Milk is one of the most important food products globally, consumed daily in nearly every household. While fresh milk is a staple, its short shelf life poses storage and distribution challenges. Milk powder offers a practical solution, as it has a longer shelf life, is easy to transport, and can be used in various industries. For entrepreneurs and startups in the food and dairy sector, producing milk powder is a profitable business opportunity with rising demand both domestically and internationally.

Turning milk into powder is not a new concept, but it has gained more importance in today’s market. This shift is due to changing consumer preferences, increasing urbanization, and the growing presence of processed foods. This article discusses the business potential, production process, and market outlook for milk powder, helping aspiring entrepreneurs better understand the sector.

Understanding Milk Powder

Processors make milk powder by removing almost all the water from liquid milk through drying. This process retains the nutrients, flavor, and usefulness of milk while extending its shelf life. Consumers can easily reconstitute it by adding water, which makes it a suitable substitute for fresh milk when refrigeration or quick transportation isn’t feasible.

Different types of milk powder are available, such as whole milk powder, skimmed milk powder, and specialty powders like fortified or infant milk powder. Each type serves unique purposes in food processing, baking, confectionery, beverages, and nutrition.

Market Outlook and Growth Potential

Global Growth of the Dairy Industry

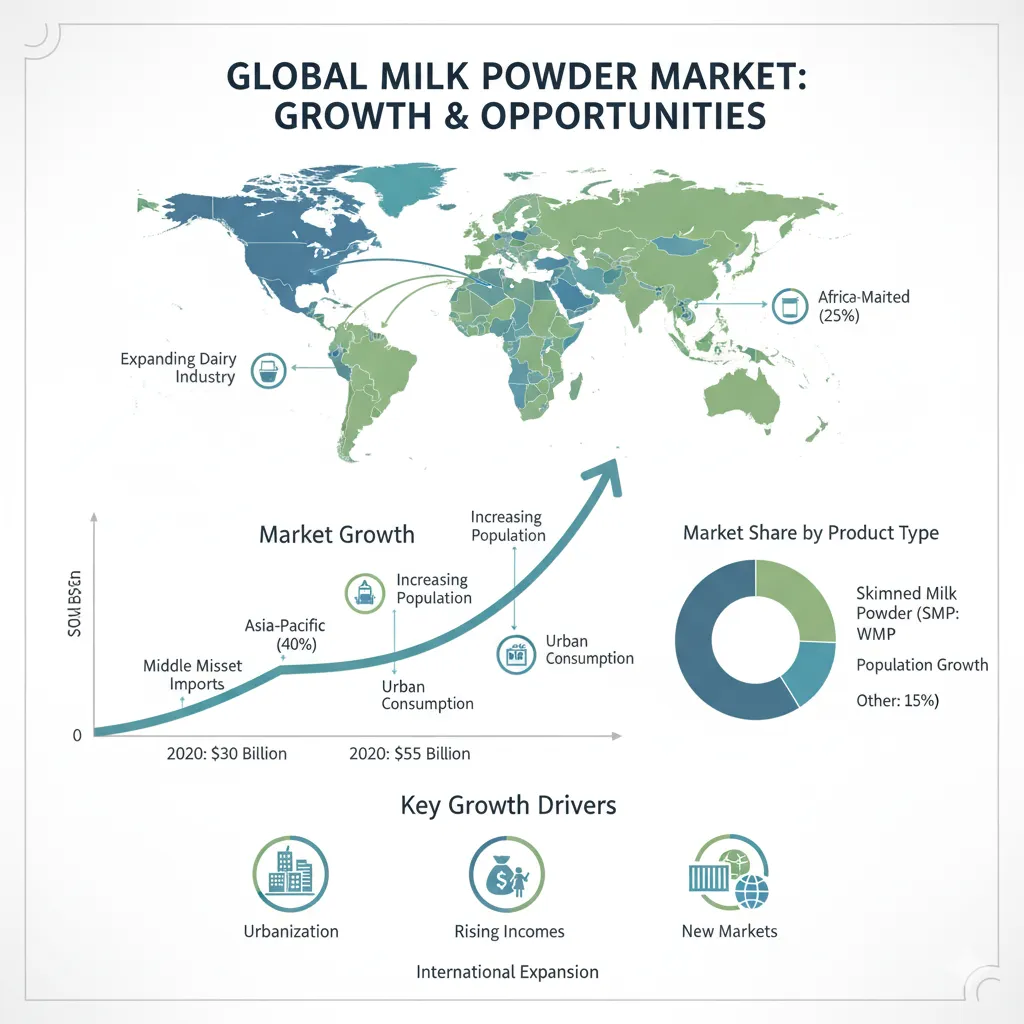

The global dairy industry has been expanding steadily, driven by increasing populations, rising incomes, and greater urban consumption. As a value-added product, milk powder benefits directly from this growth. Markets in Asia-Pacific, the Middle East, and Africa significantly depend on milk powder imports to meet domestic needs, providing producers with numerous opportunities for international expansion.

Rising Demand in Processed Foods

Milk powder is widely used in chocolates, baked goods, sweets, and ready-to-drink beverages. The growing popularity of packaged foods, instant coffee, and dietary supplements has greatly increased milk powder demand. New startups can take advantage of this trend by targeting food processing companies as their main customers.

Role of Export Markets

Countries with strong dairy production, like India, New Zealand, and European nations, are major exporters of milk powder. Emerging economies that lack sufficient dairy infrastructure rely on imports, ensuring a steady global market. Entrepreneurs looking to set up milk powder production can explore these export opportunities to fulfill unmet needs.

