Solar power is the driving force behind this massive change in global energy. As they move away from fossil fuels, countries around the world are investing heavily in renewable energy. Solar energy stands out among all renewables because of its scalability and rapid cost reduction. This presents an opportunity for entrepreneurs and startups to enter the solar panel manufacturing industry. It is not only about manufacturing panels, but also about establishing yourself as a leader in a sustainable industry.

This article explores all the information an entrepreneur needs to know in order to build a profitable Solar Panel Manufacturing. It covers everything from market demand, growth trends, to technology, manufacturing processes, quality standards, and scalability.

Solar Panel Manufacturing: An Attractive Business Opportunity

Solar panel manufacturing is a rare industrial sector that combines sustainability and long-term profitability. Renewable energy is becoming a necessity, not an option. Solar is expected to make up nearly half of the new power capacity worldwide by 2030, according to the International Energy Agency. Solar is the main source of energy for the Indian government’s goal to reach 500 GW by 2030.

The industry has a high growth potential. Solar panel demand is expected to increase by 18% CAGR in the next decade. Solar panel manufacturing is becoming more attractive because of the increasing emphasis on independence. India is one of the many countries that are working to reduce their dependency on solar modules imported from abroad. This opens up a large domestic market for local producers.

Related: How to Start a Solar Panel Manufacturing Business

Understanding Market Demand and Growth Forecast

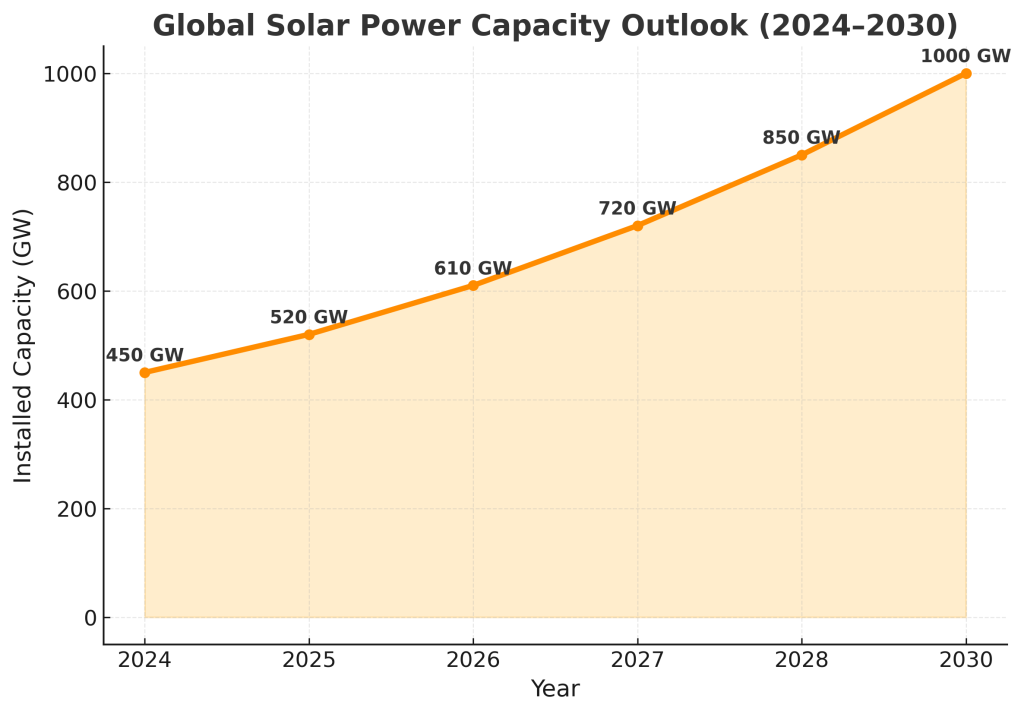

Solar panels have become an important part of the global energy transformation. Global solar power capacity will grow exponentially between 2024 and 2030. The fastest growth is expected in emerging economies such as India, Brazil and Southeast Asian countries, but mature markets including Europe and the United States will also see rapid expansion.

India’s installed capacity of solar power has already exceeded 80 GW, and ambitious targets are set to reach 280GW by 2030. To reduce dependence on imports, it is necessary not only to deploy massively but also to manufacture locally a large scale. Investment is further boosted by government incentives, such as the Production-Linked Incentive scheme (PLI) in India and similar initiatives around the world.

This translates to a constant demand pipeline for entrepreneurs. Solar panels are needed not only for large-scale utility projects, but also for rooftop installation in commercial and residential buildings, rural electrification programmes, and emerging technologies like solar-powered vehicles and appliances.

The Manufacturing Process: Transforming Technology into Tangible Products

In order to build a profitable solar panel manufacturing business, the entrepreneur needs to first understand the manufacturing process. The process is highly technical, but it can be broken down into phases. Each stage requires careful planning, appropriate equipment, and strict quality controls.

