More and more solar panels We see on roofs or in open areas. They quietly convert sunlight to electrical energy for homes and businesses. Ever wondered what goes into making one?

It may seem complicated but you can understand it by taking a step-by-step approach. Sand is the main component. This guide will explain the Solar Panel Manufacturing process.

Solar Panel Manufacturing Journey: A Step-by-step Process

Manufacturers create solar panels through a precise, multi-stage process, closely monitoring each step to ensure durability and efficiency.

Step 1: Start The Process With Sand

Quartz sand is the first step. The sand has a high concentration of silicon dioxide. First, workers extract silicon from quarries, then transport it to a processing plant. At the plant, they heat the sand in a furnace to extremely high temperatures, producing metallurgical-grade silicon.

Related Article: Solar Panel Manufacturing: Sunlight to Power

This silicon, however, is still not pure enough for use in solar panels. Purity of silicon is extremely important, at least 99.9999%. A complicated chemical purification procedure can help achieving this. This process produces a form of ultra-pure silicon, called polysilicon.

Want To Know About Which Business Idea Would Be Better For You?

Go Through Our Startup Selector Tool

Step 2: Form The Solid Blocks Of Silicon

The next step is to melt the polysilicon at temperatures above 1,400°C in another furnace. The remarkable process of transformation begins once the liquid silicon has melted to a glowing liquid.

To create the ingot, manufacturers dip a perfect small piece of silicon (seed crystal), into molten silicon and slowly pull it out while rotating. The molten silicone cools as it moves, solidifying around the seed crystal to copy its exact structure.

This solid block is a large cylinder or rectangular block. The solid block of silicon, known as an ingot, undergoes a carefully controlled process, as its quality directly influences the panel’s performance.

Read Our ‘Solar PV Power and Solar Products Handbook‘

Step 3: Slice Ingots Into Thin Wafers

Now the solid ingot of silicon is ready for cutting. The very hard ingot is then cut using diamond-tipped saws into ultra thin discs. Wafers are the thin discs.

The wafers are typically smaller than the hair of a person. After cutting, workers meticulously clean the wafers to remove impurities or dust from the process. They smooth the edges and polish the surfaces to ensure they are perfectly flat. The thin wafers will form the basis of the solar cells.

Related Article: Profitable Guide to Solar Panel Plant Setup Cost in India for Smart Entrepreneurs

Step 4: Transform Wafers Into Solar Cells

The most important stage is when the silicon wafer becomes a device capable of generating electricity.

