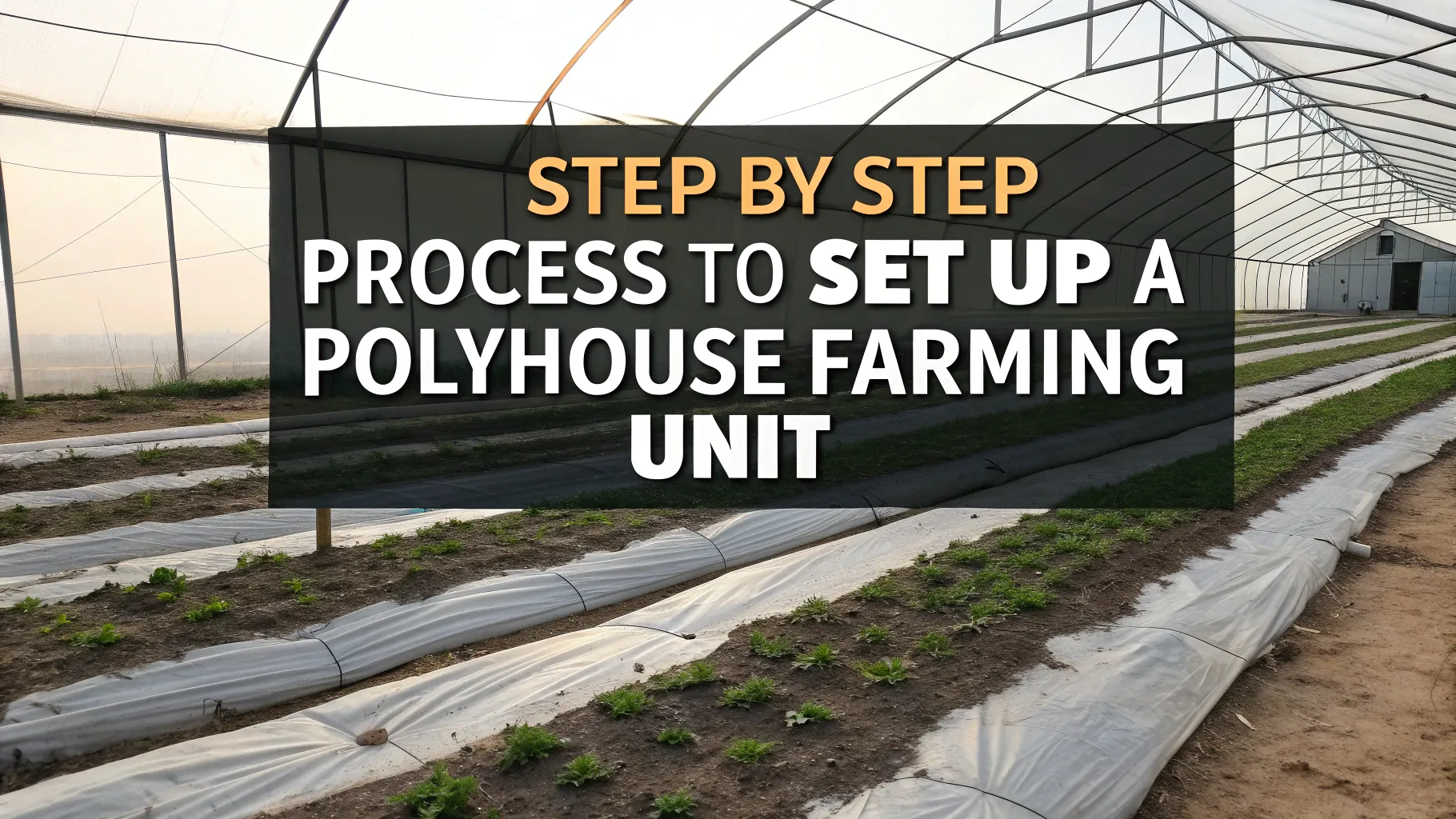

Agriculture is changing fast in India, and one standout innovation is protected cultivation, especially in the form of polyhouse farming. These climate-controlled structures let farmers grow high-value crops like exotic cucumbers and roses all year round. Because of the perfect growing conditions, polyhouses produce more, shrink losses, and earn farmers better profits than open-field growing. That combination is appealing to both seasoned farmers and new agri-entrepreneurs looking to secure steady cash flow.

Startup plans in this space start with knowing how to build and run a polyhouse. This post walks through the step-by-step setup, the market numbers to watch, and the future some smart minds are already mapping out.

