Rubber Manufacturing Business-Why to invest in this Business?

The business has both chances of going up or down. If responsive measures are taken before and during starting a manufacturing business, then there are fewer chances of loss for young entrepreneurs. For this reason, this article is for giving information on the rubber manufacturing business in India. The industrial rubber industry is witnessing growth due to its increasing application area and technological advancements in the industry.

Related Projects:- Rubber & Plastic Industries, FRP Products, Polymers, PET, PVC, LDPE, HDPE, Polypropylene, Acrylic and Polyutherthane Projects

Rubbers are some of the most adaptable materials used in almost every arena of modern industries. Engineering rubber is gradually being used in the automotive, structure & construction, an industrial trade,, wire & cable, electrical & microelectronics, bitumen change, sealant, & glue, medical & healthcare, and other submissions. The global demand for industrial rubber is projected to witness a reasonable growth of 4.6% between 2017 and 2022. The industrial rubber marketplace is expected to spread USD 33.82 billion by 2022 in terms of. The industrial rubber market is probable to observe important growth in numerous small markets, such as India, Malaysia, and Brazil.

Related Books:- Rubber Processing And Compounding Technology Books, Rubber Processing Chemicals And Leather Processing Technology Books

NPCS’s detailed project report targets to provide you with all the evaluative information required. The following are the crucial points on why to invest in this business:

- Synthetic rubber: largest type of the industrial rubber – The growth of artificial rubber can be credited to the wide use in the automotive submission as an abrasion-resistant additional for natural rubber. Synthetic rubber shaped in the latex form is used as a rubbery adhesive in carpet business. Other uses where synthetic rubber is used are drive links, conveyor belts, glues, roll coverings, and various other shaped rubber goods.

- Automotive: largest application of industrial rubber – Automotive is probable the largest use segment of the manufacturing rubber market. They possess features such as stiffness and scrape resistance, making them suitable as a supplementary for metal, glass, and wood parts used in automotive and other engineering applications. Among types of industrial rubbers, the automotive industry ingests synthetic rubber more due to its easy treating ability and better presentation.

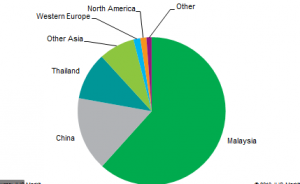

World Consumption of Rubber Latex In Different Countries

- Market Dynamics – Manufactured rubber is broadly used in the automotive industry in various uses, including gaskets, etc. The development of the automotive industry in the Asia Pacific region is mostly driven by the upsurge in automobile manufacture in China maintained by the rising title for electric vehicles. Several global corporations are investing in China and India to serve the local markets, as they will be the major and fastest-growing marketplaces in the future. Key industrial rubber producers are launching their business base in the Asia Pacific to the source to the native demand from automotive corporations. Industrial rubber engineering businesses are setting up their engineering factories in the region, as their regulars, such as Volkswagen, Benz, and other multinationals are gradually constructing automotive locally.

Related Projects:- Rubber and Rubber Products

- Opportunity: Growing demand for eco-friendly rubber –. Mainly the industrial rubber is conventionally compounded and factory-made from raw materials built on fossil fuels. To develop environment-friendly things, Europe, North America, and Japan have developed strategies that unite products to meet minimum renewable raw material content values. Industrial rubber manufacturers are developing bio-based products derived from renewable belongings and efficient by environmental regulations.

Related Vidoes:- Rubber and Rubber Products, Rubber based Industries, Natural Rubber, Synthetic Rubber, Rubber Chemicals, Extruded Rubber, Adhesives & Sealants

- Challenges Faced –Unstable raw material prices are one of the major assessments confronted by the industrial rubber market. The market for industrial rubber is very low-priced; even small changes in the supply and response balances are reproduced in its prices. The fall in crude oil prices has trapped as a major trial for the industrial rubber market,.

Raw material Cost Breakup in Rubber manufacturing Sector

| S.No. | TYPES | Cost Breakup

(%) |

| 1.) | Natural Rubber | 44 |

| 2.) | Nylon Tyre | 19 |

| 3.) | Carbon Black | 12 |

| 4.) | Rubber Chemicals | 5 |

| 5.) | Butyl Rubber | 4 |

| 6.) | Poly-Butadiene Rubber | 5 |

| 7.) | Others | 6 |

- Future Market Potential – The rubber market in the Asia Pacific is expected to grow at the highest CAGR, in terms of worth, between 2017 and 2022. The inflamed demand for industrial rubber from automotive, building & structure, manufacturing, and other uses in countries such as China and India is driving the industrial rubber market.

Concluding, rubber manufacturing is a never-ending business in India caused is also a major exporter of synthetic rubber. More than 35 percent of rubber manufactured in India is exported to middle eastern countries. So. , this report fully proves to suggest that the rubber business is a profitable one to start.NPCS’s project consultancy and marketplace research team put forward the pushing areas for rubber production business on the industrial level In India.