The Electronics PLI scheme has emerged as one of India’s most transformational policy interventions. Since its introduction, the scheme has drawn in investments of over $7 billion, catalyzing cutting-edge manufacturing and creating strong success stories within the PLI in India. The Electronics PLI scheme is rewriting India’s export narrative, having already outlaid ₹2.7 billion and created 91,000 jobs.

In this article, we will explore these PLI success stories in India, delve into what makes up the Electronics PLI scheme, and highlight successful companies under the new incentives.

Understanding the Electronics PLI Scheme

The Electronics Production Linked Incentive (PLI) scheme was spearheaded by the Government of India to promote the domestic manufacturing of electronics and ultimately reduce imports.

Under this scheme, manufacturers are given cash incentives based on the incremental production of goods such as mobile phones, electronic components, and wearable devices. The aim was to attract large foreign and domestic investments, generate employment, and create integrated electronics supply chains.

Objectives under Electronics PLI:

- Lifting domestic manufacturing: Upscaling local plants.

- Attracting global investors: Inducing financial incentives.

- Creating export champions: Bidding to make India a global hub.

- Generating jobs: Creating employment, especially within electronics clusters.

These pillars solidify the meaning of the Electronics PLI scheme beyond just manufacturing. They encompass an incredibly massive scale of PLI success stories in India. From expansion into new and better plants to connecting to global supply chains, companies across India are now responding. So far, the Electronics PLI continues to produce.

₹2.7 Billion Outlay and a $7 Billion Investment Influx

The Electronics PLI scheme commenced with a budget allocation of ₹2.7 billion (₹27 crore) for FY 2021–26 to incentivize large manufacturers. That one number made headlines—and quite rightly so. It laid the groundwork for creating incentives for a rapid scale-up. Thanks to the scheme, investments soared over US$7 billion, far exceeding initial expectations.

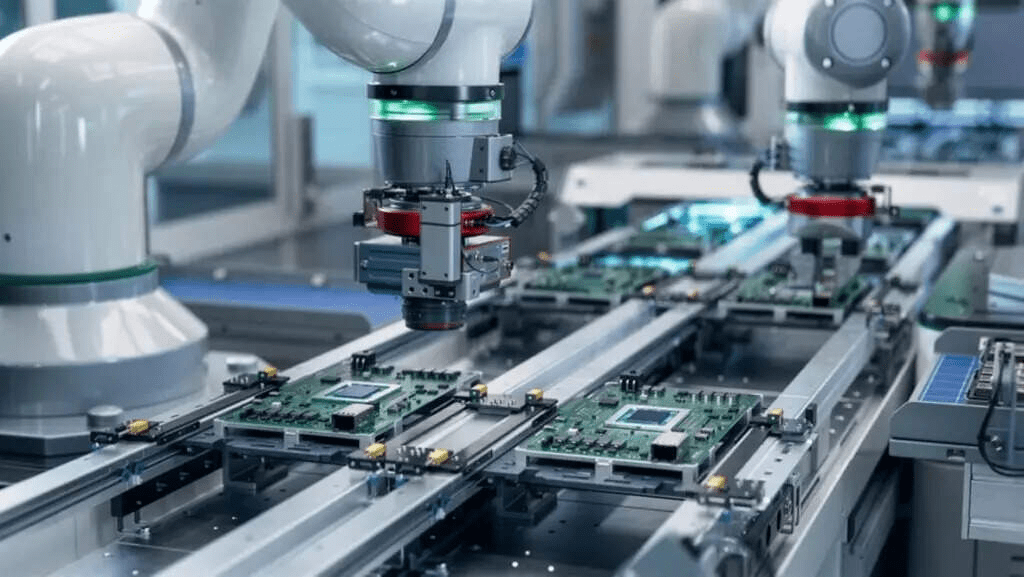

This inflow helped boost expansion across key clusters such as Noida, Tirupati, Bengaluru, and Hyderabad. Global giants and Indian scale-ups made concrete plans for chip plants, PCB assembly lines, and handset units. Not only have these capital investments generated a staggering 91,000 new jobs over the last three years, but they are also central to the PLI success stories in India.

Measuring Impact: 91,000 Jobs Generated

This monumental achievement in job creation is nearly synonymous with the success of the Electronics PLI scheme. Almost 91,000 direct manufacturing jobs have been created across the spectrum of India. These are real jobs for line workers, engineers, and management, validated through both government and industry data.

The jobs cut across several verticals, including mobile device assembly, semiconductor assembly and testing, printed circuit board (PCB) assembly, and components manufacturing. These are concrete examples of PLI success stories from India and prove that achievable results can be measured through strategic national policy.

PLI Success Stories in India — Spotlight on Mobile Manufacturing

Case Study: Leading Global Mobile OEMs

Among the huge collection of PLI success stories in India comes the big news from global mobile manufacturers, who have recently increased production in India by leaps and bounds. Attracted by tiered incentives—an incremental bonus of up to 6% on added volumes—they enhanced productivity by placing large-scale assembly lines in Tamil Nadu, Karnataka, and Uttar Pradesh.