Market Outlook for Polyhouse Farming

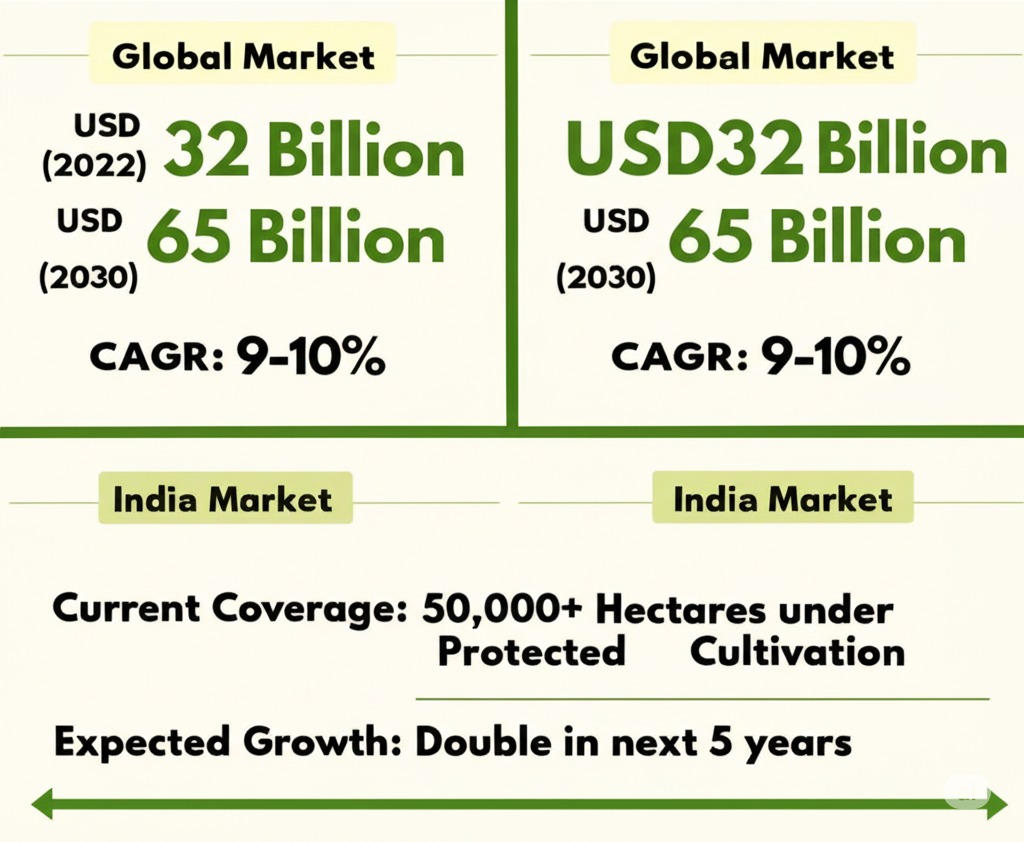

The global polyhouse and greenhouse farming market is witnessing remarkable growth. Valued at around USD 32 billion in 2022, it is projected to reach USD 65 billion by 2030, growing at a compound annual growth rate of nearly 9–10 percent. The demand is fueled by rising concerns about climate change, urbanization, food security, and the need for a year-round supply of high-quality fruits, vegetables, and flowers.

In India, the sector is expanding quickly, driven by both domestic and export markets. As of now, over 50,000 hectares of land are under protected cultivation, and this figure is expected to double in the next five years. With government support, subsidies, and training programs, more entrepreneurs are encouraged to venture into this high-potential business.

Related: Why Rose Farming is a High-Demand Business?

Step 1: Choose the Best Location

Selecting the perfect piece of land is the most critical stage when starting a polyhouse operation. The right site boosts yields, simplifies daily work, and maximizes profits. Look for a plot that enjoys at least 6 to 8 hours of direct sunlight, the main fuel for healthy plant growth. A flat, well-drained, fertile surface with reliable water, power lines, and transportation is a must.

Keep sales in mind, too. Most polyhouse crops—like cut flowers, strawberries, and bell peppers—spoil quickly, so locate the greenhouse near urban areas, grocery chains, cold-storage facilities, or export terminals. Shorter delivery distances lower transport costs and cut the risk of losses from decay.

Step 2: Designing and Constructing the Polyhouse

After securing the right piece of land, your next move is to map out the polyhouse design. Key factors include the crops you’re growing, the weather in your area, and how much you want to invest in technology.

Ready-made polyhouses typically use sturdy galvanized iron pipes, which form a skeleton designed to resist strong winds, heavy rain, and rapid temperature changes. Covering the frame is UV-stabilized polyethylene. This plastic blocks harmful radiation and still lets the right amount of sunlight shine in.

You have a choice of designs. A naturally ventilated polyhouse uses open panels and vents to let fresh air circulate. A fan-pad cooled polyhouse, on the other hand, combines cooling pads and exhaust fans to create a precisely controlled environment. Pick a style that matches your finances and crop needs.

View our Books on The Complete Technology Book on Biofertilizer and Organic Farming

Step 3: Installing Irrigation and Fertigation Systems

Proper water management is key to a successful polyhouse. Most operations use drip lines, which water directly onto the roots and waste almost none. Fertigation systems are paired with the drip lines: by mixing nutrients into the water, growers let the plants get what they need in one pass. Since roots absorb dissolved minerals faster, crops grow stronger and produce more in the same amount of space. Good irrigation also keeps the electric bill lower and the environment cleaner. Polyhouses consume 50 to 60 percent less water than crops grown in the open.

