well as the huge advantages they bring to the energy landscape of India and beyond. In addition, we will examine the various kinds of washers as well as their growing significance in a country that is that is striving to improve its clean and effective energy methods.

Why Wash Coal? The Imperative Need

Raw coal, when mined is a heterogeneous mix. Along with the carbon-rich substance that is burned to generate energy, it is also a mix of unwanted components. These contaminants not only affect the effectiveness of coal combustion, but also cause a variety of environmental issues. Here’s the reason why coal washing is a crucial procedure:

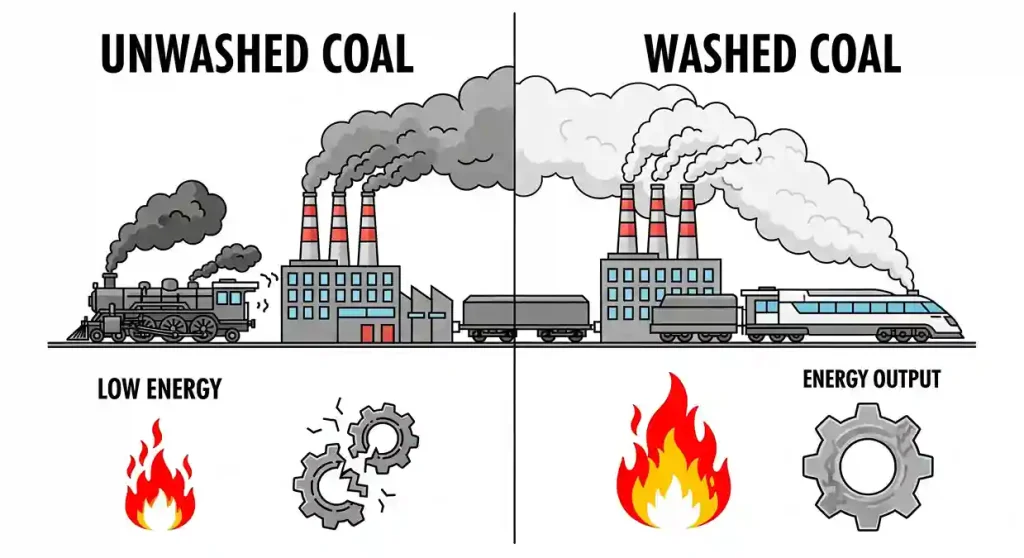

Increased Heating Value

The principal purpose of washing coal is to eliminate non-combustible substances such as ash-forming minerals. In decreasing the amount of ash and increasing heat value (the quantity of heat that is released when burning coal) for the fuel is increased substantially. This implies that power plants will need to burn less coal washed in order to produce the same amount of power which results in fuel savings.

Lower Transportation Costs

Raw coal may comprise a substantial amount of inert materials (gangue). The transportation of this weight over large distances in India is a significant increase in cost. Cleaning coal close to mines eases the burden, which makes transportation cost-effective.

Lower Emissions

The burning of coal with high ash content causes higher pollution from particulate matter (fly top ash as well as ash) and sulfur oxides (SOx) and Nitrogen oxides (NOx). Clean coal, with less impurities, results in less pollution of the air, which contributes to improved air quality within the vicinity of power stations and industrial zones.

Reduced wear and tear

The abrasive properties of the minerals that form ash in coal’s raw form can result in an increase in wear and tear on boilers as well as other equipment used in power plants. Washing coal reduces the risk of damage, resulting in less maintenance expenses and an increase in longevity of the plant.

Enhanced Coal Utilization

Some industries including that of the steel sector, demand coal that has particular quality parameters, including the low content of ash to ensure efficient production of coke. Coal washing permits making coal that comply with these strict standards.

Within the Indian context, with huge coal reserves, but typically with high levels of ash the coal washeries play an essential role in making sure that this vital resource is used effectively and without any environmental impact.

Read More: How to Start Your Own Profitable Export Business?

How Does a Coal Washery Work? The Cleaning Process

A coal washery uses the combination of chemical and physical processes to remove the important coal from undesirable substances. The exact processes employed depend on the kind of coal used, the nature of the impurities, as well as the quality that is desired of the cleaned coal. But, the majority of washing plants in India have a standard order of operations:

The coal that is mined from mines is typically composed of lumps with varying sizes. First, you need to break the lumps into a uniform size range in order to allow for efficient separation. Screens are used to separate the crushed coal into distinct size segments.

Density-Based Separation

It is at the basis of the process of washing coal. The principle behind this is the fact that coal weighs less than the majority other impurities (like rocks and shale). Different methods based on the difference in density are used:

- Jigs: The jigs make use of water that is pulsing to flow in the coal. Light coal particles travel upwards, and then are removed while heavier impurities are pushed down.

- Heavy Media Separation (HMS) or Dense Media Separation (DMS): In this method it mixes the coal with a liquid (usually an insoluble suspension of fine magnetite particle in water) The density of the fluid is managed to be in the range of coal and impurities. The coal floats in the medium and is separated from the medium, while the impurities that are denser are absorbed. HMS is especially effective in the case of coarser coal fragments.

