Pesticides are essential in modern agriculture; they protect crops from pests, diseases, and weeds. Their use has greatly boosted agricultural productivity and ensured food security for millions globally. As the population grows and agricultural land becomes limited, the demand for pesticides keeps increasing. This trend presents significant opportunities for those looking to start a pesticide manufacturing business.

Importance of Pesticides in India

India, one of the largest agricultural economies, leads in pesticide use and production. The country’s varied climate makes crops susceptible to many pests, increasing the dependence on crop protection chemicals. Additionally, a growing awareness of better farming practices has driven the need for effective, safe, and affordable pesticides. For entrepreneurs, this means a large and steadily growing market.

Detailed project report

Market Overview for Pesticides

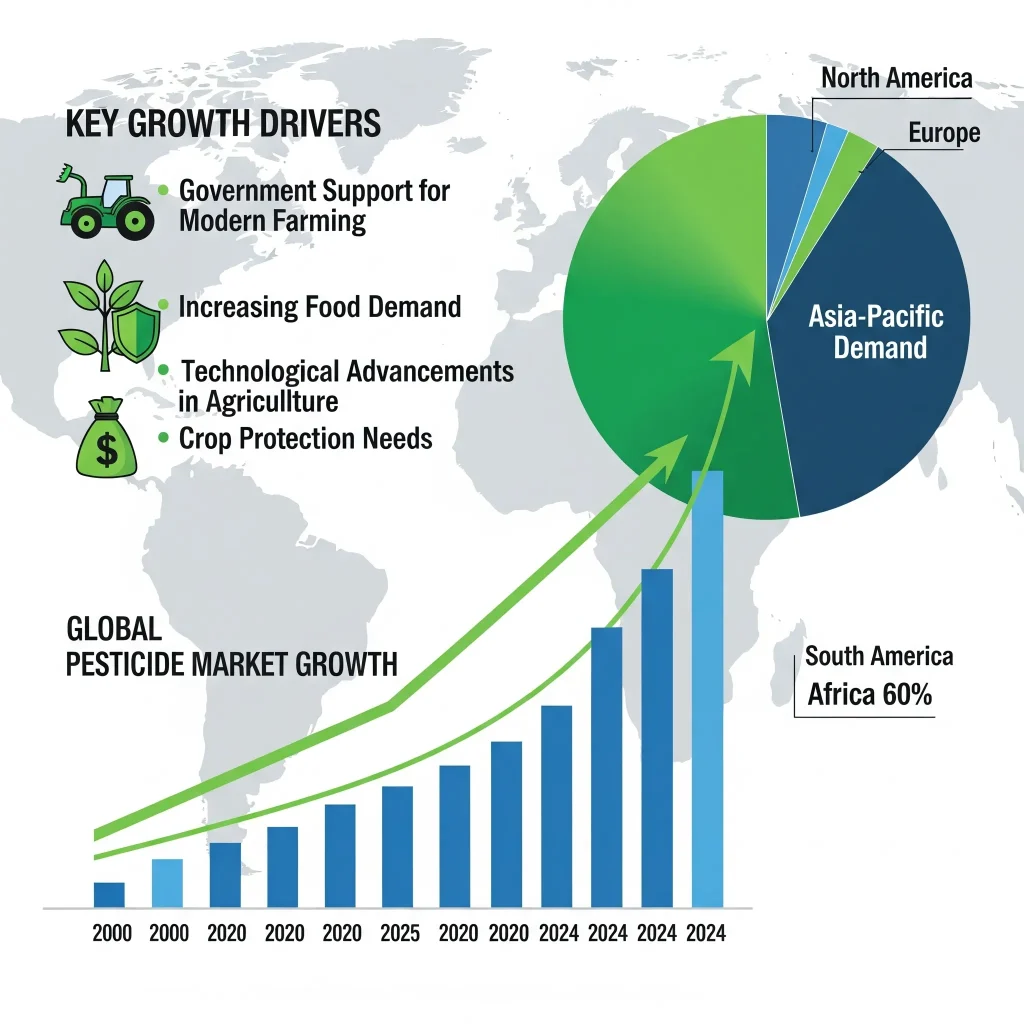

Worldwide, the pesticide market is valued at billions of dollars and continues to grow consistently. The Asia-Pacific region, especially India and China, makes up a large portion of this demand. With the government encouraging modern farming techniques and aiming for higher agricultural productivity, the domestic pesticide market is expected to stay robust.

