Biodegradable Alternatives to Plastic: The non-biodegradable plastic products, which are commonly used in households, cannot be recycled for 400 years. Products like plastic carry bags, if disposed of unscientifically, are hard to decompose and are a massive threat to soil cultivation.

Biodegradable substances are those that degrade or break down naturally. Materials like plants, animals, their waste, paper, fruits, flowers, and vegetables fall under biodegradable substances; on the other hand, rubber, plastic, chemicals, and paint fall under the category of non-biodegradable items.

Jute Garments

Jute is a vegetable fiber. It is very cheap to produce, and its production levels are similar to those of cotton. It is a best fiber, like hemp and flax. Like all natural fibers, Jute is biodegradable. Jute is one of the important natural fibers widely used for diverse textile and non-textile applications. Jute is mostly used as packaging and other technical textiles, whereas cotton is mostly used as apparel textiles, but both jute and cotton are commonly used for furnishing and decorative upholstery products as home textiles. Cotton comes in the first position in terms of worldwide consumption of natural fibers, and jute comes next to cotton in this aspect. Jute is a lignocellulose, multicellular, best fiber and is mainly cultivated in India, Bangladesh, and its subcontinent.

Jute has been used in our countries for centuries, with more than four million livelihoods depending on it today. It is an important natural crop for Bangladesh also. It is obtained from the stem of the two varieties of plants- Corchorus Capsularis and Corchorus Clitoris. The Indian textile and apparel market was worth US$102.2 billion in 2018. The market is expected to reach US$225.7 billion by 2024, growing at a CAGR of 14.2% during 2019-2024. India represents the largest producer of jute and cotton and the second-largest producer of silk.

Related: Start Own Profitable Journey: How to Set Up a Jute and Coir Products Business

Biodegradable Disposable Plastic Cutlery

Plastics are plastics that can be decomposed by the action of living organisms, usually microbes, into water, carbon dioxide, and biomass. Biodegradable plastics are commonly produced with renewable raw materials, micro-organisms, petrochemicals, or combinations of all three. Plastic cutlery is made from a type of plastic known as polystyrene. Polystyrene or expanded polystyrene is more commonly referred to as Styrofoam. India is slowly becoming a country where people are turning health-conscious.

Thankfully, biodegradable cutlery has emerged as a better alternative to plastics across the globe, and Indians have been early adopters of biodegradable products. The biodegradable plastic packaging market was valued at USD 3.97 billion in 2018, and is expected to reach a market value of USD 10.3 billion by 2024, registering a CAGR of 17.04% during the forecast period of 2019 – 2024. Increasing awareness regarding the harmful effects associated with non-biodegradable plastic waste is a key factor likely to drive the market.

Paper Bags for White Cement Packaging

A paper bag is a bag made of paper, usually Kraft paper. Paper bags are commonly used as shopping bags, packaging, and sacks. A paper sack is a shipping container made of high-quality and weight paper, usually Kraft virgin fiber, which is normally used for transporting powder materials, such as flour, cement, animal feed, etc. Multi-wall paper bags usually have several layers of heavy-duty Kraft paper, sometimes with a highly printed paper on the outside. Paper bags also offer many eco-friendly benefits to those who use them.

They can be taken care of and continually reused. They are both recyclable and biodegradable. Paper bags are made from a renewable natural resource, can be reused repeatedly and can be shipped to a paper mill and remade into new paper. The paper bags market is expected to grow at a CAGR of 4% during the forecast period of 2019-2029. Growing numbers of malls, supermarkets, and a strong retail sector are boosting global demand for paper bags.

Biodegradable Plastic Pellets

Biodegradable plastics are made from all-natural plant materials. These can include corn oil, orange peels, starch, and plants. Traditional plastics contain chemical fillers that harm the environment when melted. The biodegradable plastics market is projected to reach USD 6.12 billion by 2023 at a CAGR of 15.1%. Rising eco-conscious consumer demand and strict plastic regulations are driving this growth.

Consumer demand for eco-friendly products and government support are driving the biodegradable plastics market. However, high costs and performance issues may slow growth. Still, rising use in food, beverages, and packaging continues to fuel market expansion.

Related: Manufacturing Business of Biodegradable Plastic Pellets and Biodegradable Plastic Products

Paper Napkins, Toilet Rolls & Facial Tissue

The tissue paper sector has boomed over the last few years. With a move to more luxurious tissue paper and ultra-absorbent paper towels, the industry has been able to increase the tissue prices and create new brands to retain consumers. Tissue can be made from both virgin and recycled paper pulp. Majorly, there are five types of tissue papers, namely Bathroom Tissue, Facial Tissue, Paper Towel, Paper Napkin, Specialty, and Wrapping Tissue. A napkin, serviette, or face towelette is a rectangle of cloth used at the table for wiping the mouth and fingers while eating. It is usually small and folded, sometimes in intricate designs and shapes.

