The golden compound, the curcumin present in saffron is increasingly attracting world consumers due to their health applications, food and cosmetics. With all who embrace natural remedies and herbal supplements, curcumin extraction is a profitable business.

Building a curcumin extraction plant needs to carefully plan, detailed steps, and robust quality controls. It’s all in this NPCS guide. All processes step by step on how to configure a curcumin extraction factory; From the choice of your materials to the market.

Read Our Book: Click Here

Why Curcumin Extraction is a Growing Industry

Curcumin is the active ingredient in turmeric, which is what makes the spice have its characteristic yellow color and healing powers. It is found in prescription drugs, over-the-counter medication, nonprescription dietary supplements and cosmetics.

With the burgeoning of Herbal supplements and clean-label product category worldwide, extracting Curcumin can be a highly profitable venture for new generation entrepreneurs.

Understanding the Basics of Curcumin

Turmeric Extracts Curcumin constitutes 2-5% of turmeric and is the largest constituent (curcuminoid compound). However, these extracts characterized as containing a great variety of things, some of them compounds. The extracted curcumin is available in various qualities: most common are:

- Powdered curcumin (capsules and tablets)

- Curcumin extract (cosmetic or food)

- Oleoresin curcumin (concentrated liquid extract)

Understanding these rules will help you decide what to make and which technology to use.

So the raw material is a best kind of turmeric rhizome. Go for varieties with a higher curcumin content. In India, Southeast Asia and some countries in Africa there are farmers who supply large quantities of turmeric.

- The turmeric must be clean, well matured and without any moulds.

- It has to be well dried or it loses all of its flavour.

- Going to the farmer directly or buying through farmers’, will save you a lot of money.

Besides turmeric, you will need food-grade solvents – usually either ethanol or acetone depending on how you ‘re extracting.

Read More: Why Curcumin Extraction is a Lucrative Business Opportunity?

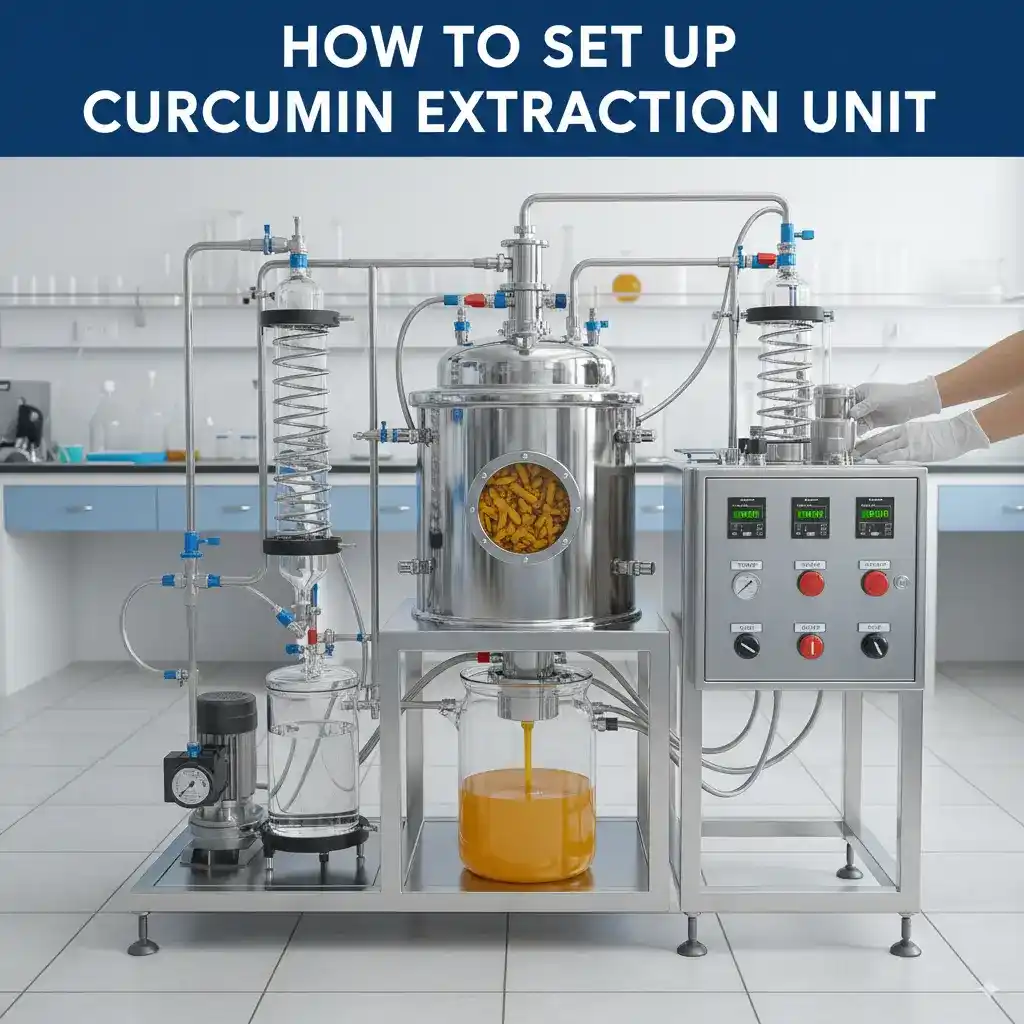

Plant Setup and Machinery for Curcumin Extraction

A curcumin extraction facility requires machines and support systems of many different kinds to operate smoothly. In addition, all of the equipment, including setups or other additions for GMP compliance, must be installed to guarantee safe quality products. All of the equipment and setups should adhere to Good Manufacturing Practices (GMP) to make sure that your product is safe and top quality.

