Oxygen and Nitrogen Gas Production. Industrial Gas Plant

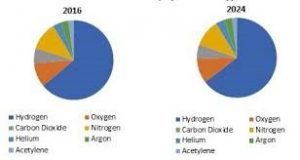

India industrial gases market forecast to grow at a CAGR of over 11%

Oxygen and Nitrogen Gas Production

Oxygen Gas

Oxygen and nitrogen are the most important industrial gases finding its application in large quantities in metal fabrication and cutting industries. It is used in electric arc steel furnaces for decarburization and scrap matting.

Oxygen is also used in medical treatment and for breathing at high altitude flying. Some quantities of liquid oxygen are used in explosives, chemicals and petrochemicals industries as an oxidizing and catalytic agent.

As the quantity of oxygen required in integrated steel plants is huge, the excess of oxygen is compressed and bottled in steel cylinders and supplied to engineering industries such as manufacture of machine tools, industrial machinery, automobiles and component manufacturers, fabricators of chemical plants, storage tanks, and furniture and building elements.

Nitrogen Gas

Nitrogen is a colorless, odorless, inert and non-flammable gas. Although it is inert in nature, it reacts with other compounds under specific conditions. Industrial Nitrogen has a varied range of application in different industries. Nitrogen gas is used in the production of ammonia which in turn is used for the manufacture of urea and ammonium phosphate, which are fertilizers of great use. Nitrogen gas is used for blanketing hazardous chemicals which is an inert atmosphere.

Nitrogen gas is used for purging purposes. Nitrogen gas is used for the purification of other gases with extremely low boiling points, such as hydrogen scrubbing. High purity nitrogen is used in strip steel annealing prior to tin plating.

Human blood and cattle sperm cells are pressured by using nitrogen liquid freezing method. Large quantities of liquid nitrogen are employed in the preservation of food by rapid freezing. Liquid nitrogen is also used to maintain low temperatures during the transportation of frozen food. The demand of oxygen and nitrogen gas will increase in future

Uses:

Oxygen gas

- Oxygen is also used in many industrial, commercial, medical, and scientific applications. It is used in blast furnaces to make steel, and is an important component in the production of many synthetic chemicals, including ammonia, alcohols, and various plastics.

- The steel industry also uses oxygen gas in an oxy-acetylene flame, for scale removal from billets, and in oxygen lances, for cutting out imperfect ions.

- The continuous gasification of coal or other solid fuel, oxygen gas admixed with steam is passed into the fuel bed and maintains a sufficiently high temperature to allow the waleragas reaction to proceed smoothly.

- Oxygen gas is used in hospitals (to enrich air in respirators and to mix with anesthetics), aviation (for pilots’ air supply), and pollution control. The space program was a major user of oxygen,

- In the chemical and petrochemical industries, as well as in the oil and gas sector oxygen is used in commercial volumes as an oxidizer in chemical reactions. The use of oxygen in gas-flame operations, such as metal welding, cutting and brazing is one of the most significant and common applications of this gas.

Nitrogen Gas

- Nitrogen is used primarily as a freezing agent and a blanketing agent. About 21% of nitrogen produced is used for freezing

- Other freezing applications include cryogenic size reduction of plastics, rubber, spices, and pharmaceuticals. About 33% of all nitrogen produced is used for blanketing, mostly in chemical processing and the electronics industry (14% each), with some application in the primary metals industry (5%).

- Demand for nitrogen has been growing steadily 1n the liquefied industrial gases market and the chemical industry. In the aluminum industry, nitrogen has been replacing inert gas generators. The enhanced -oil products industry also requires fairly large quantities of gaseous nitrogen.

- Nitrogen requirements for steel manufacture are modest and seldom exceed a small fraction of the oxygen flow. Some nitrogen~lso is used as the principal refrigerant in air separation cycles and as clean-up gas (to remove unwanted carbon dioxide and water).

- Chemical Plants – Nitrogen is used to displace oxygen and prevent explosions in highly dangerous atmospheres, such as chemical plants and manufacturing facilities. Tire Inflation – Nitrogen offers many benefits when used to fill tires, such as giving them a longer life by reducing oxidation

- Food Packaging – Nitrogen is used to displace oxygen in food packaging. By eliminating the oxygen, the food can last longer. It can also add a cushion around the food to keep it safe from breaking in transport.

- Light Bulb Production – In incandescent light bulbs, nitrogen gas is often used as a cheaper alternative to argon.

- Chemical Plants – Nitrogen is used to displace oxygen and prevent explosions in highly dangerous atmospheres, such as chemical plants and manufacturing facilities.

- Tire Inflation – Nitrogen offers many benefits when used to fill tires, such as giving them a longer life by reducing oxidation. It also improves tire pressure retention to give drivers better gas mileage.

- Electronics – When electronics are being assembled, nitrogen gas is used for soldering. Using nitrogen reduces the surface tension to provide a cleaner breakaway from the solder site.

