Urea Formaldehyde UF85 is a very much preferred thermosetting resin, known to have very good adhesive properties, strength, and moisture resistance. It is mainly used in the wood, paper, and textile industries due to these properties’ ability to bond well. The UF85 Production Process, in turn, is very important in the production of the final product in terms of quality and efficiency.

In this article, we will cover the UF85 Production Process, advantages, and Applications of Urea Formaldehyde UF85 in order to analyze in detail what makes it a choice resin for various industries.

For more information: Business Ideas and Investments Opportunities

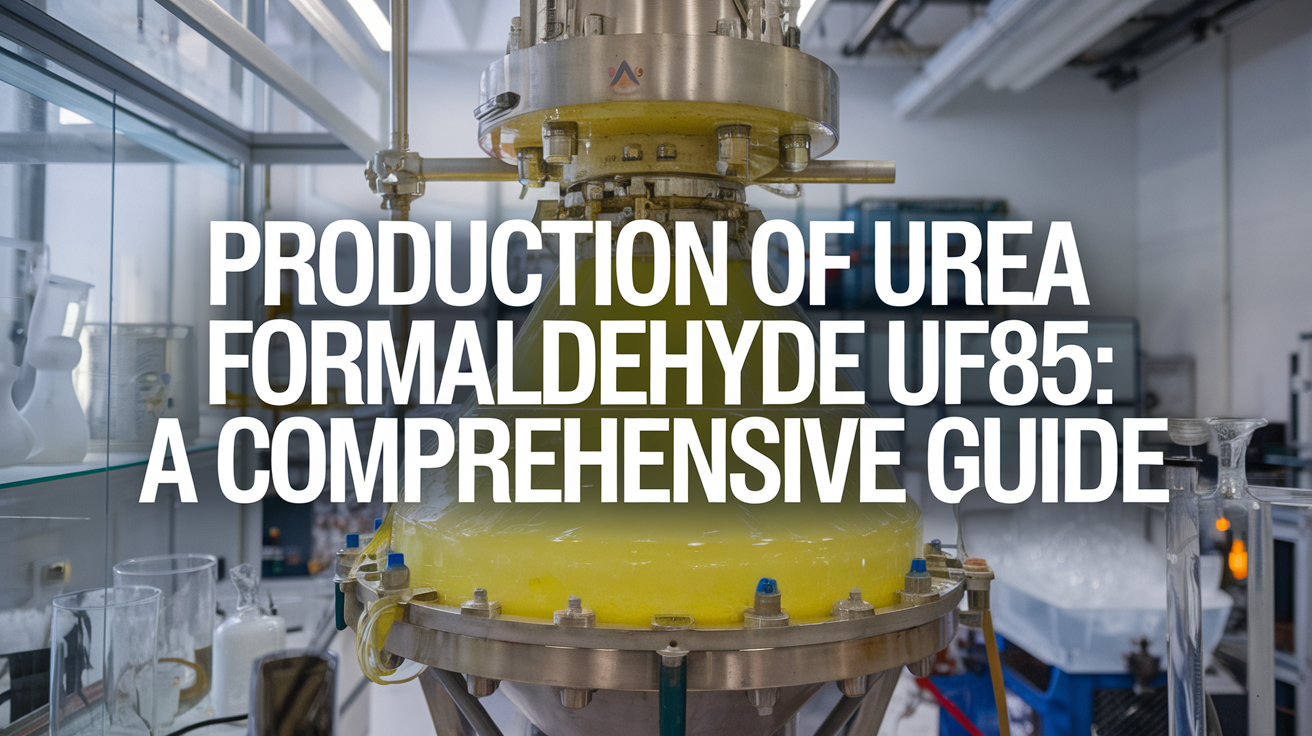

Understanding the UF85 Production Process

What is UF85?

This type of resin is formed as the result of the chemical reaction between urea and formaldehyde, which are mixed in controlled conditions. The UF85 Production Process consists of a sequence of observations that will guarantee the desired properties of the final product, in which case it becomes suitable for a number of industrial applications.

UF85 Production Process: Step-by-Step Guide

1. Raw Material Selection

The first step undertaken during the UF85 production process is to ensure selection of the best quality raw materials, whose two main components are:

- Urea (CH₄N₂O)- A colorless and odorless compound, which is basically the main polymer-building material.

- Formaldehyde (CH₂O)- It is a pungent-smelling compound and acts as a cross-linking agent in the polymerization reaction.

