Ever thought about the golden liquid that you pour in your frying pan before? The bottle of olive, sunflower, or soybean oil in your kitchen is the result of a long journey. This is a fascinating story that begins in a farmer’s field and ends up with a complex manufacturing process.

Oil is simply fat that is liquid when it is at room temperature. Oil is obtained from plants by squeezing the oil out of their fruits, seeds or nuts. It’s not as easy as just squeezing. Cleaning, pressing, purifying and testing are all necessary to ensure the product is safe and tasty. Do you want to star your oil manufacturing business? Then read along.

Oil Manufacturing: The Journey from Seed to Bottle

The transformation from a raw plant material into the clear, pure oil we use is a multi-step process. While the exact steps can vary depending on the type of oil, the general path is quite similar for most common cooking oils.

Step 1 Of Oil Manufacturing: Getting The Raw Materials

Farmers grow the plants and trees that give us oil. The oil’s quality depends on how good these plants are.

- Oilseeds: Companies use seeds like sunflowers, rapeseed (that’s canola), soybeans, sesame, and cottonseed to make oil

- Fruits: Some fruits have lots of oil. Olives and coconuts are the most popular. They use the fruit’s flesh, not the seed inside

- Nuts: People also press nuts like peanuts, almonds, and walnuts to get oil

Workers harvest these seeds, fruits, and nuts. Then, they send everything to the oil mill.

Related Article: Investment Opportunities in Business of Essential Oil from Lemon Grass.

Step 2 Of Oil Manufacturing: Cleaning The Area And Preparing For The Squeeze

It’s not enough to throw in dirty seeds. First, a thorough clean is required. The seeds or fruit are then passed through magnets and screens to remove unwanted particles such as dirt, stones, leaves and metal.

Preparation begins after cleaning. It is important to do this step if you want the maximum amount of oil.

- De-hulling: The outer shell, or “hull”, is removed from many seeds like sunflowers or soybeans. The hull is very low in oil and will absorb whatever you are trying to extract.

- Grinding: The seeds are cleaned and de-hulled, then ground to a coarse meal. The tough plant material is broken down and the oil-bearing cell membranes are ruptured. This might require cracking larger seeds in a roller-mill.

- Cooking: The meal is heated gently in cookers. It’s not about cooking a dish; this is a strategy. The heat breaks down the cell walls, making it easier to remove the oil. This step increases the amount you can extract.

Step 3: Extraction of Precious Oil

The oil is extracted from the meal at this stage. There are two main methods used: mechanical extract (pressing), and solution extraction.

Want To Choose Best Business Idea At Your Specific Budget?

Here Is Our Startup Selector Tool To Help You With this

Mechanical Extraction – The Power Of The Press

It is the simplest and oldest method. This is exactly what it says: Manufacturers squeeze oil out of meal by applying immense physical pressure.

Cold Pressing: This method extracts the oil without any additional heat being added during the pressing process. The temperature is kept low, typically below 49degC. This gentle process preserves the oil’s natural aroma, flavour and nutrients.

Cold-pressing is used by manufacturers to make extra virgin oil, an example of a classic. This method is not as efficient, and it leaves behind a lot of oil in the leftover meal.

Hot Pressing: In order to extract more oil, manufacturers heat prepared meal at a higher temperature and then feed it into a powerful press. The expeller is a machine that uses a rotating shaft to force the meal continuously through a barrel.

The oil is squeezed out of the barrel through tiny openings. The method is more efficient than cold pressing, but it can change the oil’s color, taste and nutritional profile.

Step 4 Of Oil Manufacturing: Solvent Extraction – Washing Out The Oil

Pressing alone won’t work for seeds like soybeans that have a lower oil content. Solvent extraction, a chemical process that is highly efficient, allows manufacturers to extract almost all of the oil.

How do they do it? Manufacturers “wash” prepared seed flakes in a solvent. Most commonly, this is a food grade substance, it is popular as hexane. Hexane dissolves oil very well. The hexane is poured over the flakes and pulls the oil from them.

The mixture is oil and hexane. This process removes oil from the solid leftover meal. Do not worry about the chemical. In the next step, the manufacturers heat the oil and hexane mixture carefully. In the extraction process, hexane, which has a lower boiling point than oil, vaporizes.

The system collects this vapor and reuses it, leaving behind the pure oil. This method is so efficient that less than 1% of the oil remains in the meal. The meal is often processed into animal feed by manufacturers because of its high protein content.

Read Our Book ‘Emerging Investment Opportunity in Edible Oil Industry in India‘

Refine The Oil For Purity And Stability

You can’t use the oil until it manufacturers extract it. They usually blast it with heat or soak it in chemicals. They refer to this oil as “crude” oil due to the impurities it contains, which can affect its smell, taste, appearance, and shelf life. This marks the beginning of the refinement process.

