India will be at a turning point in its history by August 2025. The nation’s position as a global manufacturing leader is being solidified by government initiatives such as ‘Make in India,’ and Production Linked Incentive schemes (PLI). This presents a unique opportunity for aspiring entrepreneurs. In India, starting a manufacturing company is more than just building a factory. It’s also about creating value and contributing to the national vision of self-reliance Aatmanirbhar Bharat.

The prospect of a factory is exciting. However, the road from an idea to a busy production floor is complex. It requires meticulous planning, financial expertise, and a thorough understanding of the regulatory environment. This comprehensive guide will act as a step-by-step roadmap, guiding you through the complexities, and giving you the tools to turn your entrepreneurial dream into an actual, successful manufacturing business.

Phase I: The Foundation – Ideation and Meticulous Plan

The foundation of any venture is laid on paper.

1. You can identify your product and niche by identifying the following:

It is important to choose what you want to produce. Passion is great, but must be supported by the market.

- Market research: Do thorough market research to identify product gaps. What sectors receive government support? Electronic assembly, electric vehicle components, food processing and specialty chemicals are among the sectors that will grow most rapidly in 2025.

- Feasibility study: Once an idea is conceived, it’s important to assess its feasibility.

- Technical Feasibility Can you access the necessary technology and skilled workers?

- Market Feasibility: Which are your target clients (B2B, B2C or both)? What is the size of your market? What are your competitors doing?

- Financial feasibility: What are the projected project costs and potential profit margins for the project?

Read More: Most Profitable Small Scale Manufacturing business Ideas for Indian Startups

2. How to Write a Bankable Business plan

The single most important document that you will ever create is your business plan. This document is not only for securing a loan, but also your roadmap for the next three to five year. It must be realistic, detailed and data-driven.

- Executive summary: An overview of the entire plan in a concise manner.

- Company description: Your vision, mission, legal structure and what makes you unique.

- Product/Service line: A detailed description of the products and services you plan to manufacture, including raw material specifications and production methods.

- Market analysis: In depth analysis of your industry and target market.

- Operation Plan: Details about your factory location, equipment, supply chain and quality control processes.

- Management team: Profiles for the key people who drive the business.

- Financial Projection: Included in this section are projected startup costs, income and expense statements, cash flow statement, and break-even analyses for at least three year.

Read More: How to Start Artificial Marble Tiles Manufacturing Industry

Phase 2 – The Legal and Financial Framework

After you have a plan, the next step is to build the legal and financial framework of your business.

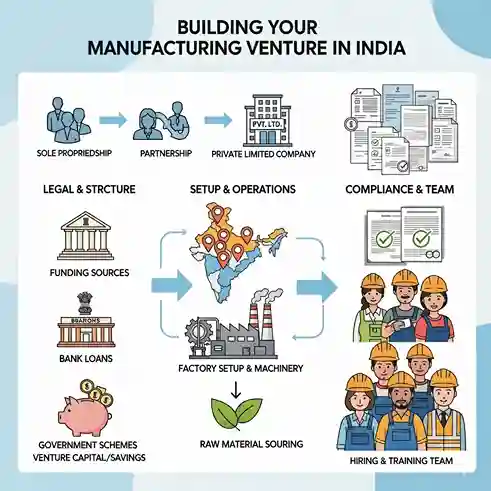

1. The Right Business Structure

Your company’s legal structure impacts everything, from taxation to liability. In India, the most common structures are:

- Single Proprietorship Easy to set up but no liability protection.

- Partnership firm: Two partners or more share profits and liabilities.

- Limited Liability Partnerships (LLP): This hybrid model offers the flexibility of a partnership with the added benefit of limited liability.

- Private Limited Company (Pvt. Ltd .): This is the preferred structure for manufacturing businesses that are scalable. It has limited liability and makes it easier to raise money.

