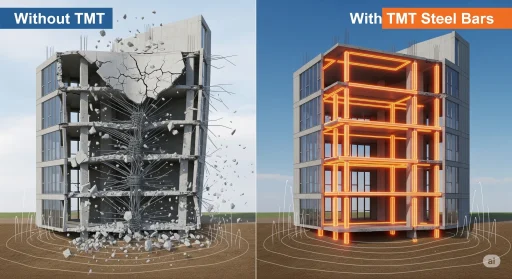

Every impressive building, imposing skyscraper, or expansive bridges start with the Skeleton. This invisible framework, hidden in the concrete, gives the structure its strength and durability. For many years, the most effective material for this crucial job has been that of the TMT steel bars. While not seen in the final construction, the rods made of high-strength steel form the core of modern construction, quietly ensuring the safety and strength of the structures that we live in and work in.

TMT means Thermo-Mechanically Treated. Basically, these bars aren’t ordinary steel rods—they’re engineered for serious strength and flexibility. Builders use them because they handle daily stress and even earthquakes without breaking a sweat. They’re the tough guys you want in any structure.

Read More: Profitable Fusion Bonded Epoxy (FBE) Coated TMT Bars Business

Here’s the deal. This article quickly breaks down TMT steel bars. How they’re made, the types you’ll find, where they work best, and why they beat out other steels. Simple, straight to the point. We will also discuss why they are now the standard for construction projects throughout India and across the globe.

What is a TMT Bar? The Unique Internal Structure

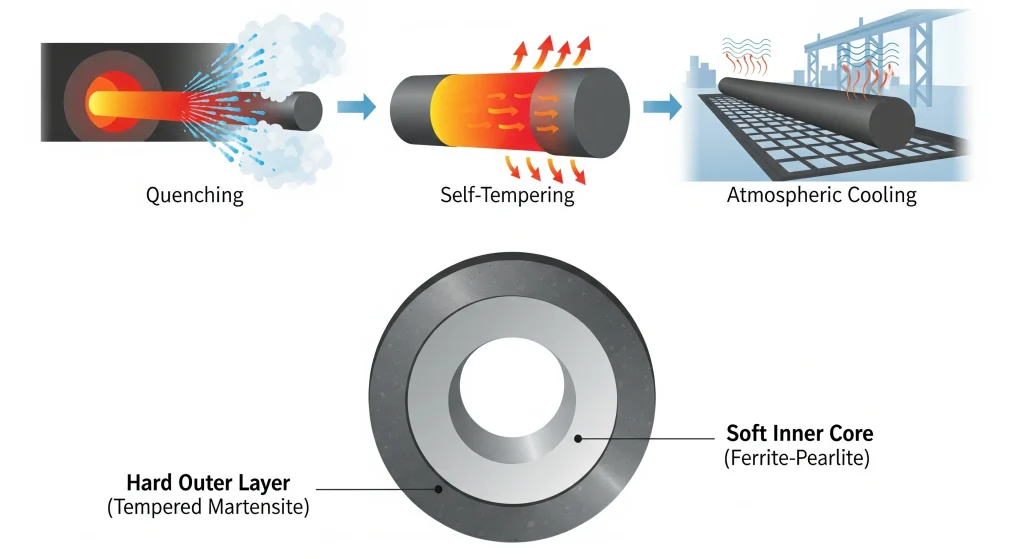

The secret behind the TMT bar’s extraordinary performance is inside its inner structure. This is a direct consequence of the process of thermo-mechanical processing. The process produces an item that has two distinct layers, each with distinct physical properties.

- The outer layer (Tempered Martensite): A tough crystal layer forms on the bar’s surface and sticks there for good. It provides the TMT bar with an enormous capacity for load-bearing and strength.

- The inner core (Ferrite-Pearlite): This is a fine, soft, and highly ductile (flexible) crystal design. Its soft and flexible core permits TMT bars TMT bar to bend or stretch without breaking, which is an essential property for earthquake resistance.

Imagine the TMT bar as bamboo stalks or a coconut. It is made of a durable outer shell, which is protected from the elements, and a soft, more flexible interior. This structure of composites makes it uniquely equipped to handle the enormous stress of modern-day construction.

The Manufacturing Process: A Three-Stage Journey of Fire and Water

The TMT bar’s two layers come from a three-step Thermo-Mechanical Treatment process.

Stage 1: Quenching starts with high-quality steel billets heated to 1100°C. Workers roll the red-hot billets into bars. Right after rolling, they blast the bars with high-pressure water. The surface cools fast and hardens into a tough martensite layer. After a brief time, the interior of the bar is still hot and still molten.

Stage 2: When the bar leaves the quenching chamber, the rapid cooling ceases. Heat from the fiery inner core moves up to the cooler, hard outer layer. This warms the surface—a process called self-tempering. This process of tempering mildly softens the martensitic layer, which increases its ductility and hardness, preventing it from becoming too hard. It’s this process that helps to refine the outer core into the perfect “tempered martensite” structure.

Stage 3: Cooling in the Atmosphere In the end, the self-tempered bars are set on a cooling bed in order to slowly cool in the air. The slow cooling process permits the soft core of the bar to change into a fine and extremely ductile ferrite pearlite crystalline structure. When the bar is completely cooled, it will have the distinctive composition of a tough solid exterior, as well as an interior that is soft and flexible.

