Graphite crucibles are essential in modern metallurgy and material processing. Their ability to endure extremely high temperatures without breaking makes them crucial for smelting and refining metals. They are used for everything from aluminum to copper and precious metals to rare alloys, serving as trusted containers for melting and transforming raw materials. As industries grow and the need for new materials increases, the market for graphite crucibles has steadily expanded, creating opportunities for entrepreneurs in this manufacturing field.

Properties of Graphite

Graphite, a crystalline form of carbon, has distinct physical and chemical properties. It offers excellent thermal conductivity, resists thermal shock, and can withstand oxidizing and reducing atmospheres. These features make graphite crucibles ideal for foundries, non-ferrous metal industries, laboratories, and specialized sectors like aerospace and electronics. The potential applications for graphite crucibles are vast; with ongoing developments in material science, new uses continue to emerge. This dynamic environment makes the industry not only profitable but also sustainable over time.

Detailed project report

Understanding the Market for Graphite Crucibles

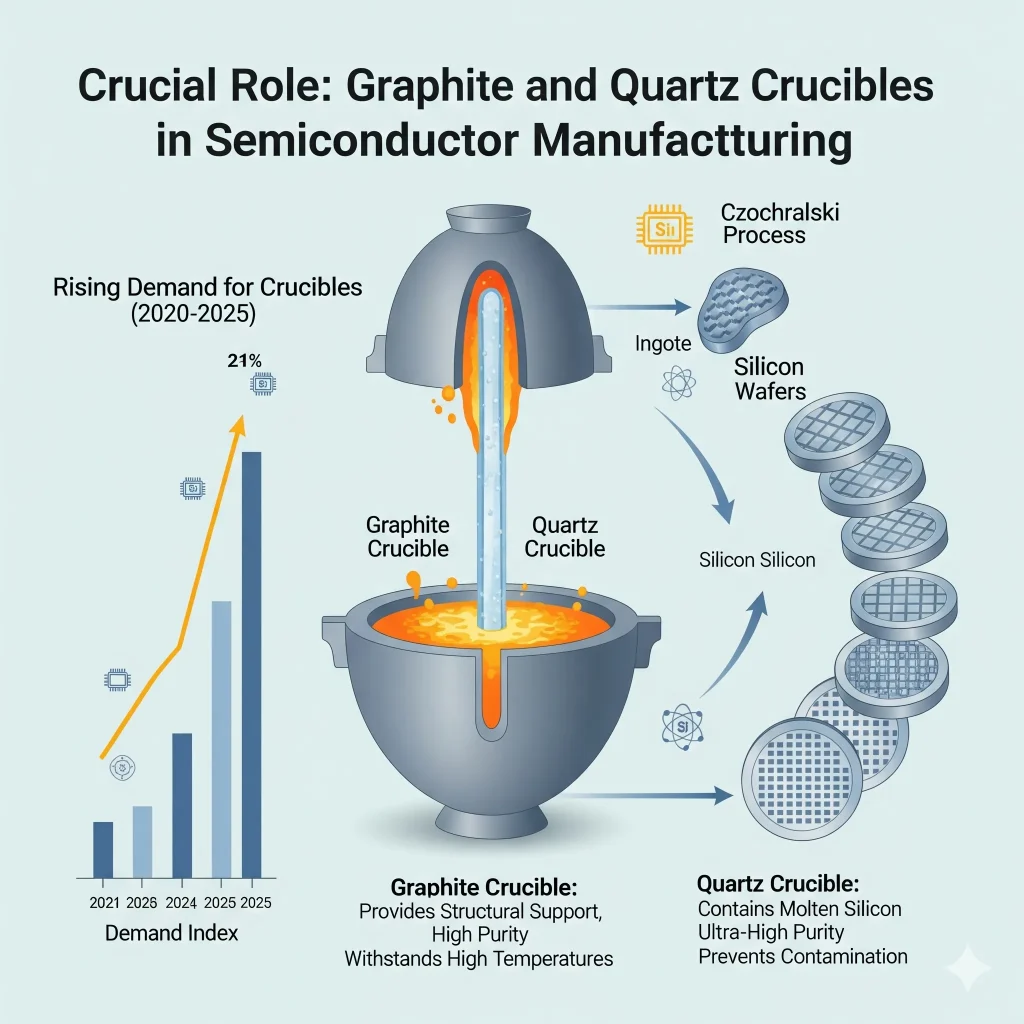

Global demand for graphite crucibles comes mainly from industries like metallurgy, foundries, chemical processing, and semiconductors. As urbanization and industrial growth accelerate in developing countries, the consumption of metals has surged. Countries such as India and China, with their growing infrastructures and automotive sectors, significantly contribute to this demand. The foundry and casting sector alone is projected to grow at an annual rate of about eight to nine percent, directly increasing the need for crucibles.

