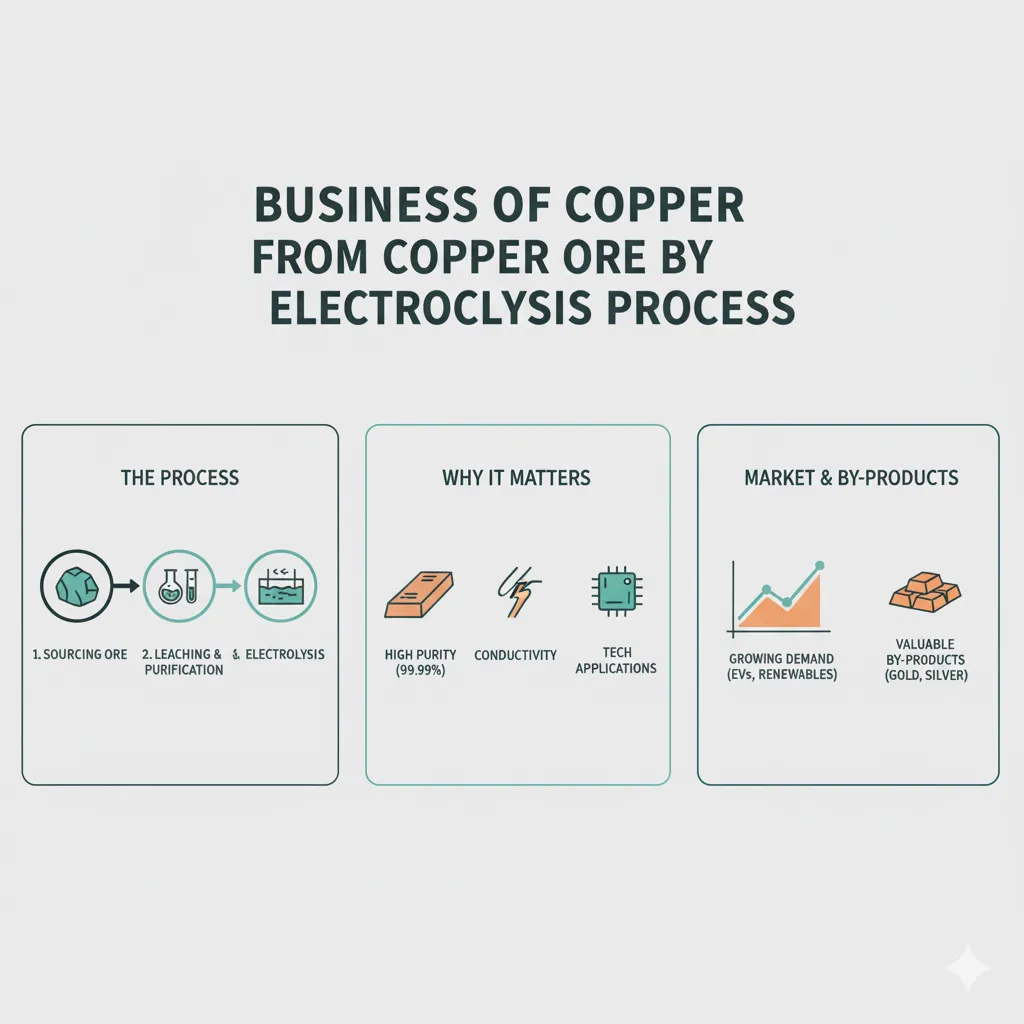

Copper has powered human progress for centuries. From the earliest tools and coins to modern electrical grids and renewable energy systems, this reddish-brown metal has played a vital role in industry and society. Today, copper remains one of the most important metals in the global economy. Its unmatched electrical and thermal conductivity make it indispensable for industries ranging from construction and automotive to electronics and renewable energy. Processes like Copper Ore Electrolysis further highlight its significance, ensuring the production of high-purity copper that meets the demands of advanced technologies.

For entrepreneurs and startups, copper offers more than industrial importance. It represents opportunity. As global demand grows, especially with the rise of electric vehicles and green energy, the copper sector creates space for innovation, investment, and business growth. Understanding the extraction and refining process is crucial for anyone interested in this field. It helps identify opportunities not only in mining but also in recycling, manufacturing, and value-added services.

This article explores the journey of copper from ore to refined metal. It also highlights its key applications, market dynamics, and business opportunities for emerging entrepreneurs.

