The MSME steel manufacturing in India is mutually changing. Although the focus is on high-tech industry, including electronics, electric vehicles, and digital manufacturing, the oil of industrial, agricultural, infrastructure and energy ecosystem is on conventional product based on steel. In the cottages of warehouses and the fabrication yards of renewable energy, steel products are still fueling business opportunities to the MSMEs.

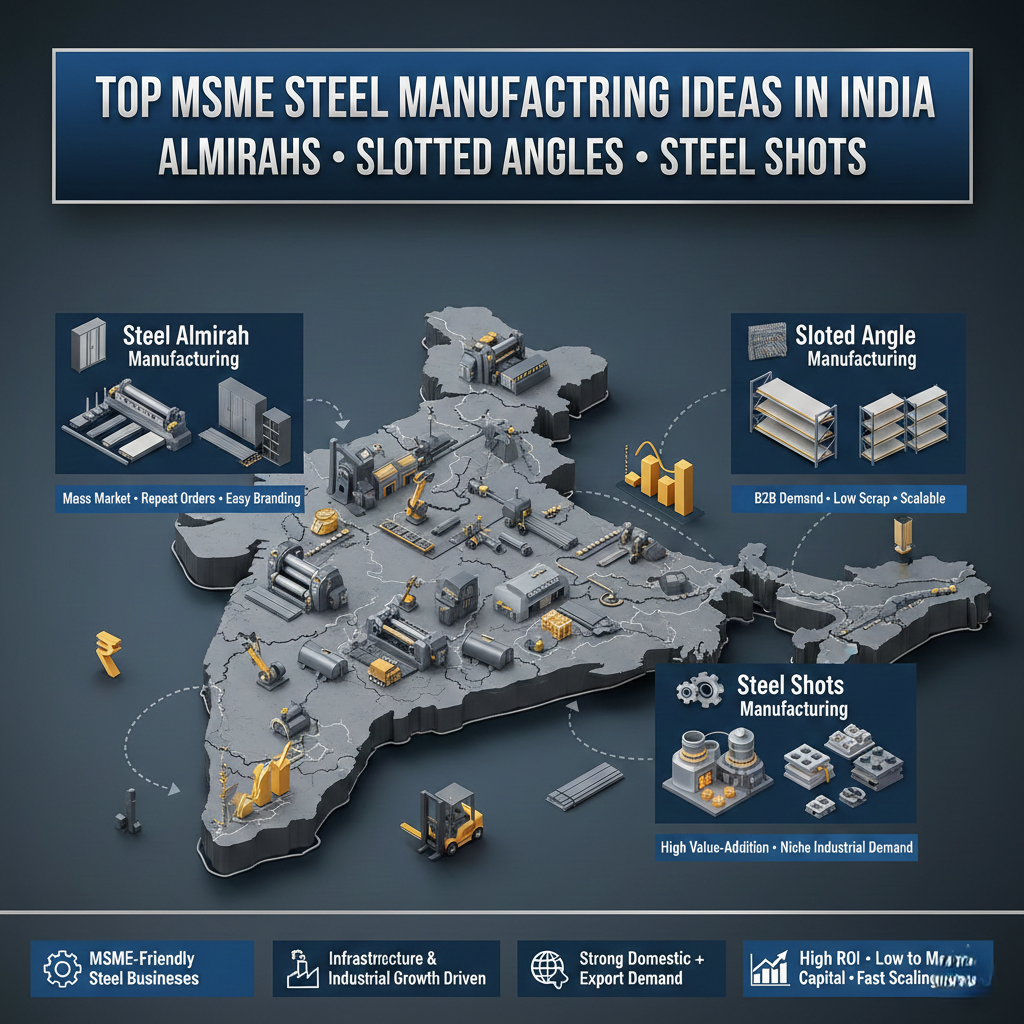

Out of the numerous opportunities, three of them can be identified as scalable, commercially viable, and allow first-generation entrepreneurs to invest in steel almirahs, slotted angles, and steel shots. The demand of these products is stable, technology can be handled and chances of high returns with disciplined operation are possible.

Read More: Mini Steel Plant with Production of Construction Bars – Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Production Schedule

Why Manufacturing based on Steel is still Relevant.

Every year, India uses more than 125 million tonnes of steel, out of which almost a third is used in value added fabricated products, as opposed to raw construction steel. Products such as storage options, industrial racks, and surface treatment abrasives play a vital role in the manufacturing of agriculture equipment, chemical plants, renewable energy projects and workshops of MSMEs.

Demand is also provided through government measures indirectly. Rural warehouse, food processing cluster programs, ethanol blending facilities, and hydrogen-ready infrastructure programs provide a regular supply of fabricated steel products.

The main advantages of the steel manufacturing to MSMEs are:

- Non-cyclical and stable demand in industries.

- Entry-level entrepreneurs have a low to medium-technological complexity.

- Potentials of expansion of small workshops to large industrial units.

Read More: 10 High-Demand Downstream Steel Product Manufacturing Ideas in India

Steel Almirah Manufacturing: Stability and Constant Returns.