There is also a rising demand for graphite crucibles from industries focused on advanced material development. Quartz crucibles, which closely relate to graphite crucibles, play a key role in making semiconductors, especially for silicon wafers. As technology industries progress, the need for these crucibles rises. This stability makes the graphite crucible market less susceptible to short-term economic downturns and more aligned with long-term industrial growth.

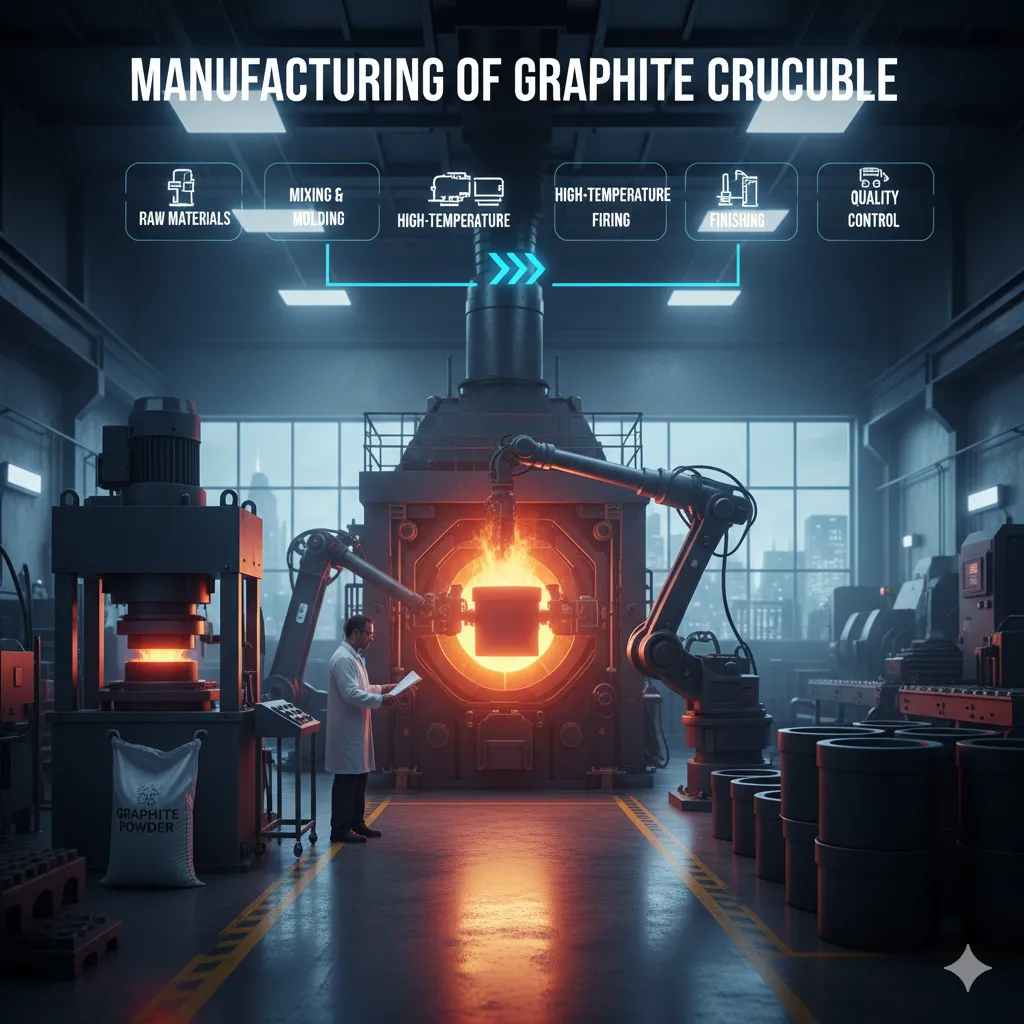

Manufacturing Process of Graphite Crucibles

The production of graphite crucibles involves several steps, starting with raw material selection. High-purity graphite is the main ingredient, mixed with binders like clay and carbon-based additives. These materials are then molded into crucibles using methods like pressing, extrusion, or isostatic molding. After shaping, the crucibles are dried, fired, and treated at high temperatures in controlled environments to improve their strength and thermal resistance.

Modern manufacturing also includes specialized coatings to boost crucible performance. For example, anti-oxidation coatings can extend the life of crucibles in reactive environments. Quality control at each stage ensures that the final product meets industry standards for durability and performance. Entrepreneurs entering this field must invest in efficient machinery, skilled workers, and strict quality assurance processes to stay competitive.