Pesticides include insecticides, herbicides, fungicides, and rodenticides, with each serving a specific function. Entrepreneurs can either specialize in one category or produce a range of products to meet various farming needs. The rising trend towards organic and bio-based pesticides also opens up new avenues for innovation.

To explore more, check our books

Steps in Starting Pesticide Manufacturing

Starting a pesticide manufacturing business requires thorough planning and adherence to strict regulations. The first step is obtaining the necessary licenses and approvals from government agencies, as pesticides are closely regulated due to their potential health and environmental impacts. Entrepreneurs need to establish a modern production facility with the right machinery, quality control systems, and safety protocols.

Manufacturing typically involves selecting active ingredients, formulating, mixing, and packaging the products. Quality assurance is crucial because even small mistakes can lower effectiveness or create safety issues. Hiring qualified chemists and investing in lab facilities is vital. Proper waste management and compliance with environmental standards are equally important for social responsibility.

Related articles:- How to Start an Adjuvants for Pesticides Manufacturing Business?

Investment and Profitability

The initial investment in pesticide manufacturing can be substantial due to machinery costs, raw materials, and regulatory approvals. However, once the business is established, it can be very profitable. Growing demand from farmers and increasing exports can lead to significant returns on investment. Entrepreneurs can also consider contract manufacturing or forming partnerships with established companies to lessen entry obstacles and access the market.

The potential for exporting pesticides is particularly appealing. Countries in Africa, South America, and Asia import large amounts of crop protection chemicals. Indian manufacturers, with their cost advantages and expertise, are well-positioned to seize these opportunities.

How NPCS Helps Entrepreneurs

NIIR Project Consultancy Services (NPCS) offers comprehensive support for entrepreneurs starting pesticide manufacturing. They provide feasibility studies, project reports, regulatory advice, and market analysis to help businesses prepare for the sector’s challenges. Their expertise assists entrepreneurs in selecting the right product mix, identifying target markets, and implementing efficient manufacturing methods.

NPCS also helps with securing necessary certifications, crucial for domestic and export sales. By using their experience, entrepreneurs can reduce risks, streamline processes, and build sustainable pesticide businesses.

Conclusion

The pesticide industry offers great potential for entrepreneurs willing to invest in a highly regulated yet rewarding field. With increasing agricultural demand, heightened awareness of crop protection, and strong export chances, pesticide manufacturing promises long-term growth and profitability. Success hinges on maintaining product quality, ensuring compliance, and keeping up with market trends.

With guidance from NPCS, entrepreneurs can navigate the challenges of regulation, investment, and technology to launch successful businesses. As agriculture evolves, pesticides will stay vital for food security, making this industry a significant opportunity for the future.

Discover the best business ideas for yourself using our startup selector tools

Frequently Asked Questions

What are the key regulatory requirements for starting a pesticide manufacturing business?

The regulatory requirements for starting a pesticide manufacturing business are very strict. You must obtain a license from a central government authority, such as the Central Insecticides Board and Registration Committee (CIBRC) in India. You also need to comply with all local and national environmental protection and safety regulations. This includes proper waste disposal, emissions control, and a comprehensive safety plan for your employees.

What kind of research and development is needed for pesticides?

Research and development (R&D) is crucial for a pesticide business. It involves a team of chemists and scientists who work on creating effective pesticide formulations. This includes testing different combinations of active and inert ingredients to ensure the product is potent against pests while minimizing harm to the environment and non-target organisms. R&D also helps you comply with regulations and develop new, more effective products.

Is a large investment required for a pesticide manufacturing unit?

Yes, a significant investment is typically required to start a pesticide manufacturing unit. This is due to the need for specialized machinery for mixing and packaging chemicals, which can be expensive. You also need to invest in a facility that meets strict safety and environmental standards, which can be a major cost. Additionally, the investment in research, licensing fees, and compliance can be substantial.

What are the main safety measures in a pesticide manufacturing plant?

Safety is a top priority in a pesticide plant. Key safety measures include proper ventilation to prevent the buildup of chemical fumes, mandatory use of personal protective equipment (PPE) for all employees, and strict protocols for handling and storing hazardous materials. The facility must also have emergency response plans in place to handle spills or accidents, including a well-equipped first-aid station and trained personnel.

How do I ensure the quality of the pesticides I manufacture?

Ensuring the quality of pesticides requires a rigorous quality control process. Every batch of products must be tested for the correct concentration of the active ingredient and for purity to ensure it is free from contaminants. The product’s stability and shelf life must also be tested. This ensures that the pesticide remains effective over time and that it meets all regulatory standards before it is sold to the public.