Organic manure, also known as organic fertilizer, compost, or vermicompost, based on the method used, is becoming more appealing to farmers, landscapers, and environmentally conscious consumers. For entrepreneurs and startups, producing organic manure provides a scalable and accessible way to enter the agricultural inputs sector while supporting sustainability trends.

Market forecasts predict consistent growth in the organic fertilizers sector over the next decade, fueled by increased adoption of sustainable agriculture and rising consumer interest in organic products. In India, demand is boosted by government programs that support natural and organic farming, growing consumer preference for organic products, and farmers’ increased focus on soil health.

Demand Drivers and Target Customers

Key market drivers include growing interest in soil health and regenerative farming practices, rising consumer demand for organic and premium produce, and increased availability of municipal and agricultural organic waste for feedstock. Primary customers to target are smallholder and commercial farmers, organic farms, nurseries and landscapers, garden retailers, and municipal or institutional buyers seeking eco-friendly soil amendments.

Types of Organic Manure and Product Positioning

Decide early on which product formats you will focus on, as each needs different processes and marketing. Common formats include bulk compost for farms and landscapers, vermicompost (worm castings) for premium markets, and blended or value-added mixes (for instance, combined with minerals or microbial inoculants) that target specific crops or retail gardeners. Your plant design, equipment, and marketing strategy will vary according to these choices.

Detailed project report on organic manure

Manufacturing Process — Practical Outline

Feedstock Sourcing and Characterization

Secure reliable sources such as agricultural residues, animal manures, food processing by-products, yard trimmings, or municipal green waste. Inspect incoming materials for moisture, contaminants, and the carbon-to-nitrogen balance to ensure consistent process performance.

Pre-processing and Blending

Shred or chop materials to reduce particle size and speed up decomposition. Mix high-carbon and high-nitrogen materials to achieve the desired C: N ratio and remove non-organic contaminants at entry.

Primary Biological Conversion

Select a composting method that fits your land, capital, and throughput needs. Options include open windrows with periodic turning, aerated static piles with forced airflow, and in-vessel systems for faster processing. A common practical approach is to use thermophilic composting for pathogen reduction, followed by vermicomposting to enhance the material’s biological quality.

Curing and Maturation

Allow material to stabilize and humify after the active phase. Curing minimizes odors and further stabilizes nutrients, producing a better, longer-lasting product.

Screening and Post-processing

Screen the finished material to remove coarse particles and contaminants. Depending on your market, you can dry, pelletize, or mix the compost into specialty blends for retail.

Quality Control and Testing

Run routine tests for moisture, pH, electrical conductivity, nutrient content, and pathogen indicators. Keep detailed batch records for traceability and certification.

Packaging and Distribution

Package in formats that suit customer needs: bulk deliveries for farms and smaller bags for retail. Provide clear labeling with composition, application guidance, and batch identification. Build distribution through agricultural dealers, nurseries, online sales, and direct farm deliveries.

For in-depth insights, see our books.

Vermicomposting Versus Aerobic Composting — Practical Notes

Vermicomposting produces nutrient-rich worm castings valued for their microbial content, but it requires careful feedstock preparation and controlled temperature conditions. Aerobic thermophilic composting is generally easier at larger scales and is effective for pathogen reduction. Many successful operations combine both methods: use thermophilic composting for initial stabilization and then vermicompost the material to improve its biological value.

Equipment and Layout Considerations (High Level)

Necessary equipment includes shredders and mixers for pre-processing, compost turners or aeration systems for conversion, beds or troughs for vermiculture, and screens and pelletizers for post-processing. Design the facility to allow a single-direction flow from raw feedstock to finished products, and physically separate raw and finished materials to prevent contamination.

Quality, Certification, and Regulation

If you target certified organic farms, follow the relevant national organic standards and keep accurate records of inputs and processes. Control leachate, odors, and pests through good site design and process management. Clear nutrient labeling and application guidance will help build customer trust and reduce misuse.