Business Plan: Production of Urea Formaldehyde UF85

2. Mixing and Reaction

Urea Formaldehyde UF85 production begins when controlled amounts of urea and formaldehyde are mixed in a reactor. The reaction is done under acidic or alkaline conditions based on the properties that are desired in the final product..

3. Polymerization

During this phase of the UF85 Production Process, polymerization occurs, with the urea and formaldehyde interacting to yield a tough and durable resin. This step is critical to high molecular weight and excellent adhesive properties.

4. Filtration and Drying

After polymerization, the resin is then filtered to remove any impurities and dried to obtain Urea Formaldehyde UF85 in powdered or granulated form.

5. Quality Testing

The last stage before packaging would really seem to be the quality control of the finished products to determine whether it conforms to industrial standards. Testing would include:

- Adhesion strength

- Moisture resistance

- Thermal stability

Project Reports: Urea Formaldehyde UF85

Applications of Urea Formaldehyde UF85

Applications of Urea Formaldehyde UF85 has an enormous range because of its good bonding capability and cost-effectiveness. The various uses for it have made this resin a must-have for industries all over the world.

1. Wood and Plywood Industry

Largely, one of the uses of Applications of Urea Formaldehyde UF85 would be in the wood industry. These include the following:

- Adhesive for:

- Plywood manufacture.

- Particle board manufacture.

- Medium-density fiberboard (MDF).

Its high bonding strength will keep wooden products durable and stable.

2. Textile Industry

Use in the textile industry is also yet another one of the excellent Applications of Urea Formaldehyde UF85 in fabric finishing. Some interesting applications are:

- Wrinkle resistance.

- Durable fabric.

- Smooth and polished finish.

3. Paper Industry

Urea Formaldehyde UF85 is also used in the paper industry for:

- Paper strength.

- Water resistance.

- Ink absorption properties.

Related Article: Why and How to Start a Urea Formaldehyde Manufacturing …

4. Molding Compounds

Applications for Urea Formaldehyde UF85 also extend into the manufacture of molding compounds that render hard plastic components for the purposes of:

- Electrical switches.

- Automotive parts and components.

- Household appliances.

5. Coating and Paints

The UF85 Production Process facilitates resin utilization for coatings and paints in improving:

- Surface finish

- Scratch resistance

- Color fastness

6. Agriculture and Fertilizer Industry

The Urea Formaldehyde UF85 is also applicable to slow-release fertilizers, ensuring nutrients persist with the plants for an extended period.

Download PDF: Production of Urea Formaldehyde UF85- …

Advantages of UF85 Production Process

The UF85 Production Process is engineered to attain efficiency and quality standards of the highest degree, with all inputs being placed in an industry perspective. Some important benefits include:

- High Adhesive Strength- This innovative product bonds with long-lasting effects in the wood, textiles, and paper industry.

- Cost Efficient- A cheap alternative to other resins.

- Environmental Friendliness- Can be formulated for lower formaldehyde emissions, consistent with modern safety standards.

- Resistance to Water- Guarantees improved protection of wood and paper products against moisture.

- Improved Durability- Lengthens life for end-products.

Future of UF85 and Market Trends

The demand for Urea Formaldehyde UF85 is evolving rapidly with a growing number of applications especially in construction, automotive, and consumer goods industries. Due to the advances in the UF85 Production Process, manufacturers are also coming up with more environmentally friendly and low formaldehyde versions to meet global environmental regulations.

The market is predicted to see:

- Rise in demand in the construction industry for plywood and MDF boards;

- Further studies and advancements in polymer technology to upgrade the performance of Urea Formaldehyde UF85;

- Stricter policies on formaldehyde emissions causing adaptation in manufacturing processes.

Youtube Video: Production of Urea Formaldehyde UF85 | Start Own Industry of Urea Formaldehyde.

Conclusion

The UF85 Production Process is the most important one in producing high-quality Urea Formaldehyde UF85, hence preferred by a number of industries. The thermosetting resin undoubtedly rules the market with its vast application areas, from wood to textiles, paper, coatings, and molding.

With the demand for green alternatives rising, Applications of Urea Formaldehyde UF85 will be searched for everywhere as one of the most prominent industrial materials. Companies upgrading the UF85 Production Process through technology will walk with a competitive edge embracing sustainability and innovation for the resin industry.

For the procurement of reliable Urea Formaldehyde UF85, insight into the UF85 Production Process is essential, ensuring high performance and quality standards. Urea Formaldehyde UF85 will therefore maintain its indispensable status across various sectors due to continuous improvement in production methods.

Note: For any query related to starting this business, you can reach out to us through our contact form or mail.