Business of Eco-friendly products and packaging and products are no longer niche, but a necessity as the world moves towards sustainability. The manufacturing industry is being forced to change its design, source and distribution methods as consumers, governments, and multinational corporations actively push for greener options.

This shift offers entrepreneurs and startups a great opportunity to create new businesses that are aligned with the values of the future. The path to sustainability is not without its challenges, ranging from the limitations of raw materials to scaling issues. This article explores the complex landscape of sustainable packaging and manufacturing, looking at the long-term outlook, market potential, and process considerations.

Why Sustainable Manufacturing is a Global Trend

Sustainability has become a business imperative in recent years. Climate concerns, plastic pollution, and growing consumer awareness are the main reasons for this. The younger demographics are more concerned about the environmental impact of products, from the way they are made to the way they dispose of them.

This means that manufacturers must rethink their traditional methods, invest in cleaner technologies and comply with new regulatory standards. This means that it’s not enough to make a functional product; the product also needs to align with values such as low carbon footprint, ethical sourcing, and circularity.

Government action in countries such as India, where industrialization has increased, is a major factor behind the focus on green manufacturing. This includes bans on plastics and new regulations regarding extended producer responsibility.

Related: Packaging Made of Mushrooms: An Eco-Friendly Substitute for Plastic

Global Demand Outlook and Market Growth

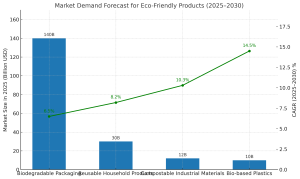

Eco-friendly packaging and products are experiencing a steady rise in demand. Recent projections show that the biodegradable package market will reach 140 billion dollars by 2025. This is a growth rate of 6.5%. The consumer demand for reusable products like cloth bags, bamboo containers, and compostable items is also creating a new category of essentials.

The growth of the packaging industry is not solely driven by consumers. B2B buyers, including large FMCG companies and hospitality chains as well as logistics providers, are actively looking for sustainable packaging partners in order to achieve their ESG goals. The demand for eco-friendly materials has spread across many sectors, including foodservice and electronics.

India is in a good position to become a hub for manufacturing eco-products. The country has access to agricultural products like bagasse and bamboo as well as a large number of micro- and small businesses.

The Challenges of Manufacturing Eco-Friendly Products

Even though the demand for eco-friendly products is booming, it can be difficult to start a business. If not anticipated, there are several obstacles that can slow growth for entrepreneurs who are new to the field.

The lack of availability of sustainable raw material is one of the greatest challenges. These materials, whether they’re biodegradable starch-based plastics or agro waste like areca leaves, aren’t always available or of consistent quality. Some are only available in certain regions or seasons, while others require special processing.

Another barrier is competitiveness. Eco-friendly items are typically more expensive than mass-produced plastics due to the use of costly raw materials, special machinery or slower processing speed. Pricing products at a competitive price while maintaining high quality can be difficult for a new startup.

Next comes the complex compliance. It is not enough to use alternative materials when it comes to manufacturing green products. Each product must comply with domestic and international standards–especially for packaging or food-contact items. It can be time-consuming and expensive for new businesses to comply with certifications, testing and audits.

Scalability also poses a problem. Manual processes are fine for prototypes and small batches, but to scale up into a medium-sized operation will require automation and quality assurance systems that differ from those used in traditional plastic manufacturing. Compostable containers, for example, may require lower temperatures and different drying mechanisms than plastic molds.

A Closer Look at the Manufacturing Process

Consider a typical example: making biodegradable tables from sugarcane bags, a byproduct produced in the sugar industry. The first step is to collect and clean the bagasse fibers, then pulp it into a slurry. The pulp is then pressed using hydraulic presses to apply heat and pressure. After the product is formed, it is dried, trimmed and inspected before being packaged.

Other eco-friendly production methods use similar techniques. To create reusable cloth bags, for example, natural fabrics such as cotton or jute are cut, sewn into the required sizes and printed or dyed. Bio-plastics are made of corn starch and cassava. They go through a polymerization to create materials that look like traditional plastics while still being compostable.

