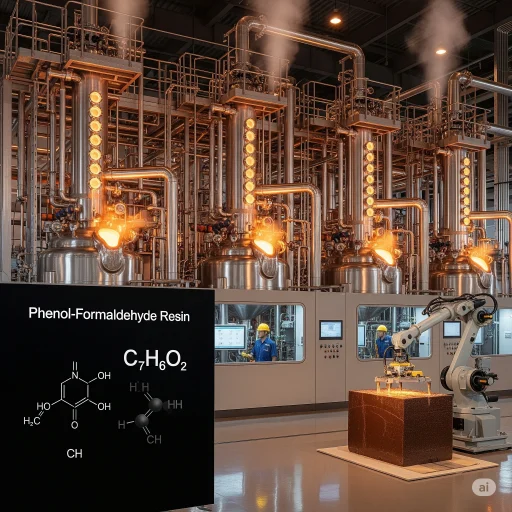

Phenol-formaldehyde (PF) resins are one of the most ancient and beneficial families that includes synthetic resins. They are used for strong adhesives, hard molds coatings that resist corrosion, as well as electrical components that are heat-resistant. The article I’ll explain the basics of what PF resins can be, how industries make them what they are, how they crosslink and cure, what features they offer and how they are processed by manufacturers and the precautions for safety and the environment you should make. I write in plain language and use simple sentences and provide concrete, technical information so that you can apply this knowledge to the production line or in the design of products.

What is the phenol-formaldehyde resin?