- Hydro cyclones: They use the force of centrifugal forces in order to separate particles by their density within the slurry that swirls around coke and water. Larger particles are thrown towards the walls to slide downwards, while lighter coal particles move toward the center, and then are discharged upwards. Hydro cyclones are typically used to process smaller coal fragments.

Froth Flotation

This technique is designed for extremely small coal grains (smaller than 0.5 millimeters) which are difficult to separate with gravity-based methods. Fine coal is mixed in with water, and an agent for frothing. Air is then released across the mixture. It is then surrounded by hydrophobic (water-repelling) coal particles stick to air bubbles and ascend to the surface and form a froth which is then removed. Hydrophilic (water-attracting) impurities are left within the water.

Read Our Book: Click Here

The process of dewatering

The separation process is completed, and the cleaned coal typically takes the form of a slurry. Dewatering is vital to lower the amount of moisture. This can be accomplished by diverse methods, including:

- Screens Screens that vibrate are utilized to eliminate large amounts of water from coal that is coarser.

- Centrifuges The high-speed, rotating machines make use of centrifugal force to make it possible to separate water from finer coal particles.

- Thickeners and Filters for very thin coal slurry thickeners can be employed to help settle the solids. The coal that has been settled is then moved through filters to remove more water.

Clean Coal Handling and Storage

The dewatered coal, cleaned and soiled is transported to storage facilities ready for delivery to power plants or other industries.

Waste Handling and disposal

The impurities that are separated (rejects) are likewise handled and then transported to designated disposal areas. The use of environmentally sustainable disposal methods is crucial to reduce the effects of these wastes.

Benefits Beyond Efficiency: Environmental and Economic Advantages

Coal washeries provide a variety of advantages that go beyond improving the coal’s quality:

- Conservation of Coal Resources: By removing inert material, washeries guarantee that a greater proportion of mined coal is utilized for energy production, thus conserving this scarce natural resource.

- Reducing the amount of Ash handled and disposed Power plants that make use of washed coal produce a lot less Ash. This cuts down on the land needed for disposal of ash (ash ponds) and the cost related to transporting and handling ash. A proper management of ash is an environmental issue in India and washed coal is a great way to in reducing this.

- Water Conservation The modern coal washing plants are more and more embracing techniques for water recycling to reduce their water footprint. This is essential in a water-stressed nation like India.

- Employment Creation: The establishment and operation of coal washeries provide jobs in direct and indirect ways in the mining areas and associated industries.

- support for Cleaner Energy Technologies: Although coal is still a major fuel source improving its quality by washing helps make the combustion process cleaner and may facilitate the use of more efficient coal technology.

Read Our Project Report: Click Here

Coal Washeries in India: A Growing Landscape

India is a major source of coal reserves. It is home to an abundance of coal washeries. The majority of them located in the coal-producing states such as Jharkhand, Odisha, Chhattisgarh along with West Bengal. The washeries are run by both public sector enterprises (like Coal India Limited) as well as private companies.

The current trend in India is to increase the efficiency and capacity of the coal washing plants. This is due to the rising power demand, the stricter environmental regulations, and the economic advantages of using cleaned coal. It is also a priority on the adoption of more advanced and eco-friendly washing techniques.

Different kinds of coal washeries are able to meet particular needs:

- Coking coal washries: They are made to create high-quality, low-ash coal for the manufacturing of coke metallurgical that is vital for the steel industry.

- non-coking coal washeries: They are designed for thermal power stations and other industries that rely on coal to heat or power generation. The degree of washing as well as the desired amount of ash will vary based on the needs of the end-user.

The expansion and development of the coal washery infrastructure is vital to India to ensure security of energy.

Want To Know About Which Business Idea Would Be Better For You?

Go Through Our Startup Selector Tool

Conclusion: Brightening India’s Energy Future

Nobody talks about coal washeries, but they do the heavy lifting in India’s energy game. They clean dirty coal so it burns better, costs less, and pollutes less. These places matter.

India still runs on coal, so modern washeries are a must. They cut ash, save on transport, and lower emissions. From the mine to your home, washeries keep the lights on and help protect the air. Without them, energy in India would fall apart.

Frequently Asked Questions (FAQ)

1. What is the principal reason for a coal washery?

Coal washeries remove ash and minerals from coal. This makes the coal burn hotter, easier to transport, and less polluting.

2. What are the major methods that are involved in cleaning coal?

The main steps are crushing, sorting by density, froth flotation for fine coal, and removing extra moisture.

3. Are coal washers environmentally friendly?

The process uses water to clean coal and produces waste called rejects. Washing coal cuts down smoke, toxic gases, and ash compared to burning raw coal. New washeries recycle water and manage waste better.

4. What are the various types of coal washeries found in India ?

There are two types: coking coal washeries for steel and non-coking washeries for power plants and other industries.

5. What’s the future for the coal washing facilities in India?

Coal washeries in India are getting upgrades. They use better tech and follow stricter environmental rules. These washeries still play a key role in using India’s large coal reserves efficiently and sustainably.