The potato is an icon of global cuisine. This humble tuber has been cultivated for thousands years and is loved by billions for its affordability, versatility, and comforting taste. It’s boiled, fried or mashed. We also know how to bake it. What happens when you transform this common vegetable into a fine powder that is shelf-stable? Potato powder is one of the underrated, but essential ingredients in modern food.

Potato powder, often working in the background, is a powerful source of convenience, nutrition and functionality. The secret ingredient in instant soups, sauces, and gluten-free breads, potato powder gives them a creamy, thick consistency. It also adds a crispy coating on fried chicken. This product is the perfect marriage between agricultural tradition and modern science. This article will explore the many layers of this amazing product. It will explain what it is, describe how it’s made, discuss its benefits and examine its surprising range of uses, from large food processing plants to your own kitchen pantry.

What is Potato Powder exactly?

Potato Powder, at its most basic, is the result of freshly cooked potatoes that have then been dried and ground to a fine powder or granule. It’s important to differentiate it from its cousins, potato starch and flour.

- Potato powder/flour: This is a product made from the whole potato, which is usually peeled. It contains all the nutrients, vitamins and minerals of the potato, as it is made from the entire vegetable. The color is off-white to yellowish and it’s a whole food ingredient.

- Potato Starch : Not the same as The potato starch that is extracted from the crushed potatoes after it has been cleaned and refined is pure carbohydrate. The fiber, flavor, and protein of the potato are thrown away. The powder is white, very fine and flavorless. It’s used as a thickener, much like cornstarch.

If you’re looking for the convenience and nutrition of potato powder, then you are on the right track. You can use potato starch to thicken sauces without changing their flavor.

Read More: How to Start the Manufacturing Business of Potato Powder

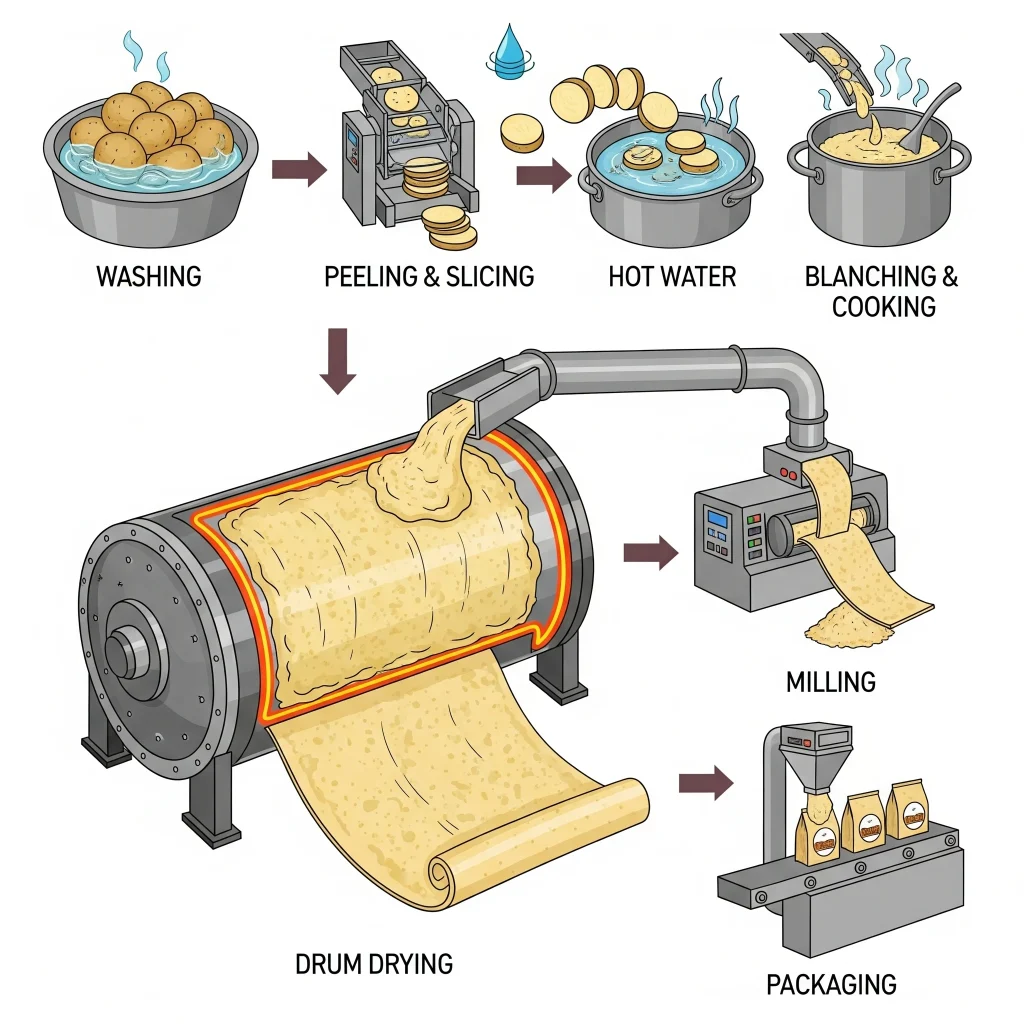

Manufacturing Process: From Field to Powder

A multi-stage, precise industrial process is used to transform a firm earthy potato into dry powder. This ensures maximum quality, safety and shelf life.

Selecting and cleaning high-quality potatoes

To prevent browning, manufacturers choose varieties that have a high solid content. The potatoes are then transported to the processing plant, where they undergo an intensive cleaning process using rotating brushes and water jets to remove any dirt, stones or field debris.

