The rubber band business might seem rather simplistic, but it actually encompasses a diverse and lucrative segment of the overall rubber and manufacturing business. Rubber bands are widely used in the office, as well as in the home, school, farm, and workshop. They’re the heart of any diet around the world.

To understand the business of rubber bands, search that involves analysis of production, raw materials, market scenario, challenges and opportunities. This guide will break down every element, and provide actionable advice for entrepreneurs and businesses interested in breaking into the industry.

Read Our Book: Click Here

Understanding the Rubber Band Industry

Elastic bands are loops of elastic, usually ring or oval shaped, and commonly used to hold multiple objects together. They are appreciated for their ease of being bent and shaped, their durability and their cheaper than glass price. Worldwide, it is largely driven by office supplies, packaging products and organizational aids.

Even though they look like small pieces of nothing, but rubber bands need very good production techniques, QC checking and the perfect marketing and promotion so that they can reach their targeted customers.

The major categories of the industry are:

Local rubber band production: Generally operates to serve the local market, stationery shops and little pack houses. For production units, the machinery would be simple and the investment would be minimal.

Mass production: For global markets, office supply companies, and large packaging or logistics companies. These factories have automated machines to make rubber bands in mass and thus have same size, thickness, and quality.

Read More: Rubber Band Manufacturing Business

Raw Materials Used

Raw Materials The rubber production process begins with natural or synthetic rubber. Natural rubber is most favourable due to its excellent elasticity, tensile strength and durability.

Increasingly, however, synthetic rubber is also used as textile reinforcement as well, and for some compounds (specialized compounds and gum elastomers) even if it is the sole reinforcement member, other (non-textile) enhanced areas of issues still often employ other reinforcements.

Vulcanizing agents, accelerators and stabilizers can also be used as adjuvants in the manufacture. These compounds improve the elasticity, strength and heat and aging resistance of the rubber.

When the proportion of these curatives are adjusted, manufacturers may obtain rubber bands with varying properties compatible with requisite applications.