Market Positioning and Go-to-Market Tips

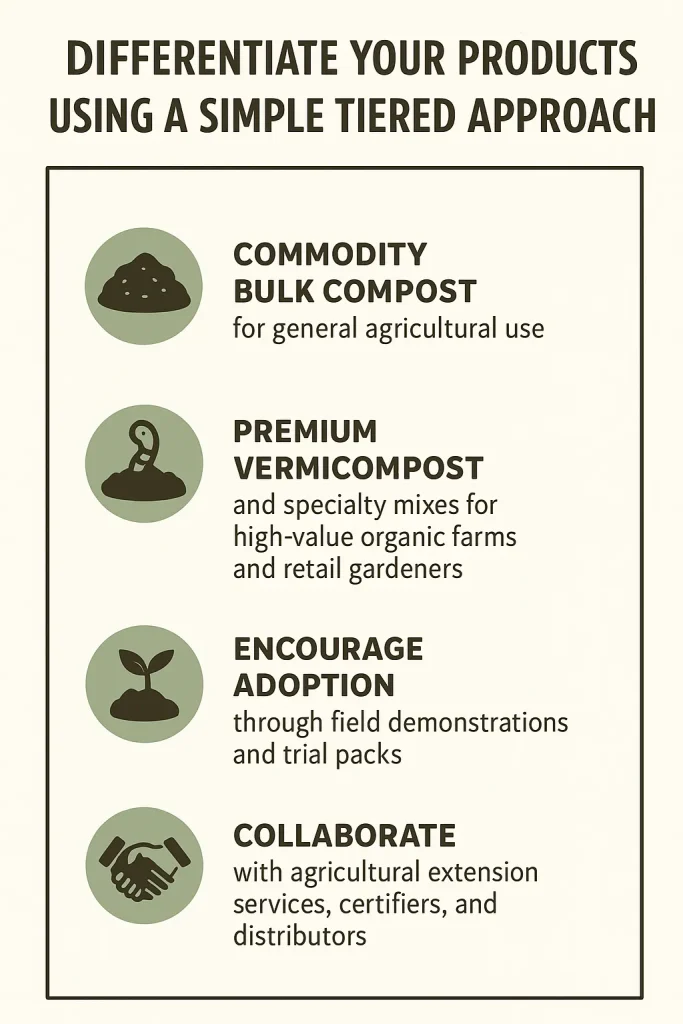

Differentiate your products using a simple tiered approach: commodity bulk compost for general agricultural use and premium vermicompost and specialty mixes for high-value organic farms and retail gardeners. Encourage adoption through field demonstrations and trial packs, and collaborate with agricultural extension services, certifiers, and distributors.

Content that explains product benefits and use cases will attract both retail and direct farm customers. Securing feedstock contracts with municipalities or processors can ensure a long-term supply while strengthening sustainability credentials.

Sustainability, Circularity, and Branding

Converting organic waste into compost is inherently sustainable and can lessen landfill waste and related emissions. Promote the benefits to soil and the circular model transparently, backing up claims with third-party lab tests or certifications rather than broad, unverified climate assertions.

Common Risks and Mitigations

Feedstock variability: maintain ties with multiple suppliers and test incoming batches.

Odor and pests: keep aerobic conditions and buffer zones in place.

Contamination from plastics or heavy metals: Use thorough manual sorting and prefer clean industrial or agricultural feedstocks.

Market competition: stand out through measured product quality, agronomic support, and dependable logistics.

Related articles:- PROM Fertilizer: Unlocking the Potential of Soil with Phosphate-Rich Organic Manure

Operations and Staffing

Critical operational roles include a plant manager with composting knowledge, a quality-control contact for testing and certification, and agronomy or sales staff to conduct trials and support customers. Provide basic training on process control, biosecurity, and worker safety.

Scaling and Innovation

Consider creating crop-specific blends, adding beneficial microbial inoculants, securing long-term contracts for municipal feedstock, or using IoT monitoring for process improvement. These enhancements can increase margins and strengthen customer loyalty.

Market Forecast Summary

Market data consistently shows steady growth in the global organic fertilizers sector, with regional markets like India experiencing strong demand due to organic farming initiatives and consumer interest in healthy food. For startups, the combination of rising demand and available feedstock offers an attractive opportunity for local production.

Practical Checklist for Entrepreneurs (Quick Reference)

- Decide on your product focus: bulk compost, vermicompost, or blends.

- Secure feedstock sources and start with a small pilot to validate processes.

- Implement basic quality systems and testing.

- Build distribution through dealers, nurseries, direct farm sales, and online channels.

- Ensure permits and certifications are in place if needed.

About Niir Project Consultancy Services (NPCS)

Niir Project Consultancy Services (NPCS) prepares tailored Market Survey and Techno-Economic Feasibility Reports for entrepreneurs and industry newcomers. Their reports include detailed manufacturing processes, raw material lists, and plant layout sketches. NPCS helps entrepreneurs evaluate the feasibility of starting new businesses by combining market analysis with practical project planning.

Conclusion

Organic manure production is at the crossroads of sustainability and agriculture. Entrepreneurs who prioritize consistent product quality, practical agronomic messaging, dependable feedstock sources, and compliant operations can build strong businesses. Begin with a pilot, collect field data and customer feedback, then expand into premium blends and wider distribution. With rising demand and supportive circular models, this area offers a promising space for purpose-driven ventures.

Use our startup selector tools to discover the best business ideas for you

Frequently Asked Questions

What is organic manure?

Organic manure is a natural fertilizer derived from plant and animal waste that improves soil fertility and enhances crop yields.

Why is organic manure manufacturing a good business?

Rising demand for sustainable agriculture and chemical-free farming makes organic manure a profitable and eco-friendly venture.

What are the key raw materials required?

Raw materials include crop residues, animal dung, green leaves, kitchen waste, and other biodegradable organic matter.

What is the market outlook for organic manure?

With increasing awareness of soil health and organic farming, the organic manure market is expected to grow steadily worldwide.

How does NPCS help entrepreneurs in this sector?

NPCS provides techno-economic feasibility reports, including manufacturing processes, plant layout, and financial analysis, to help entrepreneurs assess business viability.