Hessian sacks or burlap sacks or jute gunny bags are also considered to be one of the most sustainable packaging materials in the world. As the environmental knowledge increases, demand on environmentally friendly alternatives to plastic packaging is expanding at a high pace, which puts the jute bags in the heart of a worldwide trend of sustainable packaging. To the entrepreneur and startups venturing into the industrial opportunities, jute gunny bags production presents an economically viable opportunity with an environmental relevance.

Importance of Jute in India

Along with Bangladesh, India is also among the largest producers of jute. Jute is grown in the fertile plains of the country with West Bengal, Assam, and Bihar having the best conditions to grow jute. India has a production capacity of more than 1.6 million tonnes per annum, and given that it has a local market, it offers its products to many nations. Demand has also increased by the government policies that require packaging of essential commodities such as grains and sugar in jute. This renders the theory of producing jute gunny bags not only a customary industry but also a contemporary need that is consistent with the aim of sustainability.

Raw Material Advantage

Jute is a natural fiber that is obtained as a by-product of plants called Corchorus capsularis and Corchorus olitorius. Jute is a so-called golden fiber that is abundant, biodegradable, and recyclable. Compared to synthetic materials, jute does not produce a lot of carbon and thus is environmentally friendly. It is tough and rough and resists wear and tear so it is suitable in the production of heavy duty gunny bags that are utilized in the field of agriculture, storing and transportation of food.

See our project report to find out what is happening.

Growing and Jute Processing.

Jute is grown when the weather is in the monsoon season, whereby the seeds are sown in well-drained alluvials. Jute plants grow in a short period of four to five months, and they do not demand high fertilizers and pesticides therefore they are cost effective as well as sustainable. The stalks are then harvested then retted in water bodies to soften fibers. These fibers are stripped, washed and dried. The raw jute after processing is graded and then taken to mills to be spun and woven. This raw material is a strength that enables India to have a consistent supply chain of jute bags.

Spinning and Weaving Process.

In the jute mills, fibers are carded and drawn to position them and provide strength and are then spun into yarn. The yarn is then threaded into rough cloths by the use of modern looms. The cloth is cut in sizes of choice and sewed to make gunny bags. The bags are either plain, laminated, or oiled to keep off water depending on the use. Technological advancement has made it possible to have automated processes that enhance efficiency, decrease dependence on labor, as well as ensure its uniformity.

Stitching and Finishing

The woven fabric is then made into panels, sewn with industrial machine, and hemmed/strengthened at the edges. Logos of the brand, product information or exportation signs are then printed on the bags. Other treatments can be lamination and dyeing to use in specific purposes. The constructed jute gunny bags are then loaded and shipped to wholesalers, retailers and either to industrial users directly.

To examine further, consult our books

Jute gunny bags find application in the following ways.

There are various industries where jute gunny bags are applied. In farming, they are vital in storage and transportation of grains, pulses, sugar, potatoes, onions and other farm products. Jute bags have applications in construction where they carry cement and sand. They are also used in packaging fertilizers, chemicals, and even used in geotextile to prevent soil erosion. As the environmental issue has become popular, jute bags are finding new uses in lifestyle products such as shopping packages, promotional merchandise, and fashion accessories, and this expands their market.

Environmental and Economic advantages.

Jute gunny bags have the greatest benefit in the fact that they are eco-friendly. They are 100 percent biodegradable and compostable, and thus are a good substitute to plastic bags that are banned in most countries. The cultivation of jute also makes soil fertile, and it absorbs a lot of carbon dioxide, which augments the weather equilibrium. The jute industry is also a socially responsible business venture economic wise since it provides support to millions of farmers and workers in India.

Other articles related to this one:- How to Start a Jute Bag Manufacturing Business|The Best Alternative to Plastic Bags