Production Process

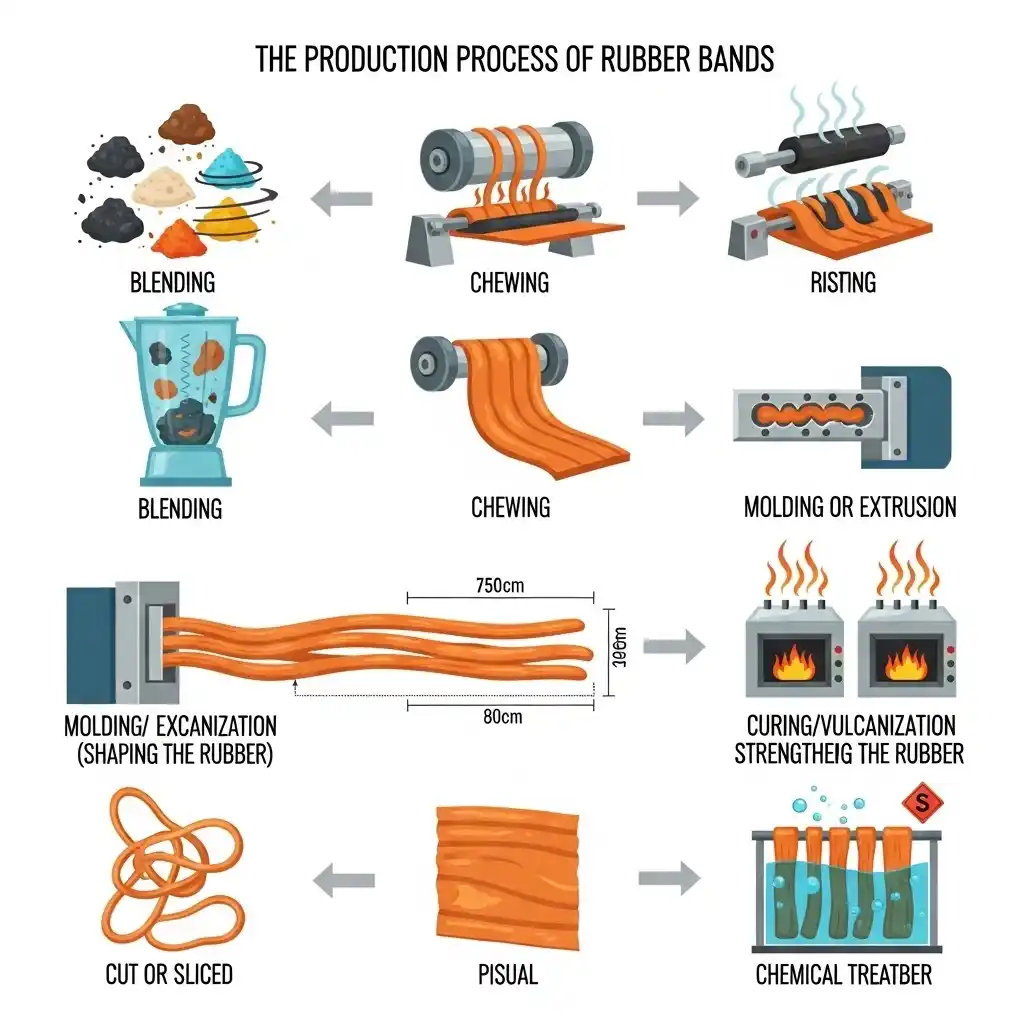

Making rubber bands is a systematic and technical process. It involves several steps:

- Blending: Raw rubber is mixed with additives in a blender or mixer. This effectively results in slave-cries and blends the ingredients uniformly, and is a first step in processing the rubber.

- Chewing: The rubber is compressed during mechanical rolling to soften it. This lower mol wt helps in extruding or forming.

- Molding or Extrusion: The type of bands to be produced determine whether the rubber is molded into tube-like rods or cut into flat strips. The dimension and thickness are precisely so dimensioned.

- Curing or Vulcanization: Heat the rubber strands with sulfur or other chemical crosslinker. This is what gives rubber its flexibility, strength, and bounce.

- Cut or Sliced: Tubular rubber is cut or sliced into cushioning loops of the desired width and thickness. It’s this step that gives the rubber band its size.

- Finishing and Quality Control: Bands are cleaned, sorted and visually inspected (for consistent thickness/serving), checked for correct foot pounds of pressure, and boxed for shipping.

Today’s factories typically utilize automated machines for each process in order to maintain uniform quality and high volumes of production.

Applications of Rubber Bands

Rubber bands are used in many different ways, so the industry withstands changes in demand:

- Office and stationery application: play papers, file groups, desks and cabinets.Colorful coding of figure,beautiful and clean.

- Agriculture: Protecting of plants, flowers and fruits during transportation.

- Packing and shipping: Keeping cartons sealed, grouped and clean and preventing dust from coming in while allowing products to breathe.

- Industrial purposes: Applied to mechanical devices, D.I.Y., and also for small machinery.

- Home Use: Used for common tasks such as sealing food packets or organizing small items.

This variety means that the rubber band never really goes out of style and the business is less risky than one that’s focused on a niche product.

Market Dynamics and Trends

The rubber bands market has been growing at a steady pace due to increasing urbanization, proliferating offices, e-commerce and industrialization. Some notable trends include:

Growing demand in emerging markets: As countries set up more offices and packaging industries, there is a greater need for rubber bands.

- Eco-friendly alternatives: Natural rubber is biodegradable and there is a growing preference for environmentally friendly products, particularly in Europe and North America.

- Custom bands: Printed rubber bands with company logos are now ordered by a number of organizations for branding and advertising.

- Integration with other items: Rubber bands are also commonly sold as part of office kits/stationery sets/packaged items.