- Raw Materials– The journey starts with silicon wafers of high purity, which are the basis for most solar cells. Depending on the chosen technology, these wafers can be mono-crystalline or multi-crystalline. Mono-crystalline panels are more efficient but costlier to produce. Entrepreneurs need to decide what market segment they want to target.

- Cell Production – Silicon wafers become photovoltaic cells. Diffusion, etching and layering are the processes used to convert sunlight into electricity.

- Module assembly– The solar panels are connected, encapsulated, and protected with polymer and glass sheets. The solar cells are mounted in aluminum frames for durability and easy installation.

- Quality Control: Each panel is subjected to rigorous tests for performance, durability, and efficiency under various weather conditions. To be ready for the market, panels must comply with international standards.

Understanding these processes is crucial, as they will determine the amount of machinery to be invested in, the skills required, and the scalability of your plant. Solar panels are a long-term investment for consumers, so quality control is crucial. Successful manufacturers are distinguished by their reliability and durability.

Related: Solar Panel Manufacturing: Sunlight to Power

Selecting the Right Technology

Solar panel production is a highly profitable business. Today, entrepreneurs can choose between a variety of technologies, including monocrystalline, multicrystalline, thin-film or perovskite. Each technology has its own unique advantages, market positioning, and efficiency levels.

Monocrystalline panels are popular because they are efficient, take up less space and can be used on both residential and commercial roofs. While slightly less efficient than monocrystalline panels, polycrystalline panels are still cost-effective, and they have a large market in regions with a high price point.

The choice of technology must be in line with the market’s demand as well as the vision of the business owner for the future. Although emerging technologies are attractive, those that have been proven to work provide more stability and quicker returns at the beginning.

How to Build a Profitable Business Model

Solar panel manufacturing profitability is not only determined by production, but also by business strategy. Entrepreneurs must adopt a business model that balances efficiency, volume and differentiation.

Manufacturers often focus on larger-scale production in order to maximize economies of scale. Others, however, are more focused on niche markets like premium rooftop solutions and integrated solar roofing tiles. Manufacturers can explore B2C (Business to Consumer) models in addition to selling directly through EPC contractors. This will increase brand awareness and allow them to sell to retailers.

Service after sales, warranties and strong distribution networks are crucial to ensuring brand loyalty and repeat business. The business must remain flexible to adjust to changes in policies, tariffs and technology upgrades.

View our Handbooks on Solar Products, Renewable Energy, Solar PV Power, Solar Energy, Solar Lighting, Solar Power Plant, Solar Panel, Solar Pump, Solar Photovoltaic Cell, Solar Inverter, Solar Thermal Power Plant, Solar Farm And Solar Cell Modules

Standards of Quality and Certification

Solar panel production plants that are profitable must meet strict quality standards. International certification bodies like IEC (International Electrotechnical Commission), and regional standards such as BIS (Bureau of Indian Standards), ensure that panels comply with safety and performance requirements.

Certification is more than a formality for entrepreneurs. It is the gateway to export markets and large-scale projects. Panels cannot be sold for government or corporate projects without proper certification. These are the two main markets. It is essential to maintain quality throughout the entire production process.

Scaling Up and Future Opportunities

Solar panel manufacturing is a dynamic business. Once the plant has been operational and profitable, there are many opportunities to expand. These include manufacturing solar cells instead of wafers, manufacturing other components such as inverters or batteries, or moving towards turnkey solar solutions.

Vertical integration is a business model that can be created by integrating raw materials and solar installations. This maximizes profits and also offers resilience to supply chain fluctuations.

For more information, check out this video

How NPCS Can Help Entrepreneurs

It can be difficult to navigate the complex process of establishing a solar panel production plant. Expert consultancy can be invaluable in this situation. Niir Project Consultancy Service (NPCS) offers professional advice to entrepreneurs and startups within the industrial sector.

NPCS provides Market Study and Detailed Techno-Economic Feasibility Reports to help entrepreneurs better understand the dynamics of the market and their future venture. The reports include information on manufacturing processes, raw materials requirements, plant layouts, and financial planning. This gives a comprehensive blueprint for implementation. NPCS is a trusted partner for new businesses. It helps assess the feasibility and strength of industrial projects.

Discover the Right Business for You With Our Startup Selector Tool

Conclusion

To build a profitable manufacturing plant for solar panels, you need more than just enthusiasm for renewable energies. You also need strategic planning, technical awareness, and market insight. Global demand for clean energy and government support are driving the opportunities. Entrepreneurs can take advantage of the booming energy industry by understanding the manufacturing process and choosing the best technology. They should also adhere to strict quality standards.

With the help of organizations such as NPCS and the right consulting support, entrepreneurs can reduce risk, streamline operations, and build a venture that is profitable, but also aligned with the future of sustainable energies. Solar revolution has arrived, and those who take action today will be leaders tomorrow.