Each product type has its own set of tools, processing parameters and environments. Startups must understand the process flow in detail, how materials behave under pressure or heat, and their shelf life.

Related: Eco-Friendly Products and Packaging: Meeting the Growing Demand

New Opportunities for Entrepreneurs

The growth opportunities are enormous and growing. Customized packaging solutions are one of the most promising. As corporations are pushed to meet ESG goals and by regulatory frameworks, there is a growing interest in bulk quantities of biodegradable or recyclable packaging. Startups that can provide quality and scale can secure long-term contracts.

A second option is to create niche products that have strong sustainability narratives. The story is what consumers are buying, not the product. Bamboo toothbrushes packaged in recycled paper, sold by brands that plant trees for every purchase, resonate more than generic eco-products. These products are well-suited to direct-to-consumer marketing channels such as marketplaces and social networks.

Material science and product design are also areas where innovation is possible. Many Indian startups are developing innovative products such as edible packaging to deliver food, water-soluble films or cartons with embedded seeds that grow into plants when discarded. These are not only sustainable but also unique and marketable–especially for global buyers looking for innovation.

Export capacity is a powerful tool that cannot be underestimated. The US, Germany and Australia are the leading importers of eco-friendly packaging and products. Indian manufacturers that can meet certification standards and provide a consistent supply are well-positioned for these markets.

Institutional and Policy Support

The government policy plays an increasing role in shaping this sector’s growth. India’s ban on single-use plastics has led to a surge in demand across all states. MSME and Startup India programs offer incentives to green manufacturers, including grants, tax breaks, and soft loans.

Globally, regulatory frameworks such as the EU Green Deal and California’s Plastic Packaging Laws encourage businesses to adopt sustainable sourcing. This has a ripple effect, causing the supply chain to respond with eco-friendly innovation.

Startups that align themselves early with these frameworks and invest in quality control and compliance will likely gain an edge over competitors still exploring the traditional models.

View our handbooks on Environmentally Friendly, Eco-Friendly Products, Natural Products, Biodegradable Plastics, Natural Dyes and Pigments, Jute Products, Natural Fibers

Global Market Trends and Export Trends

Export markets are a huge opportunity for Indian eco-product manufacturers. Sugarcane-based disposables, for example, are becoming more popular in the US and Europe because of strict bans on Styrofoam or single-use plastic.

Importers in Germany are actively searching for bio-based packaging materials to be used by the food and cosmetics industry. Australian consumers are looking for biodegradable household products. Even Middle Eastern countries, who are transitioning to a sustainable lifestyle, are looking at compostable products for large events, hotels, and aviation.

Manufacturing companies that have certifications such as USDA BioPreferred or ISO 17088 can form strong partnerships with global partners. Export incentives under India’s Trade Development Programs can also be beneficial to them.

For more information, check out this related video

The role of NPCS as a supporter of eco-manufacturing projects

Expert guidance and a structured feasibility analysis can be of great benefit to entrepreneurs exploring eco-friendly products manufacturing opportunities. Niir project Consultancy Services (NPCS) is a key player in this area.

NPCS offers Market Study cum Detailed Techno-Economic Feasibility Reports to help assess the feasibility of launching eco manufacturing projects. The reports provide insights into the manufacturing process, raw material sourcing and plant layout design. They also contain comprehensive Financial Projections.

NPCS has decades of experience in assisting entrepreneurs in assessing the feasibility of setting up new industries. This ensures that their ventures have sound technical and marketing foundations.

Find the Best Idea for Yourself With Our Startup Selector Tool

Conclusion – Green is the Future – Build It Today

Eco-friendly manufacturing offers more than just a way to combat climate change. It’s also a great business opportunity. The sector, from compostable packaging to reusable items, is set for a massive transformation in the next decade. Startups and entrepreneurs who enter the market today will benefit from the strong demand, as well as from export incentives, regulatory support and a growing consumer consciousness.

But success depends on much more than good intentions. This requires a thorough understanding of the material sciences, workflows and processes, compliance with market regulations, and reliability in supply chains. Whoever invests in innovation, knowledge, and quality will not only be able to survive, but will also lead.