Steel is a very important material in modern life. We use steel is in everything from the houses we live in to our vehicles, to bridges and machines. To make steel we need sponge iron, a special raw materials. Sponge iron, also known as Direct Reduced Iron or DRI, plays an important role in the production of high-quality steel.

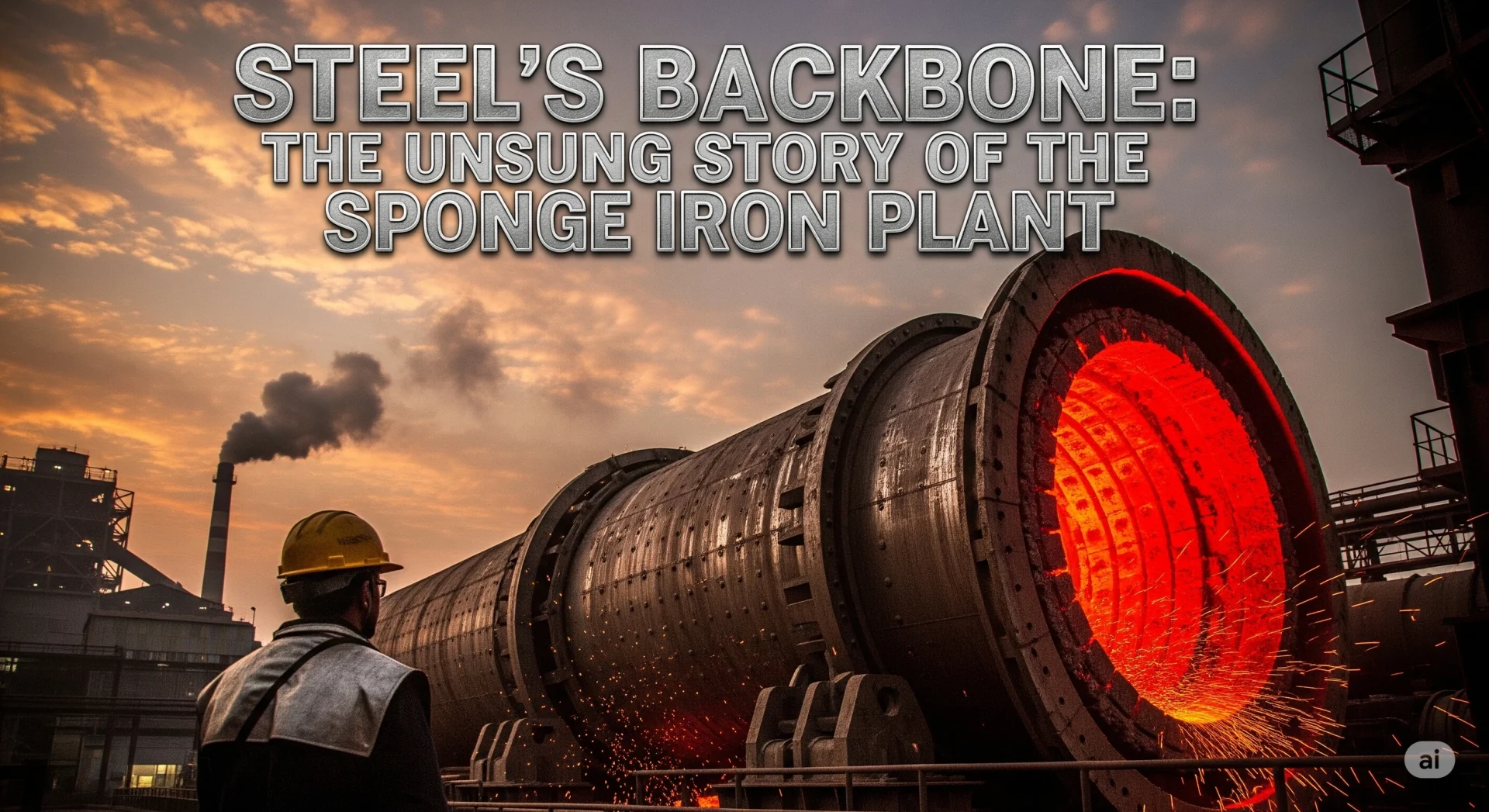

A sponge iron factory is a place where iron ore, through a process known as direct reduction, is transformed into sponge iron. This method differs from the blast furnace method in that it does not melt ore. It removes oxygen by heating iron ore to high temperatures with coal or natural gases. The final product has a solid texture with a porous surface that resembles a sponge.

This expanded article will describe in simple terms what sponge iron is. We will also explain how it’s made, the different types of sponge-iron plants, the raw material requirements, their benefits, challenges and future prospects. You will get a better understanding of the importance of sponge iron plants for the steel industry.

What is Sponge Iron

Sponge Iron is obtained by directly reducing the iron ore, without melting it. Direct reduction is the name of this process. This process involves removing oxygen from ore by using reducing agents such as coal or natural gases. Sponge iron is a solid lump, unlike molten pig-iron from blast furnaces.

The iron is known as “sponge iron” because it has many tiny holes or pores on its surface, giving the appearance of a sponge. The pores form when the oxygen from the ore is removed while maintaining its solid shape. Sponge Iron is a highly reactive material with a high iron content. It’s an ideal raw material for steel plants to use in electric arc and induction furnaces.

List of Profitable Business Ideas in Production of Iron and Steel Products

The Raw Materials Required in a Sponge Iron Plant

The sponge iron plant needs several raw materials.

- Iron Ore: It is the main raw material. The iron ore can come in pellets or lumps. It is best to use high-grade ore, but lower-grade ore may also be used if it has been properly prepared.