Forecast for the Future

The milk powder industry will grow steadily over the next decade. Developing countries will drive consumption, while rising demand for specialty milk powders like infant nutrition and fortified varieties will further boost growth. The industry will maintain a healthy annual growth rate, ensuring long-term profitability and business potential.

Detailed project report

Manufacturing Process of Milk Powder

Collection and Standardization of Milk

Farmers first collect raw milk, and processors then standardize it to achieve the desired fat and solids-not-fat (SNF) content, ensuring consistency and quality in the final product.

Pasteurization

The milk is pasteurized to eliminate harmful microorganisms and extend its shelf life. This step also helps maintain the milk’s nutritional quality.

Concentration

After pasteurization, the milk is concentrated using an evaporator, which removes about half of its water content under controlled conditions. This prepares the milk for the drying stage.

Drying Process

The concentrated milk is then transformed into powder using spray drying or roller drying methods. Spray drying is the most common technique, where hot air quickly removes any remaining water, resulting in fine milk powder particles.

Packaging

The finished powder is carefully packaged in moisture-proof containers or bags to prevent contamination and spoilage. Proper packaging is essential for maintaining product quality during storage and transport.

To explore more, check our books

Applications of Milk Powder

Food and Beverage Industry

Milk powder is a crucial ingredient in sweets, ice creams, chocolates, baked goods, and instant drinks. Its versatility makes it essential in the packaged food market.

Infant Nutrition

Specialized milk powders are formulated for infant formula, ensuring balanced nutrition for babies. This segment is rapidly growing and presents valuable opportunities for entrepreneurs.

Household Consumption

In areas where fresh milk supply is uncertain, households often rely on milk powder for daily use. Its easy storage and long shelf life make it a popular choice.

Industrial Applications

Milk powder is also used in pharmaceuticals, dietary supplements, and cosmetic formulations, showing its broad market appeal.

Related articles:- From Cow to Powder – Unraveling Milk Powder’s Simple Magic

Competitive Advantages of Milk Powder

Longer Shelf Life

Unlike liquid milk, milk powder can be stored for months at room temperature, making it ideal for regions with limited refrigeration capacity.

Easy Transportation

Milk powder is lightweight and compact compared to liquid milk, lowering logistical costs and facilitating international trade.

Nutritional Value

The drying process retains most of the essential nutrients in milk, so consumers receive similar benefits as they would from fresh milk.

Cost-Effectiveness for Industries

Food producers favor milk powder because it offers consistency, ease of use, and lower storage expenses. This reliability makes it a preferred material for large-scale operations.

Challenges in the Industry

Raw Material Dependency

The availability and quality of fresh milk are vital for this industry. Seasonal changes in milk production can disrupt the supply chain and impact profitability.

Strict Quality Standards

Since milk powder is widely consumed by children and families, meeting rigorous food safety regulations is essential. New businesses may find it challenging to adhere to these standards.

Market Competition

Numerous established global players operate in the milk powder sector, leading to stiff competition. Startups should concentrate on niche products, innovation, and branding to differentiate themselves.

Market Forecast and Future Opportunities

Innovation and sustainability will shape the future of milk powder production. Consumers increasingly prefer fortified milk powders with added vitamins and minerals as they become more health-conscious. Emerging markets will drive significant growth in infant nutrition and specialty powders.

Export opportunities will continue to expand as more countries rely on imports for their dairy needs. Entrepreneurs who create strong supply chains and uphold high-quality standards can take advantage of this trend.

Sustainable production methods, such as energy-efficient drying techniques and eco-friendly packaging, are also becoming key differentiators in the market. Companies adopting these practices can boost their competitiveness while positively impacting the environment.

Role of Niir Project Consultancy Services (NPCS)

Niir Project Consultancy Services (NPCS) assists entrepreneurs by preparing detailed market surveys and techno-economic feasibility reports. These reports address essential elements such as the manufacturing process, raw materials, plant layout, and financial projections. NPCS helps business owners evaluate the feasibility of starting new industries, including milk powder production, providing a strong foundation for informed decision-making.

Conclusion

Producing milk powder is a promising business opportunity with significant potential in both domestic and international markets. Its role in food processing, nutrition, and everyday use ensures steady demand. Although challenges exist, such as maintaining quality and competition, this sector offers long-term stability and profitability for entrepreneurs willing to maintain high standards and seek innovation.

By understanding the manufacturing process, market trends, and applications, startups can position themselves effectively in this growing field. With careful planning and execution, milk powder production can become a sustainable and rewarding business venture.

Discover the best business ideas for yourself using our startup selector tools.

Frequently Asked Questions

What is the basic process for making milk powder?

The process involves pasteurizing and standardizing raw milk, followed by evaporation to remove a large portion of the water, and finally spray drying or roller drying to create a fine powder.

What are the different types of milk powder?

The main types are whole milk powder, skimmed milk powder (SMP), and buttermilk powder. Skimmed milk powder is the most widely produced due to its longer shelf life and lower fat content.

What are the key applications or uses of milk powder?

Milk powder is used in a wide range of products, including confectionery, bakery items, infant formula, and as a convenient ingredient for reconstituted milk.

What are the main quality control measures?

Quality control involves testing the chemical composition (fat, protein content), microbiological quality to ensure it’s free from harmful bacteria, and checking for moisture content to guarantee a long shelf life.

How is the shelf life of milk powder extended?

The shelf life is extended by removing almost all of the water, which inhibits microbial growth. Proper packaging in air-tight, moisture-proof containers is also crucial to prevent rehydration and oxidation.