Read Our Book: Click Here

Understanding the Grades of TMT Bars

TMT bars are classified in different grades based on the yield strengths. The yield strength refers to the highest amount of stress a bar can endure before it starts to deform permanently. The designation of grade is easy:

- “Fe” stands for Ferrous, which is the Latin word that means Iron.

- This amount (e.g., 500) is the yield strength in megapascals, or N/mm2. (MPa).

A higher number indicates that the bar is stronger. The most common types of bars available on the Indian market include:

- Fe 415 Fe 415D It was among the earliest kinds. It has less yield strength, however, it has a high degree of conductivity (flexibility). This material works great for small homes, especially in earthquake-prone areas. People in those places really trust it.

- Fe 500/Fe 500D: The most commonly used grade of Fe 500 in India, and is regarded as the standard for the market. It has a fantastic balance of strong quality and strength and is suitable for a variety of projects, ranging from private apartments and homes to commercial buildings.

- Fe 525 or Fe 550D. It is a stronger bar for large-scale infrastructure projects that require more capacity for load-bearing. It is common to find Fe 550 bars used in the construction of dams, bridges, industrial projects, as well as high-rise structures.

- Fe 600 is an extremely high-strength grade with less ductility. It is utilized in specialized heavy-duty construction such as industrial foundations, marine facilities and bridges with a high strength as the main need.

“D” or “D” in grades like Fe 500D or Fe 550D is a significant designation. It signifies that these bars have greater ductility than their counterparts without D. This makes them an ideal option for construction in earthquake-prone regions.

TMT Bar – Manufacturing Plant: Detailed Project Report

The Undeniable Advantages of TMT Bars

TMT bars are the most popular choice for reinforcements for many reasons that increase durability, safety, and value for money.

- Superior Durability and Strength: The unique manufacturing method ensures strength, which means the structure is able to withstand greater loads.

- Excellent ductility and bendability: The soft inner core permits TMT bars to bend easily into the intricate designs needed for construction, without the risk of developing cracks.

- Earthquake Resistance: A combination of strong power (outer core) and high ductility (inner core) is the primary factor in earthquake resistance. In the event of an earthquake, bars can bend and absorb an enormous quantity of force, thus preventing the structure from falling over.

- Enhanced Weldability TMT bars contain a low amount of carbon, making them very easy to weld. The joints that are welded are sturdy and don’t break down.

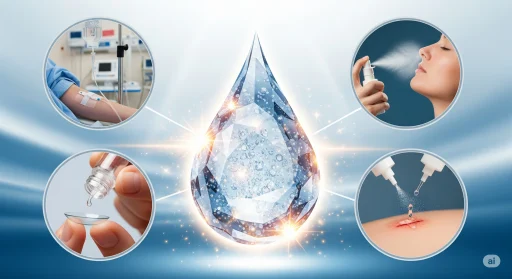

- High Corrosion Resistance The unique quenching process results in a uniform thickness on the outside, which is more resistant to corrosion and rust in comparison to earlier types made of stainless steel.

- Superior Fire Resistant: TMT bars stay strong even at crazy-high temperatures like 400-600°C. If there’s a fire, they don’t just give up—they keep things safer.

- Cost-Effectiveness Since TMT bars are more durable and more durable, engineers can create structures with less steel. This can result in lower materials, transportation, and handling expenses, making the entire project more cost-effective.

- Perfect bonding with concrete: The rib patterns on the surface of TMT bars are fabricated from the roll mills. These ribs guarantee a strong grip and bond to the concrete that surrounds them, making a strong structure.

Want To Know About Which Business Idea Would Be Better For You?

Go Through Our Startup Selector Tool

Conclusion

TMT steel bar is testimony to the strength of engineering and material science. Through a simple but effective process of cooling and heating, a common bar of steel transforms into a highly-performing material that is the perfect mix of toughness and pliability. This is a unique combination that creates it as the unsung heroes in the world of construction, securing our offices, homes, and infrastructure from the strains of time, loads, and the elements. Choosing the appropriate quality of premium TMT bar isn’t just an option for construction, it’s an investment in security, longevity and peace of mind for the generations to follow.

TMT Steel Bars: Frequently Asked Questions (FAQ)

Q1: What’s the major distinction between TMT as well as TMX bars?

TMX (Thermo-Mechanically Treated “X”) is the trademarked word for a more sophisticated variant of TMT bars. TMX bars are created by a similar method but using more advanced quenching technologies, leading to an even finer and homogeneous grain structure that may provide slightly more quality and ductility.

Q2: Are TMT bars resistant to rust?

No, TMT bars are resistant to rust; however, they are not resistant to rust. Although the manufacturing process gives them a greater resistance to corrosion than other steels, they can continue to rust even if exposed to humidity for long periods. This is the reason why proper storage on the site and providing adequate concrete covers during construction are vital.

Q3: How were bars created before TMT, and why is TMT superior?

Before TMT, CTD (Cold Twisted Deformed) bars were commonly used. They were created by twisting mild steel bars at temperatures at room temperature to improve the strength. However, this procedure created residual stresses that made the bars less brittle in addition to being less durable. TMT is a superior technique as it provides the strength and durability without sacrificing the flexibility.

Q4: What do I tell if a TMT bar is a genuine bar in the store?

Genuine TMT bars will bear the brand name and designation (e.g., Fe 500D), and they will usually have an ISI certification mark engraved on the bar regularly.

Q5: Could various kinds of TMT bars be utilized within the same project?

It is strongly recommended to use the same grade TMT bar for only one structural element. The calculations for structural designs are according to the strength of the particular grade. Mixing grades can affect the security and strength of the structure.