- Non-Coking coal: Used both as a fuel, and as a reducing agent for sponge iron plants that use coal. The coal should have a low ash and a high fixed carbon content.

- Natural Gas: It is used in the gas-based sponge-iron plants instead of coal. The result is a cleaner product with fewer impurities.

- Dolomite or Limestone: These minerals can be used to remove impurities such as sulphur during the processing of iron ore.

- Water: Water is essential for cooling, dust suppression, and other plant operation.

- Electricity: Electricity is required to operate the conveyors and run machinery.

A sponge iron plant can’t operate effectively without these raw materials.

Sponge Iron Manufacturing Process

Depending on the fuel, manufacturer can produce sponge iron using either coal or gas.

Coal-based Sponge Iron Process

In India, coal-based DRI is the most common because it is readily available. The steps in the process are:

- Raw Material Preparation: They crush and screen the iron ore, and size the coal. Limestone or dolomite gets prepped as flux.

- Feeding Rotary Kilns: A large horizontal cylindrical furnace slowly rotates. The iron ore, coal and flux is fed into the one end.

- Direct Reduction: The temperature inside the kiln reaches about 1000degC – 1050degC. The coal is burned, releasing carbon monoxide which reacts with iron ore and removes oxygen.

- Formation of Sponge Iron: The ore transforms into metallic iron that has a sponge texture.

- Cooling: To keep the sponge iron from oxidizing, they dump it in a rotary cooler.

- Screening and storage: After cooling, they screen out impurities and store the finished product.

Gas-based Sponge Iron Process

he shaft furnace is where the process occurs.

- Gas Reforming: They zap natural gas into hydrogen and carbon dioxide.

- Direct Reduction: They run that gas through iron ore pellets to pull out the oxygen.

- Product Recovery: They stash the iron and let it cool.

The gas-based sponge iron plant is cleaner and has fewer pollutants compared to the coal-based plant.

Sponge Iron: Uses and Benefits

- Steel Manufacturing: As a raw materials in electric arc furnaces and induction kilns.

- Blending with Scrap Steel: Improves the quality and quantity of steel produced from scrap.

- Special Steel Production: Used to make stainless steels and alloy steels.

- Foundries: For producing high-quality cast iron products.

Read Our Steel and Iron Handbook

Key Advantages

- High Purity – Fewer impurities compared to scrap steel.

- Consistent Quality – Controlled manufacturing results in uniform composition.

- Energy Efficiency – Direct reduction requires less energy than blast furnaces.

- Flexibility – Can use low-grade iron ore and still produce good-quality iron.

Sponge Iron Plants: Challenges and Opportunities

Although sponge iron plants are important to the industry, they face challenges.

- High coal consumption – increases production costs.

- Pollution issues – Control of dust, gases and solid waste.

- Water Use – large quantities of water are necessary for cooling and dust control.

- Raw Material Quality – Poor quality ore and coal will reduce efficiency.

- Equipment Maintenance – Rotary Kilns need frequent maintenance.

Environmental Impact and Solutions

Bag filters and electrostatic precipitators? They rip dust right out of the air. Seriously, if you’ve ever worked around heavy machines, you know you need these just to breathe.

Waste heat recovery boilers? Brilliant move. Instead of letting the kiln’s heat disappear, these things grab it and turn it into electricity. You’re saving cash and keeping the lights on—no extra fuel needed.

Water recycling systems? Absolutely. Water isn’t getting cheaper, so why waste it? These systems clean up used water and run it through again. Factories save money and help the planet.

Switching to gas? Do it if you can. Coal and oil are outdated and filthy. Gas burns way cleaner—your lungs (and the environment) will thank you.

Tree planting? Not just for show. Trees trap dust and freshen up the place. Plus, the greenery makes the factory look way less grim.

And finally, let’s talk tree planting. Plant crews get those saplings in the ground all around the plant, not just because it looks nice (although, honestly, it does), but because trees are natural dust-catchers. They grab all those tiny particles floating around and keep the air fresher. Plus, more green space makes any industrial site look less like a villain’s lair and more like somewhere real people want to work.

So yeah, if you want a cleaner, smarter operation, these are the moves to make. No magic involved—just some solid tech and a bit of common sense.

SPONGE IRON – Manufacturing Plant, Detailed Project Report

Future of Sponge Iron Plants

Steel demand will continue to increase in the future, especially for infrastructure, manufacturing, and construction. Future trends include

- Expansion Gas-based DRI Plants for cleaner production.

- Automate more to improve efficiency and lower labor costs.

- Improved Pollution Control to meet environmental regulations

- Integration with Steel Plants to reduce transportation costs and increase production speed.

Want To Know About Which Business Idea Would Be Better For You?

Go Through Our Startup Selector Tool

Conclusion

The sponge iron plant plays a crucial role in the process of steelmaking. These plants provide steelmakers with high-quality raw material by converting iron ore through direct reduction.

While there are still challenges such as pollution and high fuel prices, improvements in cleaner technology and improved efficiency make sponge iron plants more durable. While steel demand is increasing globally, sponge-iron plants will continue to be a solid foundation for the building of the future, including skyscrapers, railways, bridges and automobiles.

FAQs About Sponge Iron Plants

Q1. What is sponge iron used for?

It is mainly used to produce steel in electric arc and induction furnaces.

Q2. Why is sponge iron called direct reduced iron?

Because it is made by directly removing oxygen from iron ore without melting.

Q3. Which countries produce the most sponge iron?

India is the largest producer, followed by Iran.

Q4. Is gas-based sponge iron better than coal-based?

Yes, it has fewer impurities and causes less pollution.

Q5. Can I use sponge iron without melting?

No, it needs to be melted in a furnace to make steel or other products.