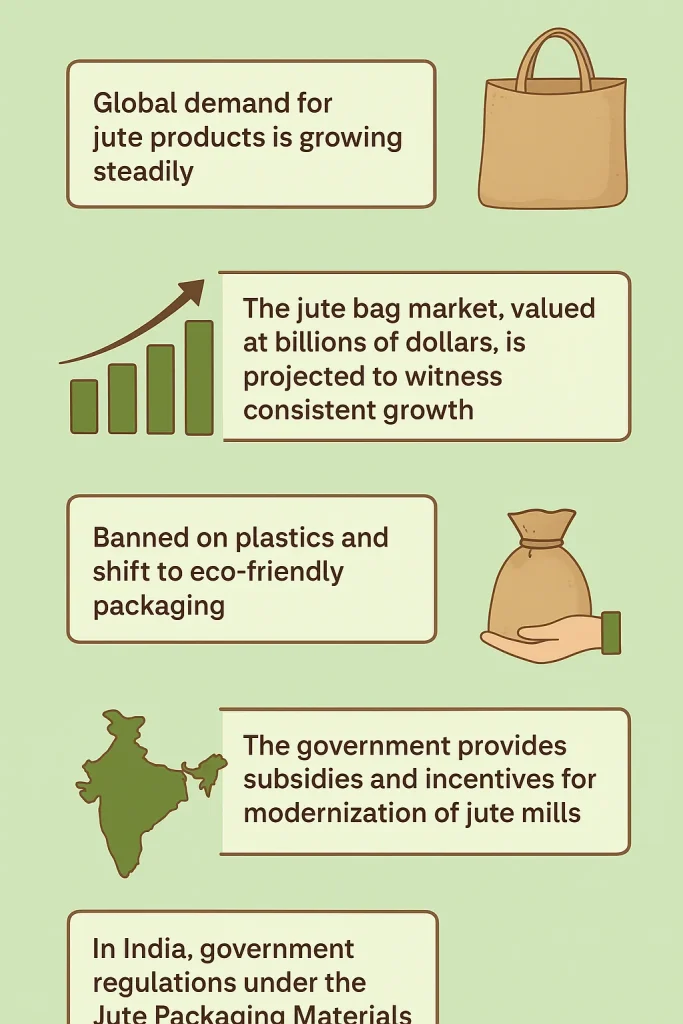

Demand in the Market and Governmental Support.

Jute products are in increased demand all over the world. Jute bag is a multi-billion dollar industry that is set to experience steady growth owing to the plastic ban and adoption of environmentally friendly packaging. In India, the Jute Packaging Materials Act legislation by the government has been obligatory that food grains and sugar be packed in jute bags which have ensured a steady domestic demand. The government also subsidizes and encourages jute mill modernization, export potential and promotion of jute-based diversified products.

Financial Outlook for Entrepreneurs

The production of jute gunny bags offers steady returns due to strong demand across industries. Export markets, particularly in Europe, the United States, and Middle Eastern countries, are increasingly turning to jute packaging due to strict environmental regulations. Startups can explore both large-scale manufacturing and niche segments like designer jute bags, which offer higher profit margins. The steady domestic market, coupled with rising global demand, makes this industry highly lucrative.

Role of Technology in Modernization

The jute industry, though traditional, has adopted significant technological advancements in recent years. Modern jute mills use automatic looms, digital printing techniques, and advanced coating methods to enhance product quality.

Challenges in the Jute Gunny Bag Industry

While the industry holds immense promise, entrepreneurs must be aware of certain challenges. The availability of water for retting during jute processing is sometimes limited, affecting fiber quality. Competition from synthetic alternatives, though declining, still poses a challenge in certain sectors due to cost differences. Fluctuations in raw jute prices also impact overall profitability. However, with strong government policies and increasing demand for eco-friendly products, these challenges can be effectively managed.

Key Considerations for Entrepreneurs

For those planning to enter the jute bag manufacturing sector, careful attention should be given to raw material procurement, quality control, and compliance with export standards. Building relationships with farmers and suppliers can ensure a steady supply of high-quality jute.

Investing in modern machinery and adopting sustainable practices can enhance competitiveness. Additionally, branding and marketing strategies emphasizing the eco-friendly nature of jute bags can attract environmentally conscious consumers both domestically and internationally.

Support from NPCS and Consultancy Services

Niir Project Consultancy Services (NPCS) provides vital support for entrepreneurs exploring opportunities in the jute bag industry. NPCS prepares Market Survey cum Detailed Techno Economic Feasibility Reports, which cover manufacturing processes, raw materials, plant layouts, and financials. Their expertise helps entrepreneurs assess the feasibility of setting up new industries, ensuring well-informed business decisions. With professional guidance, startups can navigate challenges and leverage the immense potential in the jute packaging sector.

Future Outlook

The future of jute gunny bag production is promising, with global sustainability trends driving growth. By 2030, the demand for eco-friendly packaging is expected to skyrocket, and jute will play a leading role in this transition. With continuous innovations, diversification of applications, and strong government support, jute gunny bags will remain indispensable in agriculture, industry, and lifestyle sectors. Entrepreneurs who invest in this industry today are well-positioned to capitalize on future demand while contributing to environmental conservation.

Conclusion

The production of jute gunny bags represents more than just a business opportunity; it is a step toward building a sustainable future. With India’s natural advantage in jute cultivation, government-backed policies, and rising global demand for eco-friendly alternatives, the industry offers vast potential for entrepreneurs and startups.

By adopting modern technologies, focusing on quality, and leveraging consultancy support from experts like NPCS, businesses can thrive in this sector while making a positive environmental impact.

Frequently Asked Questions

What are jute gunny bags used for?

Jute gunny bags are mainly used for packaging and transporting agricultural products such as grains, pulses, sugar, and potatoes. They are also used in cement, sand, and other bulk goods due to their strength and durability.

Why are jute bags considered eco-friendly?

Jute bags are made from natural plant fibers that are biodegradable and compostable. Unlike plastic bags, they do not pollute the environment, making them a sustainable packaging choice.

Is jute cultivation suitable only for certain regions?

Yes, jute grows best in hot and humid climates with fertile soil. India and Bangladesh are the leading producers because their climatic conditions favor jute cultivation.

What is the market potential for jute gunny bags?

The demand for eco-friendly alternatives to plastic has boosted the global market for jute bags. Governments are also promoting their use through policies banning or limiting plastic, which further increases their potential.

Can small-scale entrepreneurs enter the jute bag business?

Yes, small and medium enterprises (SMEs) can start with low to moderate investment. With the growing demand, SMEs can tap into both domestic and export markets.