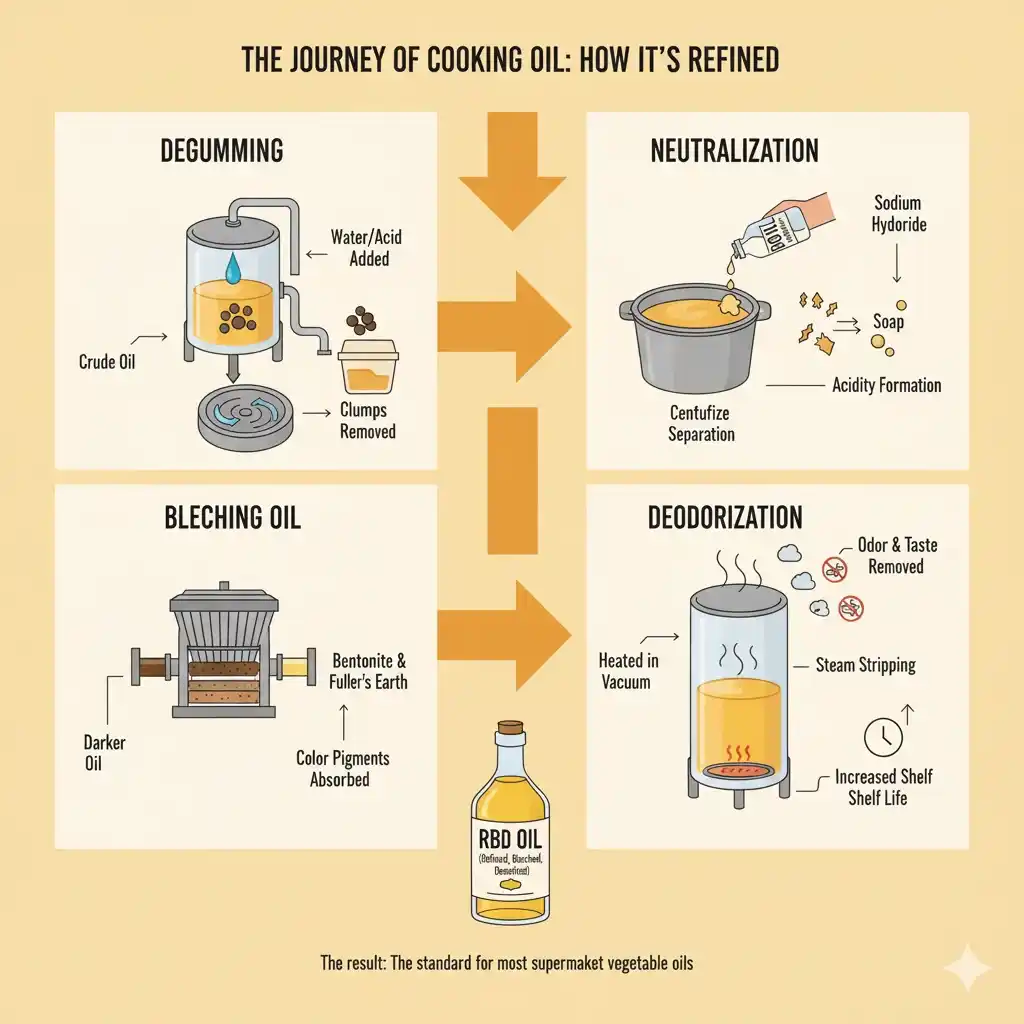

Manufacturers refine their products in a multi-stage process.

Degumming: First the manufacturers mix crude oil with water or acid. The phospholipids, and other gummy substances will clump up. A centrifuge can easily spin and separate these clumps.

Neutralization: Crude oils contain free fatty acid, which can cause them to smell soapy and go rancid very quickly. Manufacturers add an alkaline substance like sodium hydroxide to fix this. The alkaline substance reacts to the free fatty acid to form soap. This reduces the acidity of the oil.

Bleaching Oil: It may still contain colour pigments. Manufacturers filter the oil through bentonite and fuller’s Earth to create a clear, light-colored oil. These clays absorb colour pigments and make the oil lighter.

Deodorization: It is the last and most important step in refining cooking oil to make it neutral. The manufacturer heats the oil to a high heat under vacuum, and then steam is passed through. This process is “steam stripping” and removes any substances that may give the oil a bad taste or odor. This process also increases the shelf life of oil.

The industry refers to this oil as RBD Oil. This is the standard for the majority of vegetable oils that you can find at the supermarket.

Related Article: Potato Chips and Snack Food Setup Manufacturing Business

Step 5 Of Oil Manufacturing: Final Checks And Packaging

Now the oil is ready. Before it reaches you, it must pass strict quality tests. The technicians check the color, taste and purity of the product, as well as its free fatty acids, to ensure that it meets safety standards.

After approval, technicians pump the oil in storage tanks. Then onto a bottling machine. After extraction, manufacturers pump the oil into bottles, cans, or other containers. This is the time to label and package the oil bottles into cartons to reach the globe.

Read Our Project Report On Edible Oils Projects

Oil Manufacturing: Conclusion – An Everyday Marvel

Now we understand that cooking oil’s manufacturing journey is a blend of science and nature. The journey of cooking oil begins with a simple seed. It then goes through a series carefully controlled steps, including cleaning, grinding, pressing and extracting.

Next time you pour some oil in a pan, appreciate the amazing manufacturing feat that brought it into your kitchen. This is a process that aims to produce the best product possible, making food more delicious and our lives easier.

Oil Manufacturing: Frequently Asked Questions (FAQs)

Q1: What’s the difference between refined and unrefined oil?

A: Unrefined oils keep their natural taste and color. They have more nutrients but go bad faster and can’t handle high heat. That’s why manufacturers cleans up Refined oils to last longer and work better for frying.

Q2: Is cold-pressed oil healthier?

A: Cold-pressed oils have more vitamins and antioxidants. They’re good for salads. For frying, use refined oils so the oil doesn’t burn.

Q3: What is a smoke point and why does it matter?

A: Smoke point is when oil starts to smoke. If it smokes, the taste and nutrition get worse. Use high smoke point oils for frying. Use low smoke point oils for dressing or low heat.

Q4: Is the hexane used in solvent extraction safe?

A: Yes. The Manufactures remove Hexane during processing. The oil is safe to eat.

Q5: How is oil manufacturing becoming more sustainable?

A: Factories save energy and water. Leftover seeds become animal food. Some oil comes from farms that help the environment.