Copper wire drawing is a vital process within the manufacturing of copper wires, which are important for a number of industries, especially electrical, automotive, telecommunications, and construction. The demand is increasing across the globe; therefore, it is important for entrepreneurs and startups to understand the wire drawing process, market data, trends, and growth potential, to enter the market.

Understanding Copper Wire Drawing

What is Copper Wire Drawing?

Copper wire drawing is a process of metalworking used to decrease the diameter of a copper wire or rod by drawing it through a series of dies. The wire’s diameter is reduced, while the mechanical properties are improved, such as strength or ductility, making the wire appropriate for various applications in the industry.

Key Applications for Copper Wire

Copper wires are known for their excellent electrical conductivity, thermal conductivity, and corrosion resistance. Therefore, they are used in electrical wiring in homes, businesses, and industrial establishments. Also, they are used in telecommunication systems to transmit data, wiring harnesses in automobiles and electrical components, grounding or electrical wiring in construction applications, and renewable energy applications (i.e., wind and solar energy).

Market Outlook and Growth Prospects

Global Market Size and Forecast

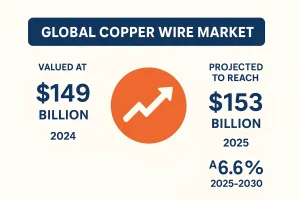

Experts estimated the global copper wire market to be valued at around USD 149 billion in 2024 and forecasted that it will increase to approximately USD 153 billion in 2025. The experts also expect the copper wire market to grow at a compound annual growth rate (CAGR) of 6.6% between 2025 and 2030, potentially reaching USD 210 billion by the end of the decade.

Factors fueling market growth

The demand for copper wire is expected to increase due to several factors. The global transition to renewable energy and the electrification of transportation systems are leading to increased opportunities for copper wire. There is also the telecommunication infrastructure demand due to the rollout of 5G networks and additional data centers that are supporting the copper wire market. In addition, the substantial demand for electric vehicles and new automotive technologies, with an increased reliance on copper wire, will support growth for copper wire. Finally, increased recycling initiatives and programs are expected to increase sustainable manufacturing of copper wire and improve cost efficiency.

Regional Analysis

Detailed project report on Copper Wire Drawing

The Process of Manufacturing Copper Wires

Wire Drawing

The first step involves a copper rod drawn through dies of progressively smaller size in order to reduce its diameter and lengthen the wire. This strengthens the wire and increases ductility.

Annealing

Once the wire has been drawn, it is annealed, which is a heat treatment in order to relieve internal stresses and increase ductility, allowing further processing as needed for product applications.

Spooling

The wire is wound onto spools or coils while maintaining tension on the wire to facilitate uniform spooling and to prevent tangling, to assure the wire’s usability.

Quality Control

Related articles:- Feasibility and Techno-Economic Viability Study on PVC Coated Wires & Cables Industry

Updates to Technology

Automation and smart manufacturing have recently improved efficiency and precision in wire drawing operations. For example, automated systems provide continuous measurements of key parameters, including temperature, tension, and speed, which help to ensure product uniformity. Furthermore, producers are incorporating sustainability initiatives into their processes, such as using environmentally friendly lubricants and allowing recycling of water and energy.

Visit our books for additional information

C.opper Wire Drawing Challenges

The availability of raw materials can vary and introduce volatility in production costs and the stability of the supply chain. Environmental regulations may require manufactured investments in waste disposal or the installation of emission–managed systems. Additionally, businesses must continue to invest in and upgrade technology as the industry is ever-changing, and competition is fierce.

Opportunities for Entrepreneurs

Role of NIIR Project Consultancy Services (NPCS)

NIIR Project Consultancy Services (NPCS) is a leading consultancy that supports entrepreneurs in setting up new industries. NPCS prepares Market Survey cum Detailed Techno-Economic Feasibility Reports, which include manufacturing processes, raw material requirements, plant layout, and financial insights. These reports are invaluable for evaluating the feasibility and planning of new ventures in the copper wire drawing industry.

Conclusion

The copper wire drawing industry presents significant opportunities for startups and entrepreneurs. Its crucial role across multiple sectors, coupled with robust market growth, makes it an incredibly attractive business avenue. Furthermore, by understanding the manufacturing process and analyzing market dynamics, new entrants can gain a deeper insight into the industry’s nuances. Additionally, leveraging consultancy support from NPCS can help businesses navigate challenges effectively. As a result, startups can strategically position themselves for long-term success in this expanding industry.

Find best business ideas for yourself using our startup selector tools

Frequently Asked Questions

What is copper wire drawing, and why is it important?

Copper wire drawing is a process that reduces the diameter of copper rods or wires by pulling them through a series of dies. This process strengthens the wire, improves ductility, and makes it suitable for use in electrical, automotive, construction, and telecommunications applications. It’s crucial because copper wire is foundational to modern infrastructure and technology.

What are the main industries that use copper wire?

Industries widely use copper wires for electrical wiring, telecommunications (data cables), automotive wiring harnesses, construction (grounding systems), and renewable energy systems such as solar panels and wind turbines.

What factors are driving the growth of the copper wire market?

Key growth factors include global electrification, renewable energy adoption, expansion of telecommunications networks (including 5G), the rise of electric vehicles, and increasing recycling initiatives for sustainable manufacturing.

How is copper wire manufactured?

The manufacturing process includes:

- Wire Drawing: Pulling copper rods through a series of dies to reduce diameter.

- Annealing: Heat treatment to relieve stresses and restore ductility.

- Spooling: Winding the wire onto spools or coils for easy handling.

What are the challenges faced in copper wire drawing?

Entrepreneurs may face challenges such as fluctuating copper rod prices, strict environmental regulations, and the need for continuous technological upgrades to maintain efficiency and product quality.