Introduction

The craze for ice cream in India is not just limited to hot summer days. Over the years, it has emerged as a very profitable business, which is driven by the change in trends, better transportation facilities for cold products, and improved personal income. Entrepreneurs and business manufacturers are provided with a golden opportunity to begin an Ice Cream Franchise Business, which aids in combining the setting up of a franchise with a brand and the opportunity to run a product-based business.

Ice cream as a product is linked with the love of customers, and in the case of ice cream, where brand image is very vital to the business, it can help the business to scale fast. In this article, we aim to educate and guide MSME entrepreneurs and startups interested in the Ice Cream Franchise Business by providing the details of the market and demand, the entire manufacturing cycle, and the operation of running a franchise. Cost and investment details are not the focus in this article.

India’s Booming Ice Cream Industry: Market Demand & Growth Forecast

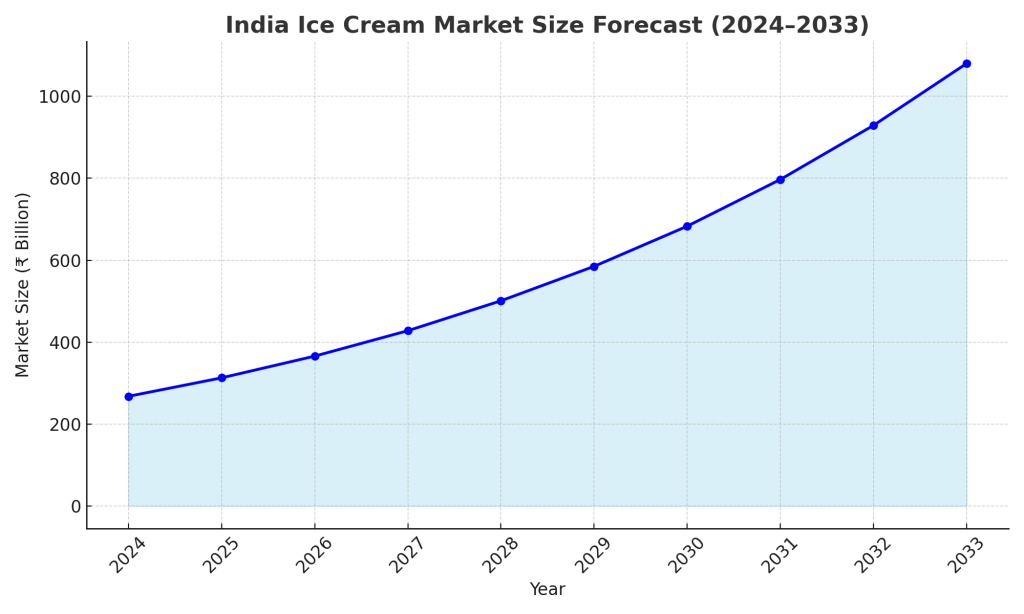

The Indian ice cream market has advanced tremendously over the past ten years, changing from a seasonal delicacy to something consumed year-round. It was estimated to be worth around ₹268 billion in 2024. It is projected to exceed ₹1,078 billion by 2033, achieving a nearly 16.7% CAGR.

This growth is fueled by several overarching trends. Increased urbanization is providing access to organized retail outlets, introducing packaged and branded food to a larger part of the population. Increased disposable incomes are shifting consumer preferences from unbranded kulfi and frozen desserts to packaged ice cream. Moreover, India’s weather is creating extended periods of high demand, including beyond the traditional summer months.

Another important growth driver is the improvement in the country’s cold chain infrastructure, which is still developing, but has seen great advancements in urban and semi-urban regions. This is crucial for frozen items, as it is now possible for franchised outlets and distributors to reach remote locations, which greatly benefits both manufacturers and franchisees.

Furthermore, the Indian market is experiencing a shift in the diversification of consumer tastes. In addition to the staples of vanilla, chocolate, and mango, there is a growing demand for artisanal, regional, vegan, low-sugar, high-protein, and fusion flavors. This sort of innovation is helping out niche micro-manufacturers and franchises who can create unique products and sell them under a parent brand’s name.

Related: 50 Successful MSME Business Ideas in India (2025 Edition)

Why Franchising is a Smart Strategy for New Business Owners

For Ice Cream Franchise Business entrepreneurs and startups, franchising offers numerous brand-related advantages. Operational readiness is one of the prominently highlighted perks as well. Franchisors offer SOPs, equipment, products, and even prescribe quality control measures. For a new business, these aids increase the likelihood of achieving consistency in taste and presentation, which is essential in this industry where purchasing is driven by sensory experience.

In addition, franchises come with brand reputation, saving years of marketing and customer acquisition efforts. Consumers tend to trust familiar names, which increases foot traffic and sales in new markets. That trust also delivers much faster break-even periods and stable revenue, especially beneficial for startups aiming to reduce early-stage volatility.

Franchisors centrally supply raw materials, flavors, and packaging in bulk at discounted rates. This streamlines quality control and minimizes input cost variability, which makes it easier for franchisees to manage profit margins. Franchisors can ease infrastructure bottlenecks by connecting franchisees with distributors, cold storage, and logistics partners.

