India’s plastic industry has become one of the fastest-growing sectors due to increased consumption in packaging, infrastructure, automotive, electronics, healthcare, and agriculture. To support this growth, the government is setting up plastic parks across the country, which serve as integrated hubs for polymer-based manufacturing. Among these, the Plastic Park at Deoghar in Jharkhand is emerging as an appealing destination for entrepreneurs and startups wanting to explore polymer processing and related fields.

Overview of Plastic Park Deoghar

Plastic Park Deoghar, under the Government of India’s Plastic Parks Scheme, promotes clusters of plastic units within industrial zones. It provides SMEs with shared infrastructure, logistics, testing facilities, and utilities.

It is strategically located in Jharkhand, known for its mineral wealth and expanding industrial base. By providing modern facilities and access to key markets, Plastic Park Deoghar seeks to attract investors and encourage innovation in the plastics sector.

Detailed project report

Benefits for Entrepreneurs

For entrepreneurs, starting units in this park reduces the burden of initial infrastructure investment and ensures long-term competitiveness. The presence of an organized cluster creates networking opportunities, enhances supply chain efficiency, and encourages collaboration with other stakeholders.

Market Demand and Growth Potential

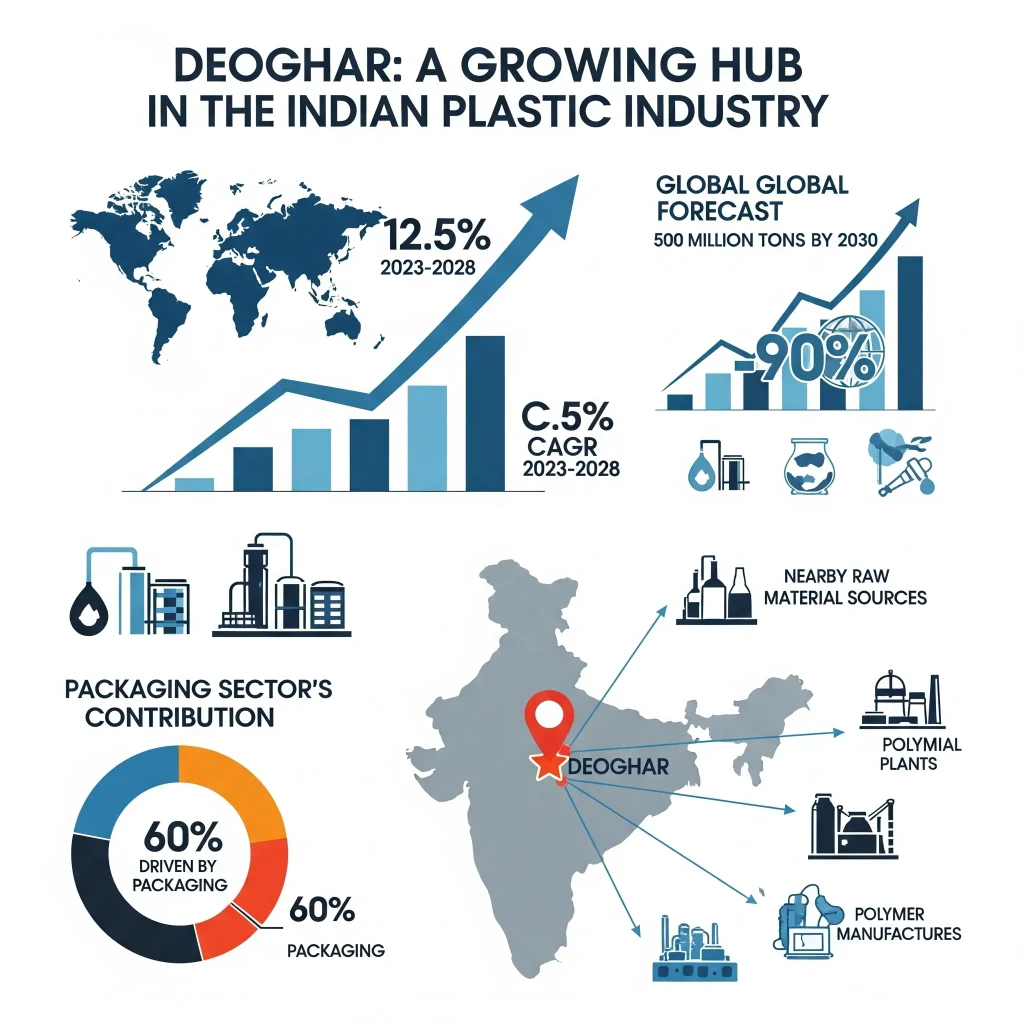

Analysts expect the Indian plastic industry to grow at a compound annual growth rate of around nine percent, with the packaging sector driving nearly sixty percent of the demand. As global demand for plastics is set to exceed six hundred million tons by 2030, India is poised to expand its share in the global market. Deoghar’s proximity to raw material sources and major industrial corridors makes it well-suited to meet both domestic and export demand.

Target Markets and Opportunities

Businesses in the park can target various markets, including packaging materials, automotive components, consumer goods, agricultural films, pipes, and medical devices. The rising demand for bioplastics and eco-friendly alternatives is also creating new opportunities for innovative entrepreneurs. With the government’s emphasis on manufacturing and ease of doing business, Plastic Park Deoghar is likely to see significant growth in the coming years.