Related articles:- Investment Opportunities in Spice Powder, Gunny Bags, Graphite Crucible, Paper, N95 Masks, Sanitizer, Diaper and Sanitary Pads

Opportunities for Entrepreneurs

The graphite crucible industry presents many opportunities for entrepreneurs. Domestic demand is increasing because of growth in the metallurgical and foundry sectors, while export markets remain strong, especially where large-scale smelting operations are common. Establishing a manufacturing unit requires careful planning but can lead to steady returns once the business gains traction.

Entrepreneurs might choose to specialize in producing crucibles for specific industries like non-ferrous metals, jewelry manufacturing, or labs. Each sector has its unique needs, allowing manufacturers to build niche expertise and customer loyalty. Innovation is also crucial. By developing crucibles that last longer or perform better and cater to new applications, entrepreneurs can stand out from competitors and achieve higher profit margins.

To explore more, check our books

Challenges in Graphite Crucible Manufacturing

Despite the many opportunities, the industry faces challenges. Keeping product quality consistent is vital, as crucibles are often used in sensitive high-stakes processes. Even minor defects can result in substantial losses for users. The availability of raw materials and fluctuating costs also affect profitability. High-grade graphite often needs to be imported, exposing manufacturers to global market changes.

Competition is another issue. The industry includes both large multinational companies and smaller regional players, making it important for newcomers to identify their strengths and target markets carefully. Entrepreneurs must also comply with environmental regulations regarding emissions and waste disposal since the production process involves high temperatures.

How NPCS Helps Entrepreneurs

NIIR Project Consultancy Services (NPCS) is a reliable partner for entrepreneurs entering the graphite crucible manufacturing business. NPCS offers detailed project reports, feasibility studies, and technical advice that help simplify decision-making. Their expertise aids entrepreneurs in assessing the financial viability of projects, estimating production costs, and predicting potential revenue.

In addition to technical help, NPCS provides market analysis, allowing entrepreneurs to understand demand trends, competition, and export opportunities. Their consultants support setting up efficient production lines, choosing the right technology, and ensuring compliance with environmental and industrial standards. This reduces risks and boosts the chances of long-term success. By working with NPCS, entrepreneurs can avoid costly mistakes and concentrate on building a sustainable and profitable business.

Conclusion

Manufacturing graphite crucibles represents a promising opportunity in today’s industrial landscape. With expanding applications across metallurgy, electronics, and advanced materials, the demand for high-quality crucibles is expected to rise consistently. Entrepreneurs who focus on efficient manufacturing practices, uphold strict quality standards, and respond to changing customer needs can establish themselves as dependable suppliers in this growing sector.

While challenges exist, such as competition, raw material sourcing, and regulatory compliance, proper planning and expert guidance can help overcome these hurdles. Organizations like NPCS offer valuable support to entrepreneurs, ensuring their ventures are built on solid foundations. As industries continue to innovate and evolve, graphite crucibles will remain essential, providing a stable and profitable path for those willing to enter this field.

Discover the best business ideas for yourself using our startup selector tools

Frequently Asked Questions

What are the main steps in the manufacturing process of graphite crucibles?

The manufacturing process for graphite crucibles involves several key steps. It begins with mixing high-purity graphite powder with a binder to create a moldable compound. This mixture is then pressed into a specific mold to form the desired shape. The shaped crucible is then dried to remove all moisture and fired at an extremely high temperature in a kiln. This firing process strengthens the crucible and gives it its final properties.

What materials are used to make a graphite crucible?

A graphite crucible is primarily made from graphite powder, which is the main component. This powder is mixed with a binder, often a type of clay, to hold the shape together during the molding and firing process. Other materials, such as antioxidants or other ceramic components, may be added to improve the crucible’s durability, heat resistance, and performance for specific applications.

What industries use graphite crucibles?

Graphite crucibles are used in a variety of industries that require melting or containing materials at very high temperatures. They are widely used in foundries for melting metals like aluminum, copper, and bronze. Jewelry makers use them for melting precious metals like gold and silver. They are also essential in laboratories for high-temperature experiments and in the chemical industry for certain processes.

Why are graphite crucibles so durable at high temperatures?

Graphite crucibles are exceptionally durable at high temperatures due to the unique properties of graphite. Graphite has a very high melting point, which allows it to withstand extreme heat without deforming or melting. It also has a low thermal expansion rate, meaning it doesn’t change much in size when heated, which prevents cracking. Its chemical inertness also makes it resistant to corrosion from many molten metals.

What are the key quality checks for a manufactured graphite crucible?

The quality of a graphite crucible is crucial for its performance. Key quality checks include testing for structural integrity, which involves checking for cracks or pores that could cause failure. The dimensional accuracy is also checked to ensure the crucible fits standard furnaces and equipment. Finally, the crucible’s density and porosity are measured to ensure it can withstand repeated thermal cycles without degradation.