Plastic waste recycling is a lucrative and crucial business opportunity in the current global environment. Plastic waste recycling is a lucrative business opportunity for startups and entrepreneurs interested in manufacturing and industrial ventures. This article explores the top 10 profitable business ideas for plastic waste recycling, analysing market trends, demand growth, and manufacturing processes. It offers a comprehensive guide to new entrants.

Plastic Waste Recycling Industry: Overview of the Market and Growth Potential

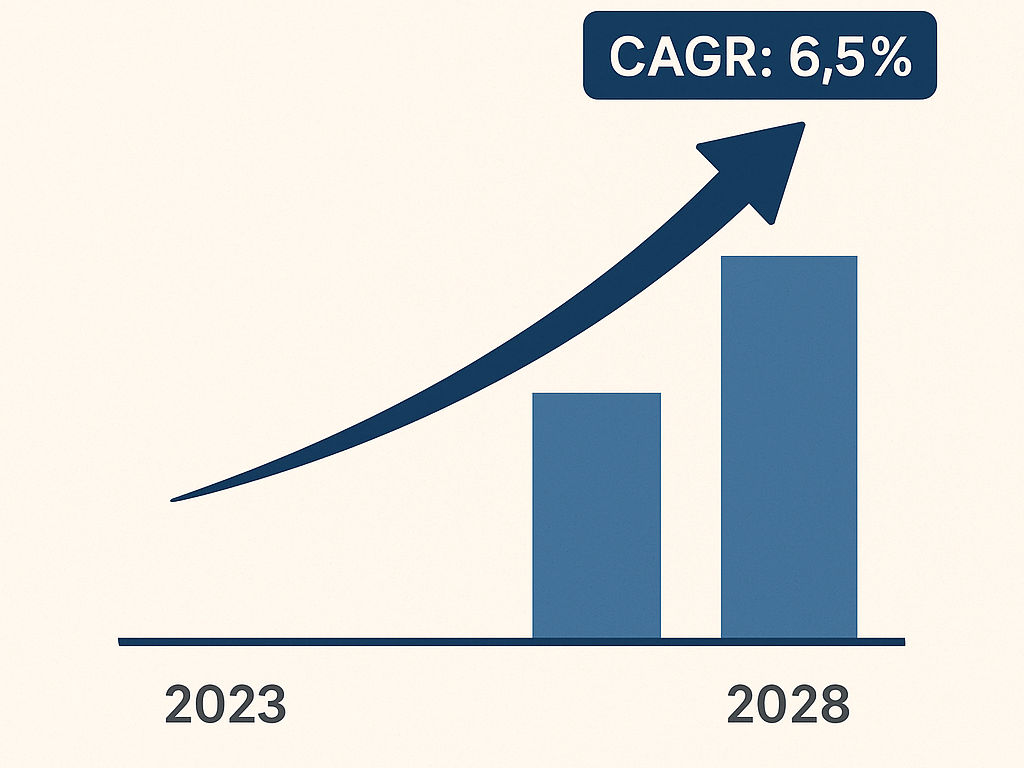

Plastic waste has increased exponentially over the past few decades due to an increase in plastic production. Governments, industries and consumers have been compelled to recycle because of the challenge in managing waste. The global plastic recycling market is estimated to be worth USD 40 billion by 2023. It will grow at a steady CAGR of 6.5% in the next five years. The key factors driving this growth are increased environmental awareness, tighter regulations on plastic disposal and the increasing use of recycled plastics by sectors such as packaging, construction and automotive.

In India and other countries, the rapid urbanization and increased plastic consumption, as well as government support via incentives and policies that encourage circular economy practices, are all contributing to the expansion of this industry. This creates an ideal environment for entrepreneurs to launch recycling businesses, which not only make profits but also contribute to sustainable development.

Related: Challenges and Opportunities in India’s Plastic Processing Industry

Why Recycle Plastic Waste?

Recycling plastic waste is a great way to protect the environment and create a business. Entrepreneurs who venture into this area play a crucial role in reducing pollution from plastic and conserving finite resources. The growing demand for recycled materials in multiple industries provides a steady income stream. The technological advancements in recycling and product quality have enabled new business models, from raw material recovery and manufacturing consumer and industrial products.

In addition, governments around the world are increasingly promoting recycling initiatives by providing an environment that is enabling with subsidies, tax breaks and market access. Plastic waste recycling is a profitable and sustainable business because of this confluence.