Toilet paper is a tissue paper product used by people primarily for the ablution of the anus and surrounding area of fecal material after defecation and by human females for cleaning the perineal area of urine after urination and other bodily fluid releases. It also acts as a layer of protection for the hands during these processes. It is sold as a long strip of perforated paper wrapped around a paperboard core for storage in a dispenser near a toilet. Most modern toilet paper in the developed world is designed to decompose in septic tanks, whereas some other bathroom and facial tissues are not.

Polyester Fiber from Corn/Starch

PLA (Polylactic acid) comes from fermented plant starch (mostly from corn), and is often referred to as corn starch plastic. It is becoming popular very quickly because corn-based plastic is a more environmentally friendly alternative to traditional plastics, which are petroleum-based. Polyester fibers are manufactured from recycled or virgin PET. These fibers can be colored by the method of pigmentation or dope dyeing. Polyester fibers can be classified as staple fibers and bulk continuous fibers (BCF) depending on their length. These fibers can also be manufactured in various geometries, such as square, rectangular, triangular, hexagonal, and circular, depending upon the area of application.

Polyester is the most used and most preferred fiber in the textiles industry due to its better physical properties, lower price, versatility, and recyclability, which offer a completely unique set of benefits unmatched by any other natural or synthetic fibers. Polyester fibers are extremely strong, resistant to most chemicals and shrinking, stretching, abrasion, wrinkling and mildew.

PET Pre-Form from PET Resin

A PET preform is a test tube-shaped piece of plastic that is made by a process called injection molding, using a plastic called PET. Meanwhile, a world is a shaped hollow piece of metal, a tool that is used to control the shape of the item being molded. Preform is to form or shape a product to a preliminary shape and size. In easy words for PET Preforms, the PET (Polyethylene Terephthalate) material is formed to a shape which is like molded into a shape that is then blown into a bottle in the blowing machine. PET Preforms market size will grow from USD 18.5 Billion in 2017 to USD 25.95 billion by 2023, at an estimated CAGR of 5.8%.

Polyethylene terephthalate (PET) refers to a thermoplastic polymer resin of the polyester family, which is widely used for manufacturing plastic bottles. In comparison with PP, HDPE, and PVC bottles, PET bottles are more durable, transparent, lightweight, non-reactive, and cost-effective, and thermally stable. Moreover, they are environment-friendly and can be recycled repeatedly, which further reduces their manufacturing cost. PET bottles are mainly used for packaging water and beverages. They’re also widely used for salad dressings, cleaners, medicines, detergents, and mouthwashes.

Production of Bio-Plastic Film Using Biodegradable Resin, PLA (Polylactic Acid)

PLA Polylactic Acid, is a biodegradable thermoplastic and aliphatic polyester, derived from renewable and organic resources such as corn starch and sugarcane. Our manufacturing facilities can provide simple cut-to-size or complex CNC manufacturing, and crating for multiwall and twin wall sheet. Polylactic acid or polylactide (PLA) is a thermoplastic aliphatic polyester derived from renewable resources. PLA had the second-highest consumption volume of any bioplastic in the world. Although bioplastics are a biodegradable material that comes from renewable sources and can be used to reduce the problem of plastic waste that is suffocating the planet and polluting the environment.

These are 100% degradable, equally resistant and versatile, already used in agriculture, textile industry, medicine, and, overall, in the container and packaging market, and biopolymers are already becoming popular in cities throughout Europe and the United States. With increasing concerns over the use of plastics, sustainable alternatives to plastics are increasingly in demand. Biopolymers in general and bioplastics in particular present one such sustainable alternative.

For more information, check out the related videos

Pet Bottles

PET, which stands for polyethylene terephthalate, is a form of polyester (just like the clothing fabric). It is extruded or molded into plastic bottles and containers for packaging foods and beverages, personal care products, and many other consumer products. The global PET bottle market reached a volume of more than 17 Million Tons in 2018, registering a CAGR of 2.3% during 2011-2018. The market is further projected to reach a volume of nearly 19 Million Tons by 2024, at a CAGR of 2.1% during 2019-2024. Polyethylene terephthalate (PET) refers to a thermoplastic polymer resin of the polyester family, which is widely used for manufacturing plastic bottles.

In comparison with PP, HDPE, and PVC bottles, PET bottles are more durable, transparent, lightweight, non-reactive, cost-effective, and thermally stable. Moreover, they are environment-friendly and can be recycled repeatedly, which further reduces their manufacturing cost. Primarily used in the packaging of drinking water and beverages, PET bottles are also gaining prominence as a packaging solution for salad dressings, household cleaners, medicines, dish detergents and mouthwashes. Moreover, Asia-Pacific is expected to witness high growth in the high-end pet bottles market due to a rise in the consumption of food and beverages.