Steel almirahs have come to pass outside the house and office. They are currently applied in the seed storing units, fertilizer godowns, rural banks, chemical laboratories and tool rooms in industries. The metal cabinets are safer than wooden counterparts in the fire, pests and durability.(MSME steel manufacturing in India)

The production procedure is easy and controllable and includes the processes of cutting, bending, spot welding, surface treatment, painting, and assembly. Semi- automatic CNC machines enhance the production and consistency of products without the excessive automation.

The reason why steel almirahs are lucrative:

Strong government demand (school, hospitals, rural banks)

- Strong institutional demand (schools, hospitals, rural banks).

- Constant replacement market as a result of corrosion and wear.

- Operating margins between 12–18%

- Quick breakeven than other steel products.

Read More: Manufacturing of GI Metal Sheet Products (Octagonal, Square, Rectangle Poles). Fastest Growing Industry to Start a Business with Iron and Steel.

Slotted Angles: Elasticity and Scalability.

Slotted angles are steel parts that are modular and that are utilized in creating racks and worktables, frames of solar panels, stands of agricultural equipment and shelves in warehouses. Moreover, This is due to their bolt-based construction that is flexible, and hence is needed in industrial layouts that require quick changes.

Slotted angles manufacturing is volume based and it involves roll forming, slot punching, cutting and surface finishing. Zinc or powder is added to strips made of mild steel or coils in order to prevent corrosion.

The drivers of industrial demand are:

- Warehousing and cold storage development.

- Expansion of e-commerce fulfilment facilities.

- Setups of renewable energy projects.

- The networks of agricultural inputs distribution.

As the Indian industrial storage and racking market is expanding at over 10 per cent, the slotted angle plants with the most efficient plant can have an EBITDA margin of 1522, which makes it a splendid option to scalable manufacturing.

Steel Shots: Specializing in Margins.

Steel shots consist of small metallic abrasives that are in the form of spheres and are also used in cleaning surfaces, rust removal and preparing of coats. Therefore, They cannot be allowed outside founderies, structural steel fabrication, and chemical plants, as well as the manufacture of wind turbine components.(MSME steel manufacturing in India)

It is more capital intensive to produce steel shots. Specifically, It entails high-carbon steel melting, atomization or granulation, heat treatment and classification of size. The major raw materials are scrap steel and alloying elements, and quality controls are very strict so that the hardness, roundness, and flexibility of size can be preserved.

Read More: Steel Shots/Grits – Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost and Revenue

The benefits of steel shots that is appealing to entrepreneurs:

- Frequent replacement cycles guarantee repeat orders.

- High-margin industrial product (20 30)

- High export prospects, particularly with OEM customers.

- Entry barriers diminish competition that safeguards profitability.

Indian Industrial Leaders Lessons.

Good businessmen offer good examples. Baba Kalyani of Bharat Forge began with automotive forgings and expanded into defense, energy, and heavy engineering by mastering process control and client management. Similarly, Anil Rai Gupta of Havells India illustrated how good branding and distribution and backward integration with discipline could turn manufacturing to a leading business in the market.(MSME steel manufacturing in India)

The lesson: it is better to act on the operation excellence and scale smartly afterward.

Read More: Top 20 Steel Manufacturing Business Ideas

Pro-MSME and Entrepreneur Support.

The Ministry of MSMEs has government programs to help in cluster development, access to credit, technological upgrades and guide entrepreneurship. Moreover, Consultancy firms such as Niir Project Consultancy Services (NPCS) help businessmen and women transform their ideas into functional units by guiding them in:

- Comprehensive feasibility reports of market demand and technical operations.

- Lay out of plant and choice of machinery.

- Planning of sourcing of raw material and production.

- Profitability analysis and financial projections.

This minimises the risk at the early stages and makes informed investments.

Conclusion

The manufacturing of steel is one of the most reliable industrial opportunities in India. Moreover, The almirahs made of steel are stable and can yield fast returns, the slotted angles provide scalable growth and steel shots bring in high-margin specialization. Both products are targeting various capital capacity and risk tolerance but have one significant similarity; namely, they are sustained products applicable in the agriculture, chemicals, infrastructure and energy sectors.

Moreover, Those entrepreneurs who emphasize on quality, process discipline and customer alignment will realize that these steel products offer not only factories but long and long-term manufacturing businesses.

FAQs

Is the steel production appropriate to first-generation entrepreneurs?

Yes. Such products as steel almirahs, slotted angles are technologically easy to manipulate and products with great demand in the domestic market.

What is the faster product to breakeven?

The short-term breakeven of steel almirahs is usually faster than the other product types because they require less capital and demand is stable because of institutional demand.

Is it possible to export these products?

There is also a high export potential of steel shots and slotted angles can be exported to the neighboring and developing markets.

What is the importance of automation in the first place?

Partial automation enhances quality and production whereas complete automation can be established as the production volume grows.

Which is the largest operational risk?

We address this risk through long-term relationships with suppliers and proper inventory planning.