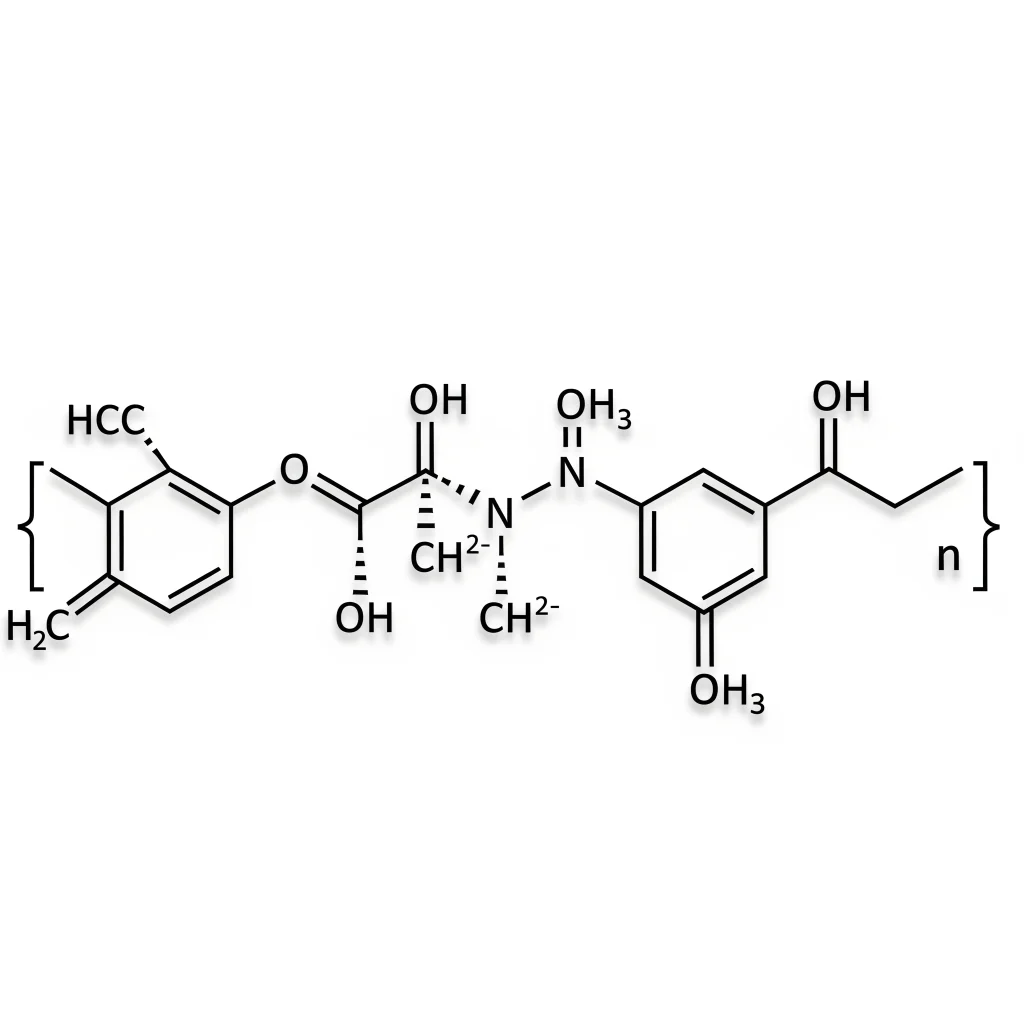

Phenol-formaldehyde is a type of polymer that is created by combining with phenol (a basic aromatic alcohol) with formaldehyde (a small aldehyde). Chemically, these two compounds react to form a network of phenolic rings that are joined through the methylene (-CH2–) and the methylene-ether (-CH2-O-CH2and methylene-ether (CH2-O-CH2) bridges. When the cure is completed the material is transformed into solid thermoset in three dimensions that is not able to melt or flow when heated.

Manufacturers create two major commercial classes:

- Resole (resol) resins are made from formaldehyde in excess and a base (alkaline) catalyst. These resins are self-curing upon heating.

- Novolac resins — made with excess phenol and an acid catalyst; novolacs remain thermoplastic until a curing agent (usually hexamethylenetetramine, abbreviated HMTA) converts them into a thermoset.

Below is a quick table of comparison.

| Feature | Resole resin | Novolac resin |

|---|---|---|

| Formaldehyde / Phenol ratio | > 1.0 (excess F) | < 1.0 (excess phenol) |

| Catalyst type | Alkali (NaOH, KOH) | Acid (p-toluenesulfonic acid Oxalic, p-toluenesulfonic acid) |

| State prior to cure | Liquid, self-curing upon heat | Thermoplastic solid, syrup or the like; requires a the help of a hardener |

| Common uses | Plywood adhesives, molding compounds | Molding, coatings, novolac + HMTA adhesives |

Read More: Solar Panel Manufacturing: Sunlight to Power

What industry processes are used to make PF resins – step-by-step

I’ll describe the two primary steps separately, as plants regulate the chemistry and processes in different ways.

Resole production (alkaline, excess formaldehyde)

- It is charged by the reaction. The plant mixes the phenol with an aqueous solution of formaldehyde (commonly 37-40 percent formalin) in an stirred stainless-steel reaction.

- Include catalyst. The operator adds the base in small amounts that is usually sodium hydroxide (NaOH) or potassium hydroxide (KOH) to increase pH into the range 8-10. The base accelerates electrophilic exchange within the aromatic rings.

- Control Molar ratio. Typical industrial F/P Molar ratios range from 1.1 and up 1.8, depending on the desired reactivity and free formaldehyde limitations. A higher F/P can cause faster-curing resoles, but it also increases the free formaldehyde.

- Hold and heat. The mix heats to moderate temperatures (60-95 degC) while condensation progresses. Operators monitor viscosity and free formaldehyde. The reaction time varies from just a few minutes to many hours.

- Cool and finish. The plant neutralizes or regulates pH, adding antioxidants and stabilizers as required, and then chills the resin until it reaches storage temperature. Resole resins typically contain water and can have 40% to 60 percent solids in commercial grades.

Want To Know About Which Business Idea Would Be Better For You?

Go Through Our Startup Selector Tool

Novolac production (acid and excess phenol)

- The charge reactant. The plant combines formaldehyde and phenol so that the F/P molar ratio is just below 1.0 (for instance 0.5-0.9.

- Add catalyst for acid. Typical catalysts include hydrochloric acid or p-toluenesulfonic. The acid encourages electrophilic transformation but also stops crosslinking.

- distill the water. Plants often run under partial vacuum or use heat to evaporate the water that is formed by condensation. This process will concentrate the resin and control its molecular weight.

- Recover and then finish. The novolac product usually is solid powder or syrup which is then milled and cooled by the producer. it. Novolac requires an agent for curing (HMTA) in later usage.

The reaction’s fundamental mechanism and reaction

Phenol has hydrogen atoms in the aromatic ring, which are reactive with formaldehyde. Formaldehyde is added either in the form of groups of hydroxymethyl (-CH2OH) as well as directly bridges to create Methylene (-CH2-) bonds between rings. Resoles have a base that is opened up by the phenol ring, which adds numerous hydroxymethyl groups. As you cook a Resole the hydroxymethyl groups combine to create crosslinks. In the case of novolacs, the reaction is stopped earlier, and produces short linear chains. You then add HMTA which releases formaldehyde with the heat and creates crosslinks.