To explore more, check our books.

Infrastructure Advantages

One of the main advantages of setting up in Plastic Park Deoghar is access to top-notch infrastructure. The park offers developed industrial plots with reliable electricity, water facilities, internal roads, and waste management systems. Shared facilities include testing laboratories, training centers, design support, and logistics services. These common resources significantly lower operational costs for entrepreneurs and enable even smaller businesses to maintain high-quality standards.

The park is well-connected by road and rail networks, allowing smooth transportation of raw materials and finished goods. Its proximity to industrial belts in Jharkhand and neighboring states offers additional business opportunities and a ready customer base.

Related articles:- Major Industries in Jharkhand Driving Economic Growth

Range of Business Opportunities

Plastic Park Deoghar provides numerous opportunities across various polymer-based industries. Entrepreneurs can set up units for manufacturing packaging films, injection-molded products, plastic furniture, automotive components, pipes, fittings, and medical disposables. The park also allows for recycling plants and eco-friendly plastic options, in line with global sustainability trends.

For startups, the cluster model provides opportunities for collaboration with established players, easy access to skilled labor, and potential for joint ventures. Export-oriented businesses will find the park particularly appealing due to its cost advantages and the government’s focus on promoting polymer exports.

Growth Drivers

Several factors are fueling growth at Plastic Park Deoghar. Increasing urbanization and rising consumer demand for packaged products are driving the need for improved plastic solutions. The automotive and electronics sectors are increasingly relying on lightweight polymer components, creating sustained demand. Moreover, agricultural modernization in India is boosting the consumption of plastic products like films, pipes, and storage solutions.

Government policies that support the plastics sector through subsidies, training programs, and tax incentives further enhance the appeal of investing in the park. Additionally, the global shift toward sourcing from cost-effective markets like India positions Deoghar as a competitive hub for both domestic and international companies.

Manufacturing Processes in the Plastic Industry

The manufacturing processes in the plastic industries vary based on the product. Common methods include injection molding, extrusion, blow molding, rotational molding, and thermoforming. Each process requires raw polymers, often supplied by large petrochemical firms. The polymers are melted, shaped, and cooled to create the desired products, with additives added to improve performance and durability.

Units in the park can utilize advanced machinery to ensure precision, efficiency, and scalability. There is also a focus on recycling technologies and biodegradable plastics to align with sustainability goals.

Challenges for Entrepreneurs

While Plastic Park Deoghar offers great opportunities, entrepreneurs must be prepared for certain challenges. Environmental concerns related to plastic waste are significant, pushing businesses to invest in sustainable practices and recycling solutions. Fluctuations in crude oil prices can affect the cost of raw polymers, impacting profitability. Additionally, competition from established players means startups need to set themselves apart through innovation, product quality, and customer service.

However, the park’s shared facilities and government support help reduce many entry barriers, making it easier for new businesses to thrive.

Role of Niir Project Consultancy Services

For entrepreneurs considering opportunities in Plastic Park Deoghar, expert guidance can be crucial. Niir Project Consultancy Services (NPCS) prepares reports that include market surveys and detailed economic feasibility studies, covering manufacturing processes, raw materials, plant layouts, and financials. These reports help entrepreneurs assess the viability of establishing units within the park and provide clear guidance for planning.

Future Outlook

The future of Plastic Park Deoghar looks bright as demand for polymer products continues to rise. With global companies seeking competitive manufacturing sites, India’s plastic parks are well-positioned to attract investment. The combination of Deoghar’s infrastructure, location advantages, and government support makes it a strategic choice for entrepreneurs.

In the next decade, the park is expected to become a center for innovative plastic solutions, eco-friendly alternatives, and businesses focused on exports. Startups that adopt sustainable technologies and leverage the park’s shared ecosystem will be well-placed in the competitive market.

Conclusion

Industrial plots at Plastic Park Deoghar offer a unique opportunity for entrepreneurs to enter one of the fastest-growing industries with strong infrastructure and government backing. The increasing demand for plastic products, along with the availability of shared facilities and access to key markets, ensures lasting viability for businesses here.

By embracing innovation, prioritizing sustainability, and utilizing expert advice, entrepreneurs can build solid ventures that contribute to local and global markets. Plastic Park Deoghar is not just a manufacturing center but also a gateway to the future of India’s plastic industry.

Discover the best business ideas for yourself using our startup selector tools

Frequently Asked Questions

What is the main objective of the Plastic Park Deoghar?

The main objective is to create a cluster-based ecosystem for the plastics industry by providing modern infrastructure and common facilities. This aims to increase competitiveness, value addition, and investment in the sector.

How many plots are available for allotment at the park?

The Plastic Park in Deoghar spans 93 acres and has a total of 107 plots available for allotment to industrial units.

Who manages the Plastic Park in Deoghar?

The park is managed by Jharkhand Plastic Park Ltd. (JPPL), which is a subsidiary of the Jharkhand Industrial Infrastructure Development Corporation Ltd. (JIIDCO).

What kind of facilities does the park offer?

The park offers state-of-the-art infrastructure and common facilities designed to support the plastics industry, which helps units move up the value chain and operate more effectively.

How can a business apply for an industrial plot in this park?

Businesses interested in a plot can contact the General Manager (Infra) of JIADA for more information. The official website of Jharkhand Plastic Park Ltd. (JPPL) also provides updates and a feedback/query section for land allotment.