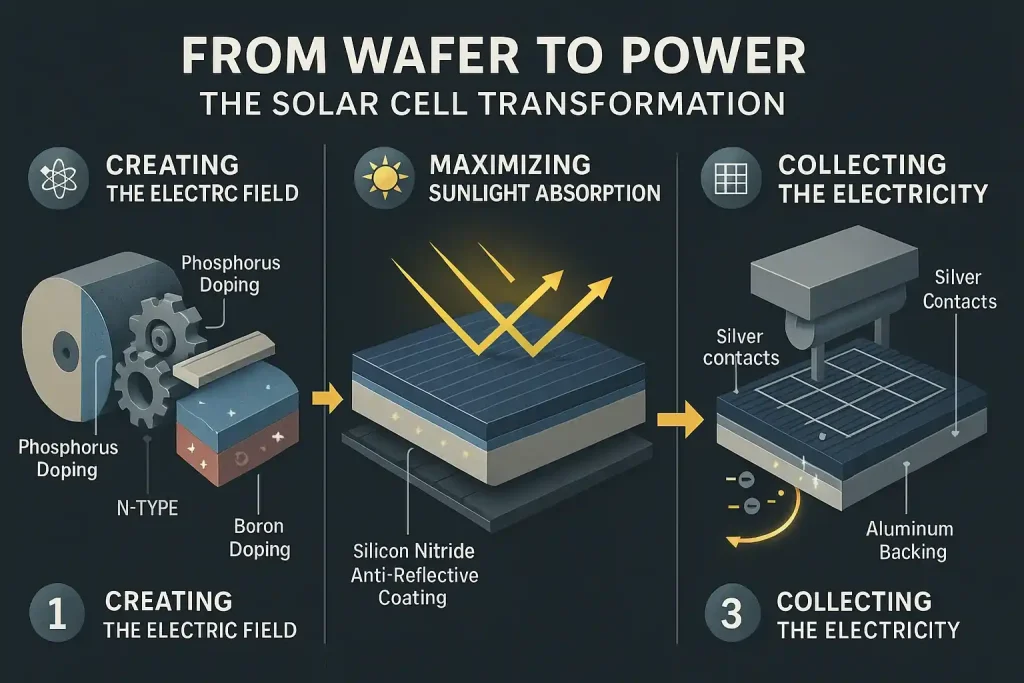

Manufacturers treat the wafers to produce an electric field through doping. They introduce elements like phosphorus to dope the top side of the wafers. The result is a negative layer (n-type) with more electrons.

A layer without electrons is created by doping the rest of the wafer with boron. This layer, which we call the p type (positive), has no extra electrons. This junction is the area that meets these two layers. The junction at the center of the cell is called the p-n junction. The junction becomes active when sunlight hits it.

Maximum Sunlight Absorption: A glossy silicon wafer will reflect away a large amount of light. An anti-reflective layer is placed on the surface of the cell to prevent this. The coating, which is usually silicon nitride in a dark black or blue color, has an anti-reflective surface.

This coating allows more light to be absorbed into the cell, rather than being reflected.

The Cell Collects Electricity: Since the cell is able to produce electricity, it needs a method of collecting that energy. Screen-printed thin lines of metallic paste, usually made from silver, are applied to the front surface of each cell.Contacts are the thin lines.

On the rear of the cell is usually a thin layer of aluminium. The metal contacts on the cell are necessary to capture the electricity generated by sunlight.

Read Our Project Report: Click here

Final Step: Assembling Your Panel

One solar cell does not produce much electricity on its own. Many cells need to be linked together in order to create an amount of useful electricity.

The cells are first laid out on a grid. Producers solder the cells together using thin metal ribbons. They carefully position a series of cells connected in series on a high-transmission layer of glass, followed by a polymer backsheet. Between the layers is a special encapsulant (like EVA).

In the manufacturing process, the entire stack—including glass, encapsulant, cells, another layer, backsheet, and an additional encapsulant layer—enters a lamination machine. This machine heats and presses the stack together. Encapsulant seals the stack into one durable and weatherproof piece.

The final step is to fit an aluminum frame around the perimeter of the rectangle. The frame is strong and easy to install. The back of the panel is fitted with a junction box. The wiring in this box allows for the panel to connect to another panel or an electrical system. After the panel has been completed, it will be cleaned and checked one final time.

Solar Panel Manufacturing: Conclusion

From sand, to solar panels that work is an amazing feat of modern engineering. The transformation of a common material involves a number of carefully controlled processes, including intense heat, chemical cleansing, precision cutting and meticulous assembly.

From creating the silicon ingot to laminating the final panel, each step is carefully designed for durability and efficiency. Once the final panel is complete, installers prepare it for installation. It will quietly convert sunlight to clean, renewable energy, benefiting our planet, over many years.

Solar Panel Manufacturing: FAQs (Frequently Asked Question)

Q1: What is the main material of solar panels?

A: Most solar panels consist primarily of silicon, a very common element extracted from quartz sand. Manufacturers typically construct the frame from aluminum and cover it with tempered glass.

Q2: What is the reason for most solar panels being blue or black?

A: The anti-reflective layer that has been applied to silicon solar cells is the cause of the dark colour. The coating ensures that the solar cells absorb more light and reflect less, making the panels more efficient.

Q3: For how long can a solar cell be expected to work?

A: Solar panels of all types are built to last and can effectively function for 25-30 years. After this period, their electricity production decreases but does not completely stop.

Q4: Does the manufacturing process for solar panels harm the environment?

A: Solar panels don’t just magically appear—they chew up plenty of energy and materials during production. But honestly? Once they’re up and running, they pay it all back and then some.

Q5 Can solar panels recycled?

A: Solar panels can indeed undergo recycling. Specialized recycling facilities recover different components, such as the silicon cell, aluminum frame, and glass. Manufacturers can use the recovered materials to create new products.