Franchisees also benefit from brand advertising, social media, seasonal campaigns, and POS materials that would be costly and time-consuming for independents.

Manufacturing Ice Cream: A Comprehensive Guide

For entrepreneurs interested in the backend of the franchise system, like establishing an ice cream manufacturing or cold storage facility, grasping the production process is important. While parlors or kiosks sell and offer a retail experience, the backbone of quality and scalability is in manufacturing.

The formulation and selection of the best raw materials to use go first. Ingredients such as whole milk, milk powder, water, sugar, emulsifiers, and stabilizers are the most common. Depending on what the flavor will be, different natural and artificial additives such as fruit pulp, chocolate, vanilla essence, or nut pastes can be used.

To guarantee safety, all microbial activity must be eliminated. This is achieved by pasteurizing the base mixture, which binds fat and water molecules to ensure a smoother texture. Pasteurization also alleviates the need for most fat and water blending.

During the aging stage, the mixture is put through flavoring processes. After aging, the mixture is flavored. Then, air at a specific temperature is added through a continuous freezer to make the mixture light and airy. This is also the point where extra ingredients are introduced, such as cookie pieces, fruit, or chocolate chunks.

In the final step, the packaged ice cream is hardened at -25°C or below for several hours. This prevents air pockets and preserves texture during storage and shipping.

View our books on Bakery, Confectionery, Ice Cream, Chocolate and Cocoa Manufacturing

Key Operational Considerations for Franchise Manufacturers

From a manufacturing or industrial point of view, an ice cream franchise business needs more than just technical knowledge. A successful ice cream franchise needs an understanding of operational precision, process discipline, a well-planned approach to operational workflows, and customer demand forecasting.

The most critical factor for the business is hygiene. Ice cream can harbor bacteria if not handled properly. Every step from raw materials to packaging must comply with HACCP and FSSAI standards. Periodic audits, training, and documentation maintain trust and ensure compliance to industry standards.

An additional important area is ongoing temperature monitoring during storage and transportation. The cold-chain infrastructure should maintain the temperature requirements during storage, transportation, and sale. Even small deviations can result in loss of taste, texture quality, and increased wastage. Thus, monitoring systems need to comply with stringent temperature controls.

Production scheduling is important in planning strategy. Because ice cream has a short shelf life, high storage costs, and seasonal demand, production schedules must match sales forecasts. School holidays, festivals, product launches, and seasonality can all impact demand. Increased production can be achieved with flexible production capacity and with easily adjustable batching systems.

In the end, brand value that is issued with a partnership is often lost significantly due to improper quality controls. Franchise partners must follow strict formulation and packaging standards to ensure uniformity across locations. Differences in texture, flavor, or presentation can result in brand dilution and loss of consumer loyalty.

Related: Opportunities in the Industry of Flavored Ice-Cream

New Consumer Trends and Emerging Opportunities

Beyond conventional vanilla and chocolate tubs, today’s ice cream consumers are exploring an entirely new flavor and functional spectrum. Vegan and lactose-free options made from almond, soy, or coconut milk are gaining traction among health-conscious and lactose-intolerant individuals. Similarly, low-calorie and high-protein formulations are creating opportunities in the fitness and wellness markets.

Local flavors kulfi, gulkand, paan, and jaggery, are trending in urban and semi-urban areas. Regional franchises can capitalize by offering branded, standardized versions.

All these trends open doors for product innovation, marketing experimentation, and even micro-manufacturing hubs focused on specific demographics. Entrepreneurs who can align their production capabilities with these trends while maintaining franchise quality standards stand to gain significantly in the coming decade.

For more information, check out this related video

How NPCS Helps Entrepreneurs Launch Ice Cream Businesses

Niir Project Consultancy Services (NPCS) plays a vital role in helping entrepreneurs plan and launch successful manufacturing and industrial ventures. They prepare comprehensive Market Survey cum Detailed Techno-Economic Feasibility Reports, which cover everything from sector trends to profitability insights.

Their reports include deep technical coverage such as the manufacturing process, raw material sourcing, plant layout planning, and financial feasibility studies. Entrepreneurs benefit from this structured knowledge while evaluating if the business model aligns with their resources, infrastructure, and long-term goals.

Whether you’re entering the ice cream sector for the first time or expanding operations under a franchise model, NPCS provides the data, frameworks, and validation you need to make informed decisions.

Which business to start? How to choose a business idea?

Conclusion

The Indian ice cream franchise business is more than just a retail trend—it is a fast-expanding industrial sector fueled by strong consumer demand, product innovation, and supportive infrastructure. Entrepreneurs entering this space have the opportunity to combine manufacturing capabilities with brand partnerships, creating a high-margin, scalable business with year-round relevance.

By understanding the nuances of manufacturing, aligning with a trusted franchise model, and staying responsive to evolving consumer needs, startups and MSMEs can build a sustainable ice cream business that stands out in a competitive landscape. Support from expert consultants like NPCS can further strengthen your foundation, helping you move from idea to execution with confidence and clarity.