Biodegradable Plastic Products (Bags, Plates & Glasses)

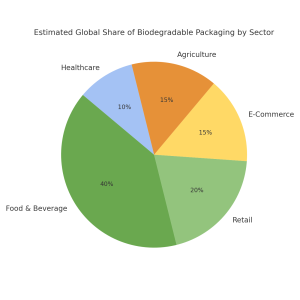

Biodegradable plastic is plastic that decomposes naturally in the environment. This is achieved when microorganisms in the environment metabolize and break down the structure of biodegradable plastic. The result is less harmful to the environment than traditional plastics. The global biodegradable plastics market is anticipated to reach USD 6.12 billion by 2023 at a CAGR of 15.1%, from USD 3.02 billion in 2018.

The packaging and the bag industry is one of the major factors for the growth of the global biodegradable plastics industry. It is anticipated to be the fastest-growing end-use industry segment of the biodegradable plastics market between 2018 and 2023.

One of the leading sectors for biodegradable plastics is packaging. It is used in flexible and rigid packaging. Conventional plastics are now being replaced by biodegradable plastics in food packaging, such as cups, plates,and wraps, which is further boosting the biodegradable plastics market. Another reason for the driving growth is the rising consumer awareness towards sustainable plastic solutions. The market is witnessing a significant boost due to the agricultural sector as well.

Which business to start? How to choose a Business idea?

Frequently Asked Questions (FAQs)

1. What are biodegradable Plastics, and what are the differences between them and traditional plastics

Biodegradable materials are made of natural substances like corn starch or sugarcane. Biodegradable plastics decompose naturally, with the aid of microbes, into carbon dioxide and water. They are better for the environment, and they don’t have toxic residues.

2. Why are plastics considered to be a major threat to the environment?

Decomposition of plastic products, such as bags and packaging materials, can take 400 years. Unsafe disposal can lead to soil contamination, water contamination and damage to wildlife. These substances also clog drains and release toxic chemicals in the ecosystem.

3. What are the benefits of jute for textiles and packaging?

Jute, a natural and biodegradable fibre, has been used in India for centuries. The fiber is inexpensive to make and can be used for packaging, furniture, and decor. Jute, unlike synthetic fibers decomposes in nature and provides a livelihood for millions of rural farmers.

4. What are the possibilities of biodegradable cutlery?

As Indians become more health- and environment-conscious, there’s a rising shift toward using biodegradable cutlery made from starch or PLA. This market will reach USD 10,3 billion in 2024 due to increasing environmental regulations and the ban on single-use disposable plastic.

5. Can paper bags replace cement and retail packaging effectively?

Yes. Paper bags are used more and more to package cement, flour and other consumer goods, especially Kraft paper bags. These bags are lightweight, biodegradable and recyclable. Paper bags are in high demand due to retail chains, food services, and the construction industry.

6. What is biodegradable pellet plastic, and why is it important?

Plastic pellets can be used as raw material to manufacture plastic products. They are a good source of sustainable plastics when made from biodegradable materials like corn starch and orange peels. These pellets have been widely used for packaging and food in recent years.

7. How important is it to use tissue paper in an eco-friendly way of living?

Toilet rolls, napkins and facial tissue are all now made of recycled or virgin pulp. Growing demand is a result of increased hygiene awareness and lifestyle changes. Tissue paper is lightweight, biodegradable and convenient for personal hygiene.

8. What exactly is PLA, and how does it work in bio-polyester films and fibers?

Polylactic acid (PLA), a polymer made from corn starch, is a plant-based material. It is used to make biodegradable fibers and films. PLA is used widely in food packaging, medical devices, and textiles. It’s an eco-friendly replacement for petroleum-based plastics.

9. What are the major drivers of the biodegradable market?

Major growth drivers include consumer demand, environmental regulations and the ban on single-use disposable plastics. In addition, sectors like retail, agriculture, pharmaceuticals, food packaging and the retail industry are actively looking for sustainable alternatives to reduce carbon footprints.

Key Takeaways

The environmental harm caused by traditional plastic especially single-use items like bags and cutlery is driving a global shift toward biodegradable alternatives. Materials like jute, paper, PLA (polylactic acid), and plant-based resins are emerging as eco-friendly solutions that naturally break down without polluting soil or water. India, being a major producer of jute and cotton, is well-positioned to lead in sustainable textile and packaging innovations. Products like Kraft paper bags, biodegradable cutlery, and bio-films are rapidly gaining market share across retail, food, and hygiene sectors. Though cost and infrastructure remain challenges, rising consumer awareness, government regulations, and a growing focus on circular economy practices are accelerating the adoption of biodegradable products across industries.