Peeling and Slicing

To get a smooth end product, potatoes must be peeled. This is done in large-scale operations using steam peelers which use high pressure steam to loosen skins or abrasion peelers with rough rotating surfaces. After peeling the potatoes, they are then cut into thin uniform slices in order to cook and dry them evenly.

Blanching

This step is crucial. The potato slices will be briefly submerged in steam or hot water (typically between 70-95degC, or 160-200degF), for a couple of minutes. Blanching has several important purposes. It cleans the surface and preserves its natural color. Most importantly, it stops enzymes such as polyphenol oxidase from causing the potato to brown or develop bad flavors when dried.

Cooking

After blanching the slices, they are cooked thoroughly with steam to soften and make them ready for mashing.

Dehydration

The heart of the process is dehydration, which is where almost all the water has been removed. drum-drying is the most common industrial drying method.

- Drum drying: The mashed potatoes, once cooked, are applied as a thin, thin film to the rotating surface of a large metal drum. The drum’s high temperature causes the water in the mashed potatoes to evaporate within seconds. A scraper blade is used to remove the dried sheet of potato before the drum has completed its full rotation. The continuous sheet of potato is then cut into smaller pieces, known as potato flakes.

Milling and sieving

The dried potatoes flakes are ground into powder. The powder must be sieved to achieve a fine and consistent particle size. The powder’s fineness can be adjusted according to its final application.

Packaging

The finished powdered potato is finally packaged in moisture-proof, multi-layered bags. The air in the packaging is sometimes removed and replaced by an inert (like nitrogen) gas to further prolong its shelf life.

Potato Powder: Many Benefits

- Shelf life is extraordinary: By removing the water that causes potato powder to spoil, it can be stored for up to 18 months without refrigeration.

- Efficiency and Convenience: It saves time by eliminating the tedious tasks of washing, peeling and boiling. It is pre-cooked and ready to use. You can easily measure it and add it to recipes.

- Nutritional value: Although some heat-sensitive vitamin (like Vitamin C), are reduced to a certain extent, potato powder still retains a large portion of the nutritional profile of potatoes, including complex carbs for energy, potassium in significant quantities, B vitamins and dietary fibre.

- Gluten Free: This is an ingredient that is naturally gluten free, which makes it a great choice for people with celiac or gluten sensitivities. It’s also a good component to use in gluten-free cooking.

- Cost Effective: The product is lighter, less bulky and more compact than fresh potatoes. This reduces transportation and storage expenses. This also reduces the amount of waste that comes from peeling or spoilage.

- Consistency : It is a standard ingredient for food manufacturers that provides consistency in texture, taste, and performance of every batch.

Applications: Industrial Snacks and Homemade Meals

Its greatest strength is its versatility. It can be found in a wide range of foods.

In the Food Industry

- Snack Foods It is used as a binder, texture modifier, and flavor enhancer in products such as potato chips, extruded snack, crackers and veggie straws.

- Sauces and Gravies: This thickening agent creates a smooth creamy consistency, without the pastiness of some starches. It is a key component in many dehydrated soup mixes, and gravy granules.

- Bakery products: It helps retain moisture in both traditional and gluten free baking. This results in a softer crumb, as well as a longer shelf-life for breads and buns.

- Meat and Poultry Product: Widely used in the production of sausages, chicken nuggets, burgers and meatballs. It retains moisture and fat when cooking, which results in a more juicy, succulent product.

- Ready to Eat Meals: This application is the most popular. Instant mashed potatoes are made with potato powder. Also, it is used to make frozen meals, pasta sauces, military food rations and emergency food.

Recommended Project Report Link: Click Here

In Home Cooking

- Thickener Use a spoonful to thicken sauces, stews and chilis just before serving.

- Baking : You can add it to bread dough for a moist and soft loaf. It can be used in gluten-free blends.

- Crispy Coating When mixed with spices, this coating creates an amazing, crispy coating that is perfect for fried fish, chicken or vegetables.

- Homemade Gnocchi This base is quick and easy to make soft, pillowy potato dumplings or other types, saving you hours of preparation.

- Soups : This product can be used to make a cream-style potato soup without using fresh potatoes.

Want To Know About Which Business Idea Would Be Better For You?

Go Through Our Startup Selector Tool

Conclusion

The potato powder is an example of human ingenuity when it comes to food preservation. This powder transforms one of the most important crops in the world into a versatile and stable ingredient that is used for both industrial food production as well as creative home cooking. It is far more than just “instant mash”; it’s a key component of countless products that we use every day. Potato powder is a convenient, consistent and cost-effective way to get the nutritional and textural benefits of potatoes. It also simplifies food preparation and helps reduce food waste. This is a powerful, yet unassuming product that comes from a simple potato.

Potato Powder: Frequently Asked Questions (FAQ)

Q1: Is potatoes powder healthy?

Yes, in moderation. It’s a whole food product made from vegetables and contains good amounts of potassium and carbohydrate. It’s a processed food that is best used as an alternative to potatoes. The fact that it is gluten-free has a great health benefit.

Q2: How do I store potato powder to maximize its shelf-life?

Potato powder should be protected from light, moisture and air. It should be stored in an airtight, sealed container in a dark, cool and dry area like a cupboard or pantry.

Q3: Can I make my own potato powder?

Yes. However, it’s a laborious process. You’d need to boil the potatoes and mash them, then spread it thinly onto baking sheets and dehydrate the mash in the oven at the lowest temperature or a food dehydrator until it becomes completely brittle. After the pieces are dry, they can be ground into powder with a spice grinder or blender.

Q4: Does potato powder expire?

It is shelf-stable but it does not last forever. It can lose its nutritional value and flavor over time. Check the expiration date on the package. It should be thrown out if it starts to smell, clumps up, or shows signs of moisture.