How curing works practical cure for conditions

Curing is the process of transforming it into a solid and soluble network. The method of cure is dependent on the type of resin:

- Ressole resins The process is to heat them (typically 120-180 degC). At these temperatures, the hydroxymethyl groups begin to react with water leaves and the network is formed. The time to press is dependent on the parts’ thickness. Thin adhesive joints can cure within the span of a few minutes when press pressure and heat. the parts that are thicker require a longer curing.

- Novolac + HMTA: You mix novolac with hexamethylenetetramine (HMTA) and then heat. HMTA disintegrates and provides small formaldehyde pieces that link the phenolic chains. The typical cure temperature is 140-180 degrees Celsius. The pressure during molding assists in removing air trapped in the mold and compress fillers.

Be sure to follow the cure curves provided by your supplier since cure temperature and time determine the final crosslink densities, and this then determines mechanical strength and thermal behaviour.

Common formulations and add-ons

Manufacturers seldom make use of PF resin in its entirety. They often add pigments, fillers, and modifiers to control the cost and properties. Common components:

| Additive | Use and amount typical |

|---|---|

| Fillers (kaolin and calcium carbonate) | Reduce costs, manage shrinkage, increase stiffness (10-60 wt 10%) |

| Reinforcing fibers (glass, cotton) | Improve dimensional and strength (5-40 wt percent) |

| Plasticizers (phthalates are rarely are used) | Increase toughness a bit (small percentage only) |

| Extenders/thermoplastics (phenolic modifiers) | Adjust the brittleness and impact resistance. |

| Curing agent (HMTA) | Needed for novolac curing (5-15 phr in relation to resin) |

| Acid neutralizers or base neutralizers | Controlling the life of pots and stability |

| Pigments/dyes | Coloration of molded parts or coatings |

Formulators must are able to balance ingredients. Fillers that are too large can affect mechanical performance, while too small increases the cost.

Methods of processing — what factories and shops form the PF resins

Phenolic resins are widely used in the manufacturing process. The main processes are:

- The adhesive application is for laminates and plywood Resole adhesives are spread over veneers and then pressed under pressure and heat. Phenolic adhesives provide outstanding water-resistance and are suitable for external plywood.

- Transfer molding and compression -used for electrical components knobs, industrial fixtures. Operators warm the mold, insert the charge and then apply pressure at a temperature that is set until the mold is set.

- Impregnation, as well as lamination -paper or fabric that has been impregnated with phenolic resin then baked or pressed in order to create laminates (e.g. sheets of laminate sheets made of phenolic and printing circuit board substrates).

- Foundry binders and cores Certain systems made of phenol connect sand grains to facilitate coremaking They cure them later by catalysts or heat.

- Phenolic insulation and foams Special phenolic systems produce rigid foams with a low flammability to be used as construction insulation.

Each method requires its specific mold plan, pressure profile as well as a resin quality.

The key properties – what are the PF resins that offer you?

Below are a list of common property goals for cure polyphenolic resins as well as what they mean when used.

| Property | The typical behavior or benefit |

|---|---|

| High resistance to heat | Maintain strength even at high temperatures; Tg typically exceeds 130 degC. |

| Good dimensional stability | Low creep and minimal temperature expansion when under loads |

| Resistance to flame | Char, rather than melt Low inflammability |

| Chemical resistance | Resists many solvents and bases that are dilute. |

| Electrical insulation | Low loss and good dielectric strength in electrical parts |

| Brittleness | Formulators can be both stiff and brittle. Formulators include rubbers or fibers to make them tougher. |

Testing and quality control are part of the practice of the plant

The plants test both resin and the final components. The most common checks are:

- Content of solids — Determine by loss of drying time to regulate concentration.

- Viscosity Use a viscometer to regulate the flow of your application.

- pH — Critical for stability of resole.

- Gel time/pot life — Determine the speed of cure at a set temperature.

- No formaldehyde • Measure residual formaldehyde to determine security limits.

- DSC/TGA -Differential scanning calorimetry as well as thermogravimetric analysis to determine the thermal decomposition and cure behaviour.

- Testing for mechanical strength -Strength of flexural and tensile strength. Impact resistance determined on cured samples.

- Water absorption/boil test Particularly for adhesives made of plywood to conform to external standards.

Industry follows specifications from suppliers as well as the national standard for building and electrical installations.

