Introduction

Global food processing is changing rapidly due to urbanization and technological advancements in food. Potato powder is a versatile and in-demand product that can be used for everything from bakery products to snacks. It is a great option for entrepreneurs and startups who are considering entering the manufacturing industry. Potato powder is a great business opportunity because of its wide range of applications, steady demand, and relatively simple production process.

This guide will explore the market trends, forecasts for sector growth, the manufacturing process step-by-step, and key strategies to set up a successful business selling potato powder.

Understanding the Potato Powder Market

The potato powder is produced by grinding fresh potatoes into a fine powder after dehydrating them. It is used in many products, including soups, sauces and bakery goods. The appeal of this product is its long shelf life, ease of reconstitution and consistency in quality.

Globally, the demand for potato powder has been increasing. Growth is driven by the increasing popularity, the rapid expansion of food processing, and the strong demand for both domestic and international markets. The growth of the industry is largely driven by regions with increasing urban populations and higher disposable incomes. This includes Asia-Pacific, Africa, and other developing countries. Analysts predict that the potato powder market will grow by around 6-7% per year over the next five-year period, with export opportunities further strengthening its business case.

Why Potato Powder Is a Good Business Option

This product offers several advantages to entrepreneurs. The product is a good investment for entrepreneurs. Its raw materials are plentiful, the technology required is relatively easy compared to that of other food processing enterprises, and it has a shelf-stable quality that supports local and international sales. The versatility of the product opens up a wide range of customer segments, including snack manufacturers and bakeries, restaurants, and packaged food companies.

Related Article:- Potato Processing Sector

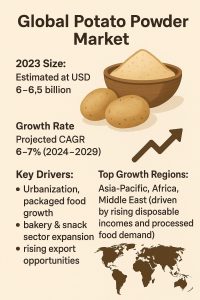

Global Potato Powder Market

2023 Size: Estimated at USD 6–6.5 billion

Growth Rate: Projected CAGR 6–7% (2024–2029)

Key Drivers: Urbanization, packaged food growth, bakery & snack sector expansion, rising export opportunities.

Top Growth Regions: Asia-Pacific, Africa, Middle East (driven by rising disposable incomes and processed food demand)

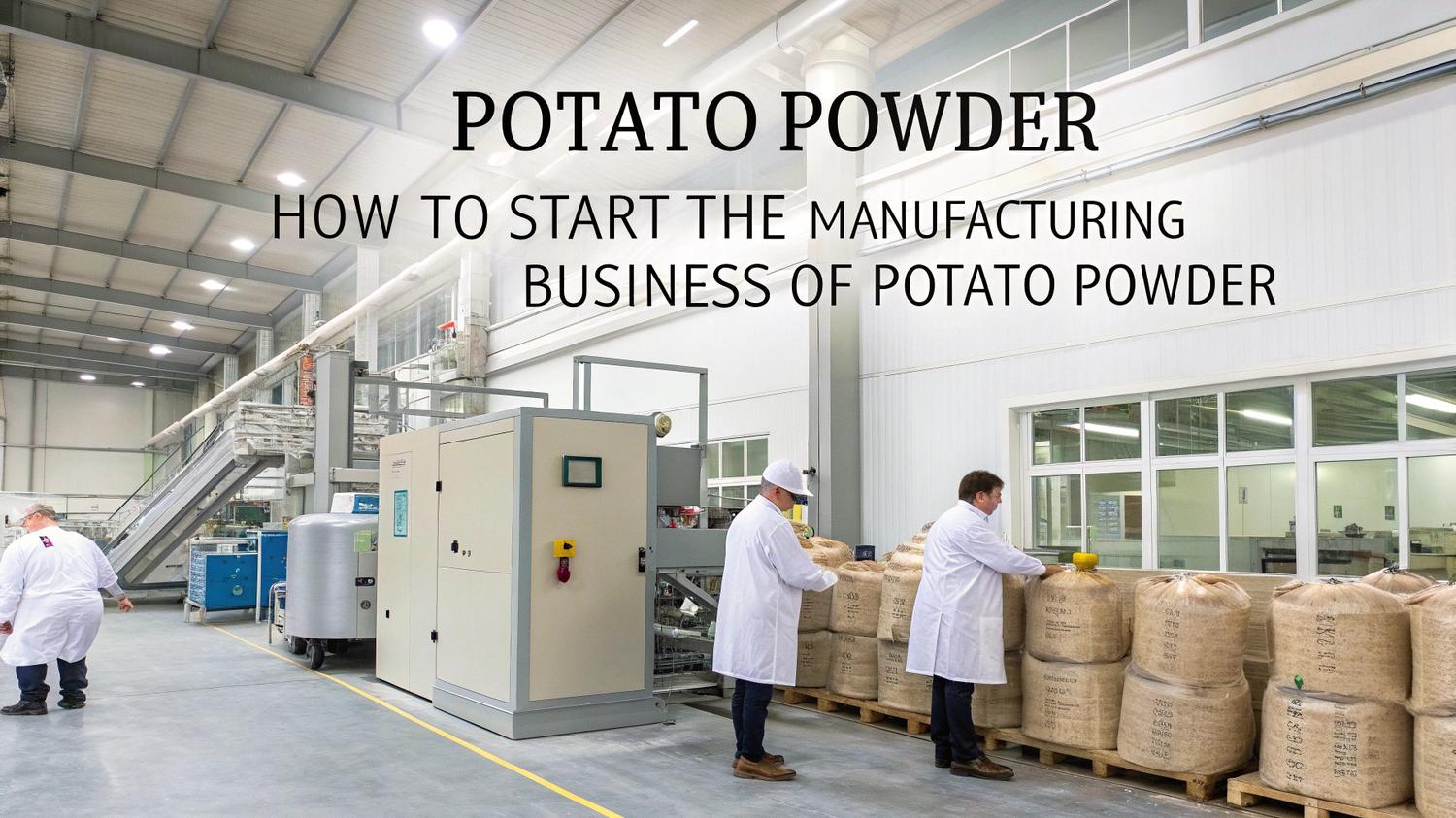

The Manufacturing Process

The basic steps of manufacturing are the same, regardless of the size or technology of the equipment.