Essential Machinery Includes:

Turmeric cleaning and polishing machine

Turmeric roots frequently carry soil, dust and sticks mixed with the ground. To remove these foreign substances, scrubbing and washing machines clean and polish the roots. This is vital in order to assure the safety of further processing of turmeric while removing of all dust.

Pulverize or grinder

After turmeric roots have been washed and dried, they need to be crushed into fine powder. A good quality pulverize or grinder can easily pulverize hard roots, faster and of very fine quality into powder or coffee bean size for extraction. A well-grounded fine powder makes extracting curcumin the easiest job.

Solvent extractor unit

Now the turmeric particles need to be moved into the solvent extraction plant. Here, special solvents do the curcumin extraction job.

Let’s be clear about this: The place to take action is here in a quality extraction plant, which yields high purity ratio and recovery of excellent extractors can offer final products be Juicier as well as better quality than any other in existence.

Distillation and recovery unit

Solvents used in extraction are not cheap or even disposable. These recovery and purification appliances clean up the solvents so that they can be used again in the next batch. Not only does recycling solvents save money for your operation, but it forces many more of their benefits to come true. The Party’s environmental impact will be better off for it as well.

Crystallizer

The liquid with curcumin and impurities therefrom is removed. In a crystallizer, the compound curcumin separates as solid crystals. This technology enhances purity by precipitating curcumin from a solution while the other compounds remain in the solution.

Dryer

There is still a small amount of moisture in the curcumin crystals or powder. The extra water is removed in dryers so that the final curcumin product will keep and not spoil.

Packaging machine

Lastly, the curcumin that is dried also needs to be packed in airtight containers. Filling, sealing and labeling are often done by machines. Right packaging that protects the curcumin and further avoids adulteration.

Auxiliary Requirements:

Clean rooms: These highly managed spaces prevent dust and germs from getting into the product.

Where to store: You’ll want separate storage for raw turmeric, processed powder, all solvents and final curcumin.

Water treatment systems: Clean, filtered water is necessary for washing and production. Treatment plants provide pure water and treatment of waste water for safe disposal.

Waste production: Solid waste and solvent residue in turmeric processing. Adequate disposal helps in maintaining the clean working environment of plant and also ensures to fulfill the required standards as per law.

With such machines and systems in place, a curcumin extraction unit can run efficiently, comply easily with safety regulations and ensure uniform output.

Read Our Project Report: Click Here

Step by Step Extraction Process

But this is just the beginning of what it takes to get the machines. For a consistent and high quality curcumin product, you need to be rigorous at each step of the extraction process. Here is a direct summary:

Step 1: Matter Preparation -Prime

Start by choosing some good turmeric rhizomes. First of all, wash them usually to remove dirt or debris. Then boil the rhizomes: this will break some of the most difficult fibers and bring a better color.

After boiling, dry them completely – this helps to avoid mold and ensure that active compounds remain intact. Rub the soil rhizomes to polish and clean any skin or impurities. Finally, in dust, this polished turmeric extracted in a fine to make it uniform in texture for better extraction.

Step 2: Solvent extraction

Now get a bottle of your saffron powder and dissolve it in food level solvents (usually ethanol or acetonitrile). The solvent dissolves the precious curcumin and nothing more.

Keep the proportion and don’t let the temperature work wild – both greatly affect the amount of curcumin you can get. This action is important because it removes the drug from inactive waste.

Step 3: filtration and concentration

Once mixed, it filters to snatch any remaining solids or impurities. You must have a clean and clean liquid when you finish this step. Then they evaporate most of the filtered solvent, warming up.

As the weak solvent, curcumin becomes increasingly concentrated, thus producing a stronger extract. This step is where purity and income are established, so small things matter.

Read More: Setting Up a Curcumin Extraction Unit: A Comprehensive Guide for Entrepreneurs

Step 4: Crystallization

When you receive the concentrated extract, quick cool in a controlled way. This cooling itself, causes the crystallization of the curcumin. The rate of cooling, the type and temperature of the solvent all appear to effect the production of crystals with acceptable optical quality.

Step 5: Drying

After the crystallization, in order to separate curcumin crystals, dry it directly from a vacuum or spray drier. Drying also removes any residual moisture, which can cause spoilage and clumping. The goal is a free-flowing powder that has the proper mouthfeel and a good shelf life.

Step 6: Packaging

Last but not least, store the dry curcumin powder immediately in an airtight container. Good packaging prevents moisture, light and other contaminants from reaching the product inside, ensuring that quality can stand the test of time.

And remember: This must all take place in a controlled environment—and with very little human touch. Each step is important if the aim is purity and reproducibility.

Find the Best Idea for Yourself With our Startup Selector Tool

Conclusion

Establishment of the curcumin extraction unit can be a profitable business if started with caution. Start with high quality raw materials, get the best equipment and perform severe quality checks.

Focus on the demands of your markets and implement sustainable methods for high value-added product options, maximizing profits.

With the increasingly high level of demand for natural health medicine, curcumin extraction is a good business opportunity in 2025 and beyond. For more assistance to launch you business in this industry, contact us.

Curcumin Extraction Unit: FAQs

Q1. What percentage of turmeric is curcumin?

Turmeric contains up to 2–5% curcumin by weight, and some 3 curcuminoid compounds have been isolated.

Q2. Is solvent extraction safe?

Yes, so long as it’s food-grade solvents and you’re getting rid of any leftover through good recovery systems.

Q3. Is it possible for small entrepreneurs to indulge into this field?

Absolutely. Smaller plants may look to local supplement markets before elongating.

Q4. Which purity grades are required?

The most prevalent commercial grade is the 95% curcumin extract for supplements and pharma.

Q5. Is curcumin extraction profitable?

Yes it can, with thorough planning & Q/C plus value added.