Detailed exploration of the top 10 plastic waste recycling business ideas

1. Recycling Plastic Waste into Granules

Plastic waste can be converted into pellets or granules, which is a profitable and fundamental recycling method. These granules are used as raw materials to make a wide range of plastic products. The first step is to collect and sort different types of plastics, such as HDPE (high-density polyethylene), PET (polyethylene terephthalate), and LDPE(low-density polyethylene). Mixing incompatible plastics will compromise the quality.

After sorting, plastics are thoroughly cleaned to remove contaminants such as dirt, adhesives, and labels. The plastic waste is then shredded into smaller flakes. The flakes are then extruded and melted through specialized machinery into uniform granules. The granules, which are then cooled and packaged to be sold to plastic manufacturers, can now be delivered.

The demand for recycled plastic granules continues to grow, particularly in industries such as those that produce containers, pipes and packaging films. The demand for recycled granules is increasing as more companies look to sustainable raw materials.

2. Plastic Waste Pyrolysis Oil Production

The Pyrolysis Technology offers a unique alternative by converting plastic waste to pyrolysis oils, which are a valuable substitute for conventional fossil fuels. This process involves heating waste plastic in an oxygen-free environment to cause it to thermally decompose into liquid oil and gas.

The pyrolysis reactor is filled with plastic waste that has been mixed and is difficult to recycle. Temperatures range from 350degC up to 500 °C. In the absence of oxygen, combustion is prevented. This allows for thermal degradation to hydrocarbon-rich oil. This oil can either be used as a fuel for industries or refined further to make diesel and gasoline.

Pyrolysis oil is a great business opportunity, especially with the focus on renewable energies and decreasing dependence on fossil fuels. The industries with the highest fuel consumption, such as manufacturing and transportation, are interested in adopting these alternatives. This indicates a strong market potential.

3. Plastic waste recycling into construction materials

The innovative niche of transforming recycled plastic waste to construction materials like bricks, tiles and panels is growing. These eco-friendly materials offer advantages like better insulation, durability and water resistance than traditional materials.

Sorting and shredding plastic waste into smaller pieces is the first step. The plastic waste is shredded and mixed with other building materials, such as cement, fly ash, or sand to create composite mixtures. The mixture is then formed into bricks and tiles by using extrusion or pressing equipment, before being cured in controlled conditions.

The construction industry is becoming more and more important, with an increasing focus on environmentally friendly building methods. This demand is driven by urban development projects, affordable housing programs, and green building certificates.

Related: Establishing a Plastic Waste Recycling Plant: A Comprehensive Guide

4. Recycling PET bottles into polyester fibers and fabrics

The high value of PET bottle recycling comes from the use of recycled PET fibers (rPET). These fibers are used in textiles and fabrics. This business converts PET bottles to polyester fibers that are used in the manufacture of clothing, upholstery and home furnishings.

To eliminate contaminants, the process begins with collecting PET bottles. The bottles are cleaned and shredded into small flakes. These flakes are then melted down into chips. These chips are spun into polyester fibers that can be woven into fabrics or yarns.

Demand for rPET fibres is driven by the global fashion industry’s move towards recycled and sustainable materials. Investing in this recycling route allows entrepreneurs to tap into the growing eco-conscious consumer base in apparel and home textiles.

5. Recycling Plastics to Produce Packaging Materials

Recycling plastic packaging is a profitable business because it’s one of the biggest consumers of plastic. It involves cleaning and collecting plastic waste and converting it to pellets. Then, using techniques such as injection molding, extrusion, or blow molding, the pellets are used to make packaging products like bottles, bags, containers, and films.

Many countries have banned the use of virgin plastics for single-use. Manufacturers are now actively searching for recycled alternatives to meet environmental regulations. This change opens up vast markets to startups that can provide quality recycled packaging, especially in the food and beverage sectors.

6. Making household utility products from recycled plastic

Plastic recycled from household items such as buckets, stools and mats can be used to create a variety of useful products. These products require plastic that is moderately durable and flexible in design.

Manufacturing involves sorting and cleaning waste plastics to remove impurities. The plastic is then melted to a workable texture and molded into different shapes with molds that are tailored to the specific product. The product’s appeal is enhanced by post-production finishing processes, like trimming and painting.

The demand for durable and affordable household products is a constant customer base, especially in developing countries with a growing middle class.