Troubleshooting common manufacturing issues and problems

- Uncomplete curing The reason is low temperature, short duration or the improper hardener. Correct: increase the time or temperature of cure or include catalyst.

- Bubbles or blisters The cause is the trapped volatiles or excessive heating. Fix: preheat slowly, reduce volatiles, vent molds.

- Formaldehyde free of charge Cause: excessive formaldehyde or inadequate condensation control. Fix: decrease F/P ratio or post treat resin.

- Brittleness in the end It is due to high crosslink density, and no impact modifiable. Make sure to add rubber or fibers as modifiers.

- A weak adhesive The reason is the wrong type of resin or resin solids that are low. Solution: Use resoles specifically that are specifically designed for wood. Also, ensure that the spread rate is correct and adhere to the press timetable.

Read More: Build a Profitable EV Station Franchise: A Strategic Guide for New-Age Entrepreneurs

Handling, safety and environmental notes

Phenol as well as formaldehyde are both dangerous chemicals. Phenol is a skin irritant that can cause toxic effects on the system; formaldehyde is flammable and has been has been classified as a carcinogen for humans by the top agencies. Therefore:

- Make use of closed reactors as well as locally exhaust to collect the vapors.

- Put on PPE -goggles, gloves and respirators in areas where formaldehyde vapor could occur.

- Check the air quality in your workplace and observe the local exposure limits.

- Control resin-free formaldehyde in the final product by optimizing the reaction and post-treatment.

- Recycle waste responsibly Incinerate it within permitted facilities using appropriate scrubbers, or send it to certified chemicals waste treatment facilities. Do not add resin or solvents that are strong to drains.

Many companies use scavengers or post-curing procedures to reduce formaldehyde emissions from their finished products.

Read Our Book: Click Here

Recycling and end-of-life

Cured PF resins are resistant to heat and solvents, therefore mechanical recycling is difficult. The most common routes to end-of-life are:

- Energy recovery using controlled incineration by flue gas clean-up.

- The process of thermal depolymerization under specific conditions to extract fuel or energy.

- Filler material reuse following mechanical comminution for certain low-value applications.

Designers usually prefer to reduce the amount of PF used when recycling is a key feature of the product.

Related Article: Epoxy Resins Technology Handbook 3rd Edition

Common applications – concrete examples

- Marine and exterior wood adhesives – The PF adhesives hold veneers together during boil and weather tests.

- Molding materials and Bakelite-like parts – Switches electrical insulators, electrical switches, cooking handles.

- Brake linings, clutch faces – Phenolic binding agents made of fibers improve friction resistance and heat resistance.

- Phenolic laminates (paper/cloth) – Countertops and printed circuit boards (as variants of FR-2 or FR-4 usually use epoxy, but phenolic laminates are still used in a variety of industrial applications).

- Foundry sand binding agents – Produce sturdy Sand cores that withstand extreme temperatures.

- Phenolic foams – Rigid thermal insulation that provides excellent fire resistance in building and marine use.

Read Our Project Report: Click Here

Final thoughts

Phenol-formaldehyde resins provide outstanding thermal and chemical stability, as well as dimensional. Since they crosslink to form a solid network, they offer a durability and longevity even in the toughest of conditions. But, they require carefully controlled chemistry, safe handling of feedstocks that are hazardous, and a well-thought-out formulation to avoid excessive emissions or brittleness. If you choose the right grade, cure schedules as well as fillers, the PF resins are the most reliable material for molded parts, adhesives and high-performance composites.

FAQs – Phenol Formaldehyde Resin

Q What is the distinction between novolac and resole?

Resoles make up a solid, heat-curable resin that is made from excess formaldehyde as well as catalysts that are base. Novolacs are thermoplastic, phenol-rich prepolymers that require HMTA in order to set.

Q How hot should I cure the phenolic resin?

A Most cure times are between 120 to 180 degC The precise time of cure varies on the thickness of the formulation and its composition.

Q Can I use PF resin for outdoor plywood?

Yes. Phenolic adhesives are resistant to weather and water and conform to the standards for exterior grade plywood in the event that they are properly prepared.

Q What can I do to lower the emissions of formaldehyde in the panels?

Lower the F/P ratio, maximize condensation to use free formaldehyde, employ scavengers and post-curing actions to lock in free aldehyde.

Q What are phenolic materials recycled?

Cured phenolics are resistant to recycling. Industry typically recovers energy through controlled incineration or recycling crushed materials into fillers of low value.