Problems with the Rubber Band Industry

As with every industry, rubber bands have their difficulties:

- Price fluctuations of raw material: The prices of natural rubber might fluctuate bases on the climate, international trading policy or simply infected plantations.

- Competition: Barriers to enter the industry are low and there is a high level of competition, which is especially strong for local and smaller markets.

- Quality control: You want the same stretch and long-lasting fabric. Users of Substandard products can also deteriorate a company’s reputation.

- Environmental considerations: Synthetic rubber does not have the ability to naturally decompose (they are not biodegradable) and if you dispose of it improperly, it can cause the environment harm. Business will have to embrace sustainable models.

Read Our Project Report: Click Here

Starting a Rubber Band Business

These are steps entrepreneurs should take if they are interested in entering the industry:

- Market Research: Find out who your customers are offices, schools, packaging companies, or foreign markets. It’s important to understand demand, pricing and preferences.

- Situation and Layout of the Plant: The factory must be situated near the sources of raw materials, sources of electricity and facilities of transportation. Ventilation and room for machinery are other considerations.

- Investment and Equipment: Small operations need uncomplicated mixers, vulcanizers, and cutters. Zuse KG Rational large units will opt for full automatic production lines.

- Quality Control: Maintain uniform thickness, elasticity and tensile strength. Regular testing reduces product failures.

- Marketing: Sell directly to offices, retail shops and packaging companies. As the volume of online marketplaces and export opportunities increases.

Financial Planning

How to create financial balance for a rubber band business:

- Starting a Block Moulding Company: Sample Business Plan Template 3 Land, decorations, equipment, raw materials, human resources and an extra warehouse.

- Variable Costs: Oil, maintenance, packaging and wages to employees.

- Income: Based on production volume, market price and nature of rubber bands.

- Break-even Analysis: How long will it take to recoup your investment?

Contents Most entrepreneurs begin small, learn, and reinvest the profits in increasing production.

Expansion Opportunities

There are various routes for growth once a rubber band business has stabilized:

- Varied products: Create varying sizes, thicknesses and colors.

- Overseas markets: Rubber bands are imported by many countries, such as for office supply chains.

- The logo printed: Custom the rubber band with your own logo.

- Green manufacturing: Buy biodegradable or natural rubber products only to cater to green buyers.

Find the Best Idea for Yourself With our Startup Selector Tool

Conclusion

The rubber band business is not necessarily what most people think it is. Quality control Entrepreneurs who are serious about quality control can certainly set up a business that is both sustainable and scalable. Opportunities also exist for both natural and synthetic rubber, according to target markets and production cost.

Small beginnings, quality, and strategic expansion can help businesses reduce risks while increasing profits. Also, the adoption of environmentally friendly manufacturing and customization can set a brand apart in a crowded market.

In general, the rubber band business is a less risky, high demand industry with local and export sales potential. When taken care of, managed well and proper attention to details it could be a stable income and a viable business.

FAQ: Rubber Band Industry

Q1: What is investment required to start a small rubber band in business?

The initial cost of small-scale operations can be as little as a few thousand dollars to cover rudimentary machinery, raw materials and setup. There is a substantial investment in large industry scale.

Q2: How much time did it take to make the rubber bands?

Production duration depends on the machine’s speed, size of bands and quantity of production. Small-scale production can produce a batch in a couple of hours and industrial units thousands in an hour.

Q3:Are synthetic rubber bands better than natural bands?

Synthetic rubber bands are a relatively cheap and uniform product but are not as strong or as flexible as #18 yellow bands. The best one will depend on your using situation and your budget.

Q4: What are the environmental worries?

Synthetic rubber is non-biodegradable. Natural rubber is considered environmentally friendly, though responsible sourcing and waste management is essential for large-scale production.

Q5: Are rubber bands allowed to be exported?

Yes. Rubber bands are also imported for office, packaging and industrial uses in many of the countries. Exporting profits can be very high.