Step 4: Crop Selection and Cultivation Practices

The real money in polyhouses comes from picking the right plants. Growing a crop with a low market value and covering the structure feels like a waste. High-value plants that love controlled conditions and sell for top dollar are the way to go. Flowers like roses, gerberas, and carnations command money in both local and export markets. Vegetables also work: bright capsicum, sweet cherry tomatoes, crunchy cucumbers, and fresh leafy greens are in high demand from city buyers, upscale hotels, and small-chain restaurants. Grow what the city wants, and the polyhouse pays for itself.

Successful growing in polyhouses relies on precision. Farmers plan plant spacing, prune, and train crops, while constantly managing diseases. Because every environmental variable is controlled, optimal temperatures, humidity levels, and soil moisture must be regularly monitored. An integrated pest management plan that balances biological controls with limited chemical sprays reduces risks without hurting the crop.

Related: Why Polyhouse Farming is Changing Indian Agriculture

Step 5: Harvest and After-Harvest Care

Picking polyhouse crops must happen at the perfect moment to keep flavors and market values high. For example, flower stems are harvested when immature buds are just about to open, extending shelf life in transport; strawberries are picked when berries are fully colored but still firm. Capturing that narrow window is critical.

After harvest, grading, removing any soil, and neat, branded packaging can boost shelf presence and profit. When the crops are sent to the market or to export, cool storage keeps the products in prime condition, meaning longer transport and extended sales periods are possible without losses. Smooth logistics and well-planned delivery schedules mean produce arrives at grocery stores or export facilities quickly, helping command the best prices possible.

Step 6: Marketing and Selling Fresh Produce

Even the best-managed polyhouse farm can’t succeed without smart marketing. First, identify clear buyers: local grocery stores, wholesale companies, restaurants, hotels, or overseas markets. Securing long-term contracts with supermarkets or export firms keeps demand steady and protects your price.

Online markets have made selling specialty vegetables and fruits straight to homes easier than ever. By listing your produce on e-commerce platforms, you can reach more buyers. Highlight quality by branding it as premium, pesticide-free, and freshly harvested. Eye-catching packaging and stories about your farm can make shoppers pay more, boosting your income without extra farming costs.

Step 7: Monitor, Automate, and Energize for the Future

The final, ongoing step is to keep watch over the polyhouse environment. Regularly check temperature, humidity, soil moisture, and pest numbers. A small problem today can turn into a serious loss tomorrow. Modern technology makes monitoring easier. Sensors track key metrics, and automated systems adjust fans, misters, and heaters without a worker lifting a finger. This cuts labor and keeps conditions steady, which is vital for consistent yields.

Also, consider switching to solar energy. Installing solar panels to power irrigation pumps and climate systems shrinks electricity costs and makes your farm more eco-friendly. By combining technology and renewables, your polyhouse farm can keep producing tasty vegetables for years while protecting the environment and your profits.

Manufacturing Process of a Polyhouse Structure

Constructing a polyhouse is a bit like running a mini factory. Start with a design that, backed by engineers, maps out the whole frame for the crop and the local weather conditions. Then, the shopping list is created to order the right supplies—GI pipes, clear plastic sheets, shade nets, and just the right irrigation gear.

Next, these parts are cut and bent into the frames and then locked together. Workers stretch and fasten the plastic sheets to build a skin for the house. After that, the polyhouse is fed by the irrigation and fertigation systems so that fertilizer and water can arrive when and where they are needed. Teams double-check everything—joints are tightened, pipes are leak-tested—until the house meets quality standards for strength, flexibility, and the growing environment it will provide for weeks and months ahead.

Future of Polyhouse Farming

The future of polyhouse farming in India is bright. With consumer demand for safe, fresh, and pesticide-free produce continuing to rise, polyhouse cultivation is expected to expand rapidly. Experts predict that by 2030, the protected cultivation sector in India could grow threefold, opening opportunities for entrepreneurs at every level of the agri-value chain. Smart farming tools such as artificial intelligence and sensor-based automation will further revolutionize the sector, making it more efficient and scalable.

For more Information, check out this video

Role of NPCS in Supporting Entrepreneurs

For those planning to start a polyhouse farming business, reliable consultancy is invaluable. Niir Project Consultancy Services (NPCS) plays a crucial role in this journey. NPCS prepares Market Survey cum Detailed Techno-Economic Feasibility Reports for new industries, providing entrepreneurs with insights into demand trends, technical requirements, and market positioning.

Their reports include details on manufacturing processes, raw materials, plant layouts, and financials, offering a complete roadmap for project execution. NPCS helps entrepreneurs assess the feasibility of setting up new industries and farming ventures, reducing risks and increasing chances of success.

Discover the Right Business for You With Our Startup Selector Tool

Conclusion

Setting up a polyhouse farming unit is not just about constructing a structure—it is about creating a complete ecosystem where technology, sustainability, and entrepreneurship come together. From site selection and design to cultivation and marketing, each step requires careful planning and execution. Entrepreneurs who invest in this sector can tap into a rapidly growing market, both domestically and internationally, while contributing to sustainable agriculture.

With the right approach, modern technology, and support from consultancy services like NPCS, polyhouse farming can evolve into a profitable, scalable, and future-ready business model for startups and agripreneurs.