To begin, potatoes of high quality are purchased. Those with a higher starch content produce a better yield and texture. The potatoes are cleaned thoroughly to remove dirt and debris. They are then sorted so that only healthy tubers can be used. The potatoes are then peeled (or manually, in smaller setups), and cut into equal pieces. The slices are blanched in hot water for a short time to destroy enzymes and preserve color.

The next step is drying. Using tray dryers or belt dryers (or fluidized bed dryers), reduce the moisture content to less than 6%. This will help ensure a long shelf life. The dried slices are then cooled, and the powder is ground to a fine or coarse texture, depending on the market. The powder is sieved to ensure uniform particle size. It is then packed in food-safe, moisture-proof packaging and stored under dry and cool conditions.

View Our Book:- Potato and Potato Products Cultivation, Seed Production, Manuring, Harvesting, Organic Farming, Storage and Processing

Quality & Regulatory Compliance

Safety and consistency are essential. Powder should have a natural color and smell of potato, without any microbial contamination. It is important to comply with food safety standards such as HACCP (in India), FSSAI (in the US), and FDA (in America). Regular laboratory testing ensures that the product meets domestic and export standards.

Applications for End Users

Potato powder serves many markets. It’s widely used as a flour extender for bread, cakes and cookies and instant soups, and gravies. It is a convenient ingredient that caterers and restaurants love, while food manufacturers use it because it’s affordable.

Branding and Marketing

Branding and marketing are also important for success in this industry. Entrepreneurs can make themselves stand out by emphasizing health benefits, such as gluten-free or allergen-free products, securing accreditations for credibility and using innovative packaging. Combining digital marketing with trade shows and direct outreach to the food processors will help you build a loyal clientele.

View Project Report on:- Potato Powder Manufacturing

Common challenges and how to address them

However, some of the challenges are ensuring a constant supply of high-quality potatoes, as well as implementing the correct technology and meeting requirements for storage and shelf life. To address these issues effectively, it is important to build strong relationships with farmers while also investing in training for the workforce. It is also necessary to maintain stringent storage and packaging standards.

The Role of Consulting Services

Its raw materials are plentiful, and the technology required is relatively easy compared to that of other food processing enterprises. Moreover, it has a shelf-stable quality that supports both local and international sales. In addition, the versatility of the product opens up a wide range of customer segments, ranging from snack manufacturers and bakeries to restaurants and packaged food companies.

Watch YouTube Video:- How to Set up Potato Powder Manufacturing Business

Action Plan for New Entrepreneurs

A thorough market study is the first step toward launching a successful potato powder business. Once this research is complete, the next step is to work on obtaining the necessary licenses. After that, you should focus on choosing the right technology, and finally, building a reliable supply chain of raw materials becomes the top priority. In addition, it is crucial to hire and train qualified personnel while also concentrating on rigorous quality testing. After the product is launched, you should refine both marketing and operations strategies based on customer feedback, thereby ensuring continuous improvement and long-term growth.

Conclusion

Startups that prioritize product quality, efficiency in operations, and engagement with the market can achieve significant growth. Entrepreneurs can create a niche for themselves in the growing food industry by understanding market trends, establishing solid supply chains, adhering to regulations, and leveraging expert advice from companies like NPCS. This venture can be profitable and sustainable over the long term with careful planning and execution.

Which business to start? How to choose a Business idea

How NPCS Can Help You Start and Grow a Successful Business

Niir Project Consultancy Services (NPCS) is a trusted partner for entrepreneurs, startups, and small business owners across India. With decades of experience, NPCS provides in-depth support to turn innovative ideas into scalable businesses — especially in emerging sectors like agro-waste-based manufacturing, specialty chemicals, home-based businesses, and more.

Market Research & Techno-Economic Feasibility Reports

Market Research & Techno-Economic Feasibility Reports

NPCS delivers comprehensive market research reports that include:

Industry trends and demand analysis

Legal and regulatory requirements

Raw material sourcing and local supply chain insights

Cost structure and value chain assessment

These reports help you validate your business idea and understand its viability in the real market.

FAQs: Potato Powder Manufacturing Business

What are the main uses of potato powder?

Potato powder is used in packaged snacks, instant soups, bakery goods, baby foods, gravies, and various processed foods. Its long shelf life and easy reconstitution make it ideal for both domestic consumption and exports.What certifications and licenses are required?

You will generally need food manufacturing licenses such as FSSAI registration (in India), business registration, GST, and a trade license. For export, an export license is necessary. Quality certifications like ISO or HACCP can help attract larger buyers.What are the basic steps in the manufacturing process?

The typical process involves washing and peeling potatoes, slicing and blanching them, drying to reduce moisture content, grinding into powder, sieving for uniform particle size, and finally packing in moisture-proof packaging.How important is raw material quality?

Raw material quality is crucial. Potatoes with high starch and low moisture give better yield and texture. Building long-term relationships with reliable farmers ensures a steady supply and consistent quality.

Market Research & Techno-Economic Feasibility Reports

Market Research & Techno-Economic Feasibility Reports