These OEMs now export phones around the globe, from budget smartphones to flagship models. They have driven local sourcing for materials, formed testing labs, and partnered with skill-training centers, reaffirming India’s journey to becoming a global hub for mobile manufacturing.

Case Study: The Emergence of a Component Ecosystem

An equally interesting story under the Electronics PLI scheme is the rise of component manufacturers. Multi-layer PCBs, camera modules, connectors, and even passive components are forming an increasingly diverse ecosystem. Now, many new companies from Pune, Mysuru, and even Tier-II towns provide sub-assemblies to the larger OEMs, both locally and globally.

One leading PCB fabricator, for instance, increased its capacity from 5 million units a year to 20 million units annually, creating new jobs and ramping up exports to Southeast Asia and Europe. This is a notable example of how policy-led ecosystems have created remarkable PLI success stories in India.

Export Boom: How the Scheme Drives Global Sales

Boosting exports is a prominent objective of the Electronics PLI scheme—and it is delivering. Mobile and electronics exports reached record highs in FY 2024, with both exceeding a 30% increase year-on-year.

Companies have credited the PLI incentives for helping them become more cost-competitive and access international markets. For export-oriented firms, the scheme assists them in offering better pricing, quicker delivery, and larger volumes, paving the way for long-term commercial partnerships. These rising exports form solid PLI success stories in India, making India a credible global exporter of electronics.

Entrepreneurial Momentum: Startups & MSMEs Thrive

The Electronics PLI scheme isn’t just for big players; startups and MSMEs are also shining. Several small sensor, meter module, and communication module manufacturing companies have benefited from being grouped with anchor OEMs or by applying directly.

For example, a Hyderabad-based electronics startup scaled up its production of IoT modules within 18 months, attributing its success to PLI incentives that helped in procuring wafer-level production tools and hiring engineers—yet another inspiring story of PLI success in India from the grassroots.

Find all of our books here.

Challenges & What Comes Next

No transformation is without its problems. Some companies have faced delays in approvals, compliance requirements, and infrastructure gaps. However, the central and state governments are working on:

- Fast-tracking application approvals.

- Integrating with other state-level policies.

- Simplifying disbursement processes.

With these efforts, more PLI success stories in India will emerge, and utilization rates for the scheme will rise.

Key Takeaways from PLI Success Stories

- Policies Matter: The Electronics PLI scheme demonstrates how calibrated incentives can attract global capital and motivate domestic capacities.

- Exports Matter: Record electronics exports highlight the scheme’s export-led impact.

- Jobs are Measurable: 91,000 new roles underline the policy’s impact on employment.

- MSMEs are in the Race: Small entities have joined the race, creating a robust electronics ecosystem.

- Momentum is Building: With ongoing reforms, the scheme’s impact will only widen and deepen.

Future Outlook

As we move toward FY 2026, India’s Electronics PLI scheme is evolving. High-value goods like consumer electronics, wearables, automotive electronics, and semiconductor fabs are set to be included.

This next wave will bring fresh PLI success stories in India, larger exports, and deeper technology participation. The sustained focus on capital expenditure incentives, skill development, and exports indicates that this impact should be sustained, positioning India to capture a major share of the evolving global supply chains.

Find the Best Idea for Yourself With our Startup Selector Tool

Conclusion

The Electronics PLI scheme is not a flash in the pan but a game-changer. With a ₹2.7 billion outlay, US$7 billion in investments, and 91,000 direct jobs, it has rewritten India’s electronics handbook.

From global phone OEMs to local PCB assemblers, MSMEs to startups, everyone is contributing to the powerful PLI success stories in India. With ecosystem building, export acceleration, and policy improvements underway, this is only the beginning. The Electronics PLI scheme is poised to place India in a global leadership position in electronics, and each success story reinforces that trajectory.

For more information, check out this Related video.

Frequently Asked Questions (FAQ)

Q1: What is the Electronics PLI scheme and its main objectives?

A: The Electronics PLI (Production Linked Incentive) scheme is a government initiative to boost domestic manufacturing of electronics, reduce imports, attract investments, create jobs, and develop integrated electronics supply chains in India.

Q2: How much investment and job creation has the Electronics PLI scheme generated?

A: The scheme has attracted over $7 billion in investments and created approximately 91,000 direct jobs across various electronics manufacturing sectors since its launch.

Q3: Which manufacturing sectors benefit most from the Electronics PLI scheme?

A: Key sectors include mobile phones, electronic components, wearable devices, semiconductor assembly, PCB assembly, and other electronics manufacturing segments.

Q4: Can you highlight some success stories under the Electronics PLI scheme?

A: Global mobile OEMs have expanded large-scale assembly lines in Tamil Nadu, Karnataka, and Uttar Pradesh, boosting exports worldwide. Component manufacturers like PCB fabricators have increased their capacity manifold, creating jobs and expanding exports to Southeast Asia and Europe.

Q5: How has the Electronics PLI scheme impacted India’s electronics exports?

A: Electronics exports have surged by over 30% year-on-year, aided by better pricing, faster delivery, and larger production volumes, enhancing India’s position as a global exporter of electronics.