Detailed project report

Global and Indian Market Trends

The Global Copper Landscape

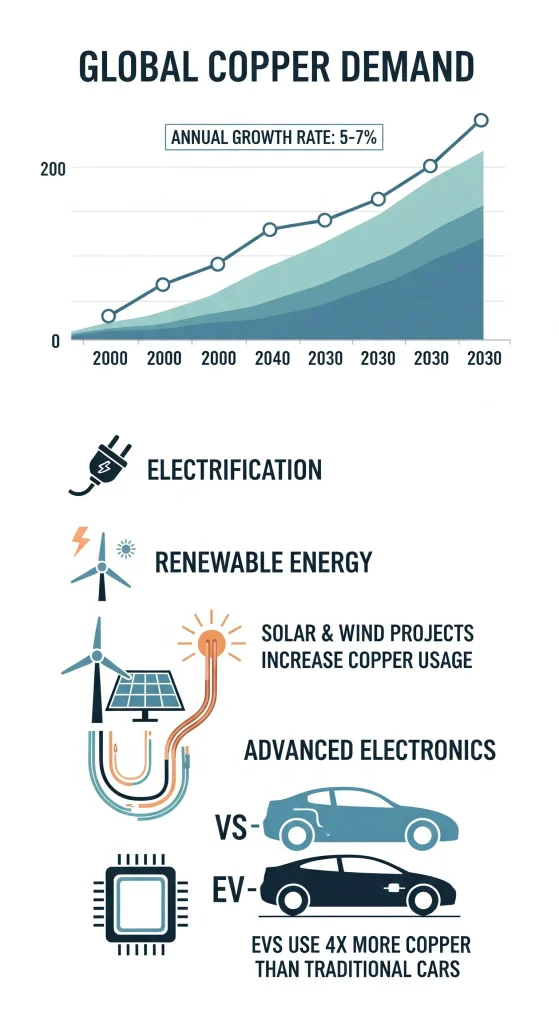

Globally, copper demand is rising steadily. The shift toward electrification, renewable energy adoption, and advanced electronics drives this growth. According to market research, copper demand is projected to grow by 5–7% annually over the next decade. Renewable energy projects, particularly solar and wind power, require vast amounts of copper for wiring and components. Electric vehicles use up to four times more copper than traditional cars, creating a significant boost in demand.

Countries with strong mining bases, such as Chile, Peru, and China, continue to dominate global production. However, new opportunities are emerging in recycling and sustainable practices. Investors are also paying close attention to supply chain challenges, rising extraction costs, and the need for eco-friendly solutions.

The Indian Copper Industry

India holds a unique position in the copper market. While the country has some mining capacity, its domestic demand exceeds local supply, making it a net importer. Industries such as power generation, telecommunications, transportation, and electronics rely heavily on copper. Rapid urbanization and the government’s focus on infrastructure development further drive demand.

The growth of India’s electric vehicle sector, renewable energy targets, and smart city projects strengthens the need for copper. Entrepreneurs can explore opportunities in recycling, wire manufacturing, alloy production, and value-added services. With policy support for Make in India and sustainable practices, copper-related businesses hold strong growth potential in the Indian market.

To explore more, check our books.

The Extraction Process

Mining and Concentration

Copper extraction begins with mining ores from open-pit or underground mines. The most common copper ores are chalcopyrite, bornite, and malachite. After extraction, the ore undergoes crushing and grinding to reduce it into smaller particles. This makes it easier to separate copper minerals from waste rock.

Concentration follows through froth flotation. In this process, chemicals are added to create froth, which binds to copper particles. These particles rise to the surface, where they can be collected, leaving behind unwanted material. This step increases copper concentration and prepares it for smelting.

Smelting

The concentrated ore moves to smelting, where high temperatures separate the metal from sulfur and iron. The process produces copper matte, which contains about 60–70% copper. Further refining removes impurities, creating blister copper with around 98–99% purity.

Electrolytic Refining

The final stage is electrolytic refining. In this process, impure copper serves as the anode, while pure copper plates form the cathode. An electric current passes through an acid solution, dissolving copper from the anode and depositing it onto the cathode. This produces copper with 99.9% purity, ready for industrial use.

Recycling as a Parallel Process

Alongside primary extraction, copper recycling plays an increasingly important role. Scrap copper, from old wires, pipes, or discarded electronics, can be reprocessed with lower energy use compared to mining. Recycling reduces environmental impact and meets part of the growing demand. Entrepreneurs can build profitable ventures around the collection, sorting, and refining of scrap copper.