For more detailed information check our Project report on Waste Management, Waste disposal and Recycling Industry

7. Recycling Plastic for Automotive Components

In the automotive industry, recycled plastics are increasingly being used in components such as dashboards, bumpers and door panels. Manufacturers are motivated to reduce their carbon footprint and meet environmental standards.

This business relies on sourcing high-quality waste plastic, which is often sourced from scrap vehicles or industrial plastic. The plastic waste is then cleaned, processed into granules, or mixed with additives to meet automotive specifications. These granules can be molded into components using injection molding or compression molds. They are then subjected to rigorous testing for durability and safety.

The high-end market is technically challenging but also highly lucrative due to the premium prices and long-term agreements with OEMs and aftermarket suppliers.

8. Utilizing Plastic Waste in Road Construction

Recycling plastic waste is becoming a popular way to mix asphalt for road construction. By embedding plastic waste in infrastructure, this technique improves road durability and water resistance while reducing plastic pollution.

The plastic waste is shredded into small pieces, and then mixed with bitumen. Bitumen is used as a binder in road surfacing. The mixture of plastic and bitumen is used as asphalt to improve road strength while reducing maintenance.

To simultaneously address the plastic waste problem and the infrastructure challenge, several governments around world have adopted “plastic roads”. Entrepreneurs in this field can take advantage of government contracts and incentives for the environment.

9. Recycled plastic furniture manufacturing

Recycling plastics is increasingly being used in the manufacture of outdoor and indoor furniture, such as benches, tables, storage units, and chairs. These furniture items are durable, resistant to the weather, and environmentally friendly.

This process begins with melting plastic waste that has been cleaned and shred, and then extruding or molding it into furniture parts. The parts are then assembled and polished to improve aesthetic appeal.

Recycled plastic furniture is a lucrative business because of the growing awareness about environmental issues, as well as the demand for sustainable products, in parks, offices and homes.

10. Producing Agricultural Products with Recycled Plastic

Recycling plastics are used in agriculture for nursery pots and fencing. They can also be found in irrigation pipes. These products help to support sustainable farming by reducing the reliance on virgin materials and increasing resource efficiency.

The manufacturing process involves the sorting and processing of plastic waste to pellets. This is followed by extrusion, molding and forming durable agricultural products. To withstand the outdoor conditions, these products must meet certain quality standards.

Demand for these products is increasing as global attention turns to sustainable agriculture and water conservation. This presents entrepreneurs with a lucrative business opportunity.

View our Handbooks on Waste Management and Recycling, Industrial Waste Management

The Key Success Factors & Challenges

The plastic waste recycling industry is a lucrative business, but its success depends on a number of factors. It is important to have a steady supply of clean, segregated, plastic waste. This often requires partnerships with municipalities, waste management companies or community collectors.

The quality of the product and efficiency of operations are affected by adopting technologies and machines that are tailored to plastic types and final products. To meet industry standards, entrepreneurs must also understand regulatory requirements and invest quality assurance.

It is essential to establish reliable market links. It is important to build relationships with retailers, manufacturers, construction companies, and end users. This will ensure a steady demand for recycled products and prompt sales.

Environmental and Socio-Economic Impact

Plastic recycling companies contribute to the protection of the environment by diverting waste away from landfills and oceans. This prevents soil and water pollution. Recycling plastic uses less energy than virgin plastic production and reduces greenhouse gas emissions.

These businesses also create jobs at all stages of collection, processing, and manufacturing. They support livelihoods and promote inclusive economic growth.

Recycling is a great way for entrepreneurs to not only create profitable businesses but also promote sustainability and corporate responsibility.

For more information, check out this video

Conclusion

Plastic waste recycling offers diverse and profitable business options that balance economic goals with environmental sustainability. The sector provides multiple entry points, ranging from raw materials like plastic granules or pyrolysis oils to value-added products for construction, packaging and textiles to automotive and agricultural applications.

Entrepreneurs who are willing to invest in quality and maintain technology can take advantage of this sector’s growth while also contributing to the circular economy and plastic waste management goals.

Find Best Idea for Yourself With our Startup Selector Tool

About Niir Project Consultancy Services

Niir Project Consultancy Services is a specialist in preparing detailed techno-economic feasibility reports. The reports include descriptions of manufacturing processes, raw material requirements and plant layouts, as well as financial analysis. NPCS helps entrepreneurs and startups evaluate the feasibility of establishing a new industry or business, facilitating informed decisions and successful project implementation.