- Stainless Steel Manufacturing – By electroplating the stainless steel with nitrogen, the finished product is stronger and resistant to corrosion.

- Pollution Control – Nitrogen gas can be used to remove the VOCs in liquids before they are discarded.

- Pharmaceuticals – Almost every major drug class contains some nitrogen, even antibiotics. Nitrogen, in the form of nitrous oxide, is also used as an anesthetic.

- Mining – In the mining industry, nitrogen gas is used to quickly extinguish fires by eliminating the oxygen from the air. And when an area is going to be abandoned, they use nitrogen to ensure the area will not explode.

- Mild steel & carbon steel annealing

- Electronic industries like semiconductors etc.

- Blanketing during chemical reactions

- Auto industries for Sintering, Brazing & Soldering

- Food packaging

- Tire filling

- Metal powder formation

Market Outlook

The medical gases market size in India, in volume terms, is forecast to witness a two folds increase by 2019, exhibiting a CAGR of about 15% during 2014-19.

The medical gases market in India is highly dominated by region-specific players, which are offering a stiff competition to multinational companies. India’s specialization in cardiology, orthopedic surgery, etc., is expected to drive healthcare demand, particularly for medical oxygen and nitrous oxide, which are vital requirements of any healthcare setup. Currently, the northern region, followed by the southern region, is the leading demand generators for medical gases, particularly medical oxygen gas.

Oxygen

| Demand : Past and Future | |

| Year | (In Million m3) |

| 1990-91 | 450 |

| 2000-01 | 1335 |

| 2001-02 | 1525 |

| 2002-03 | 1725 |

| 2003-04 | 1975 |

| 2004-05 | 2315 |

| 2005-06 | 2760 |

| 2006-07 | 3360 |

| 2007-08 | 3730 |

| 2008-09 | 4910 |

| 2009-10 | 5400 |

| 2010-11 | 6250 |

| 2011-12 | 7210 |

| 2012-13 | 8200 |

| 2013-14 | 9165 |

| 2014-15 | 10000 |

| 2015-16 | 11250 |

| 2016-17 | 12800 |

| 2017-18 | 13950 |

| 2018-19 | 15700 |

| 2019-20 | 17230 |

| 2024-25 | 27125 |

Global Oxygen Market: Overview

Oxygen is a colorless gas which is a paramount factor to sustain life. Oxygen is available in cylinders, containers, and cans. They are mostly used for industrial, medical, and scientific applications. Oxygen is used as an oxidizing agent and as a catalyst in various scientific and industrial processes. The oxygen market is growing at a significant pace and the growth in the oxygen market has resulted in an increase in the related markets such as medical oxygen generators, air-oxygen blenders, and stationary and portable oxygen concentrators.

The global oxygen market is divided into its form, application, end-users, and geography. On the basis of a form of oxygen, the market is segregated into solid, liquid, and gaseous. Based on application, the market is classified into cosmetics, pharmaceutical, automobiles, and mining and mineral processing applications. On the basis of end-users, the market is categorized into industrial, medical, and scientific sectors. Diversification of the market on the basis of the region is seen into Asia Pacific, North America, Europe, Latin America, and the Middle East and Africa.

Global Oxygen Market: Regional Analysis

The largest share in the oxygen market is held by the Asia Pacific region. This growth can be attributed to reasons such as the growth of manufacturing sector and healthcare. Also, growth in the mineral and mining processing, where oxygen is a key catalyst, helps in the expansion of oxygen market in the region. Regions such as China, Japan, India, Australia, and New Zealand are showing major contribution in the Asia Pacific market.

Global Oxygen Market

Industrial Nitrogen Gas Market

The market is witnessing a rise in demand from the food and beverages market. Its freezing property has expanded its use in blood banks, cryogenic treatments and plastic and rubber industries. Demand from end-users such as metal manufacturers, chemical and transportation industries are also propelling the industry to grow.

Application wise its use can be segmented into metal manufacturing, oil and gas sector, petrochemical, pharmaceutical and healthcare, chemical, food and beverage industry and electronics. Food packaging – to displace the Oxygen from packaging that helps the food product to last long, used as fertilizer when combined with Ammonia to form Nitrates, Tire Inflation – by improving life of the tire and getting better mileage.

The demand for industrial gases also continued to remain strongly driven by an increase in investments in infrastructure development and petroleum reserves in emerging markets. In fact, metal fabrication and production sector are expected to remain the second major sector for industrial gases, next to petroleum refining.

Over the longer term to 2022, the annual growth rate in the industrial gas market is expected to significantly exceed the rate of industrial production driven by multitude of factors including opening of new startups, rapid industrialization of emerging economies, increasing demand for energy, environment regulations, improving healthcare sector, and advancements in industrial technology.

Key Players

- Hale Hamilton

- Maximator GmbH

- Hydrotechnik UK Ltd

- HyDAC

- Hydraulics International

- Inc

- Accudyne Industries

- Semmco Limited among

See more