Key Applications of Copper

Power and Electrical Infrastructure

Copper is central to the power industry. Its high conductivity makes it ideal for electrical wiring, transformers, and motors. As countries expand their power grids and invest in renewable energy, copper demand continues to grow.

Electronics and Telecommunications

Smartphones, laptops, and communication devices rely on copper for circuits and connectors. With the rise of 5G and IoT, copper will remain vital to modern electronics.

Automotive Industry

Electric vehicles are reshaping the automotive market. Each EV uses 60–80 kilograms of copper, compared to about 20 kilograms in conventional cars. This surge creates massive business opportunities for copper manufacturers and recyclers.

Construction and Infrastructure

Buildings use copper in plumbing, roofing, and heating systems. Urbanization and smart city projects ensure steady demand in the construction sector.

Renewable Energy

Wind turbines, solar panels, and energy storage systems use copper extensively. The global push for clean energy makes this sector one of the fastest-growing markets for copper.

Related article:- Copper is one of those essential metals that is often used in many industries.

Business Opportunities for Entrepreneurs

Copper Recycling Ventures

Recycling is one of the most attractive opportunities. Startups can build businesses around scrap collection, sorting, and processing. With growing sustainability demands, recycled copper often sells at competitive prices.

Wire and Cable Manufacturing

Electrical wires and cables account for a significant portion of copper consumption. Entrepreneurs can explore small- and medium-scale manufacturing units to meet local demand.

Copper Alloys and Products

Alloys like brass and bronze create additional opportunities. Industries use them in machinery, decorative items, and industrial equipment. Entrepreneurs can target niche markets with customized alloy products.

Export Opportunities

India’s role as a copper importer means that domestic manufacturers can tap into both local and export markets. High-quality refined copper and copper-based products find steady demand across Asia, Europe, and North America.

Technology and Innovation

New business models can focus on eco-friendly extraction techniques, AI-driven recycling systems, or energy-efficient refining methods. Startups with innovative solutions can attract funding and partnerships in the growing green economy.

Sustainability and Future Outlook

Environmental Challenges

Traditional copper mining and smelting can harm the environment through emissions, waste, and energy use. Regulatory frameworks increasingly demand eco-friendly practices, opening doors for sustainable solutions.

Green Innovations

Recycling, renewable energy integration, and water-saving technologies are reshaping the copper industry. Entrepreneurs who embrace green methods will gain an edge in future markets.

Global Demand Projections

Analysts predict that global copper demand will almost double by 2035. Electric mobility, renewable energy, and urbanization will continue to fuel this trend. India, with its growing population and industrial base, will remain a significant contributor to global demand.

Conclusion

Copper extraction and refining form the backbone of many industries. For entrepreneurs and startups, this sector holds diverse opportunities ranging from recycling and wire manufacturing to exports and green innovations. With demand rising in power, electronics, transportation, and renewable energy, copper will continue to shape the global economy.

By focusing on sustainable practices and value-added services, businesses can position themselves for long-term growth. The journey of copper—from ore to refined metal—offers not only technical insights but also pathways for entrepreneurial success. Those who recognize its potential today will build the foundations of tomorrow’s industries. Trial development.

Discover the best business ideas for yourself using our startup selector tools.

Frequently Asked Questions

What is the electrolysis process in copper production?

The electrolysis process, also known as electrorefining, uses an electric current to purify copper. An impure copper anode and a pure copper cathode are placed in an electrolytic solution. As electricity passes through, copper from the anode dissolves and is deposited onto the cathode, resulting in very high-purity copper.

Why is high-purity copper so valuable?

High-purity copper (typically 99.99% pure) is essential for applications where electrical conductivity is critical, such as in wiring, electronics, and telecommunications. The purity ensures minimal resistance, which is vital for efficient power transmission and signal integrity.

What are the main types of copper ore used in this process?

The primary types of copper ore are sulfide ores like chalcopyrite and oxide ores. Sulfide ores are typically concentrated and then smelted before being sent for electrorefining. Oxide ores can be treated through a process called solvent extraction and electrowinning, which also uses electrolysis.

What are the main by-products of the copper electrolysis business?

The main by-products of the electrolysis process are precious metals like gold, silver, and platinum, which settle at the bottom of the electrolytic cell as “anode slime.” This slime is then processed to recover these valuable metals, adding another revenue stream to the business.

What are the key market drivers for the copper business?

The primary market drivers for the copper business are global industrialization, urbanization, and the transition to renewable energy. Copper’s use in construction, electric vehicles, and power grids ensures a consistent and growing demand.