Read Our Book: Click Here

2. Organizing Your Finances

Capital is required for manufacturing. How much capital you require will be determined by your business plan. The following are key sources:

- Personal funds (Bootstrapping). The most common way to start is with your own savings.

- Bank loans: Contact commercial banks and present your business plan. MUDRA Yojana, which offers smaller loans, and Credit Guarantee Fund Trust for Micro and Small Enterprises(CGTMSE), a scheme that provides loans without collateral are two of the most important schemes.

- Government schemes: Prime Minister’s Employment Generation Programme offers subsidies for new businesses.

- Venture Capital & Angel Investments: You can pitch investors to get equity funding if your product has a high growth potential and is innovative.

3. Registering for Essential Services

You will need: You will need the following:

- Director identification number (DIN). For all directors.

- Digital Signature Certificate (DSC) for online filings.

- Approval of Company Name, and registration at the Ministry of Corporate Affairs.

- Tax Deduction account Number (TAN) and Permanent Account number (PAN) for your company.

Phase 3 – The Build Out – Setup & Operations

Here, your vision begins to take physical form.

1. Selecting a Location

The right location is an important strategic decision. Consider:

- Close proximity to raw materials: Reduces transport costs and logistical delay.

- Access Markets: Can you easily ship your finished products to your customers?

- Availability: Access both to skilled and unskilled labor.

- Infrastructure Power supply, water and road connectivity.

- Zoning Regulations: Search for Special Economic Zones or designated industrial zones, which provide tax incentives and simplified clearances. Exploring industrial parks in West Bengal can be very beneficial for an entrepreneur.

Read Our Project Report: Click Here

2. The maze of licenses and permits

It can be the most difficult step. Checklists are essential for a typical manufacturing unit.

- Udyam registration: A fundamental registration for all MSMEs, with many benefits.

- Factory license: Obtained by the Chief inspector of factories in your state.

- Pollution Control Permits: You need a “Consent to Establish” (CTE) from the State Pollution Control Board before you can start your production and a “Consent To Operate” (CTO) to begin.

- GST registration: Mandatory if you sell interstate or if your sales exceed the threshold.

- Fire Department Noc: To ensure that your facility meets the fire safety standards.

- Trade license: The local municipal authority.

- Licenses for specific sectors: An example would be a FSSAI licence for food processing, or BIS certification of certain electronic goods.

Read More: Made in India: Your Guide to the Most Profitable Manufacturing Business in India

3. Procuring machinery and sourcing raw materials

- Machines: Determine whether you should buy new or second-hand machinery depending on your budget and technology requirements. Compare multiple quotes, and take into account factors such as after-sales services and spare parts availability.

- Raw Material: Determine at least two or three suppliers of each raw material that is important to ensure pricing and quality.

4. Hire and Train Your Team

Your employees are your most valuable asset. Employ a combination of supervisors with experience and workers who are willing to learn. Prioritize safety training, and establish a clear organization structure.

Discover the Right Business for You With Our Startup Selector Tool

Conclusion

In 2025, starting a manufacturing company in India will be a huge challenge. But the rewards are even greater. This path is filled with financial obstacles, complex regulations and operational difficulties. The supportive government policies, the vast domestic market and a growing focus on local production provide fertile ground for growth. Your compass is a carefully crafted business plan that will guide you through every phase of your enterprise with clarity and purpose.

How To Start Manufacturing Business in India: FAQs

Q1. How much money do you need to start a small factory in India?

It really depends on what you want to make. If you want to make food or clothes, you might need ₹10-25 lakhs. But if you plan to make electronic parts or something fancy, you may need ₹50 lakhs or even over ₹1 crore.

Q2. What government schemes can help in 2025?

There are some helpful schemes out there. PLI (Production Linked Incentive) helps if you work in certain fields. MUDRA Yojana gives loans up to ₹10 lakhs without asking for your house or land as security. If you need a bigger loan, CGTMSE can help, again without needing your property as a guarantee. The PMEGP scheme can give you some money back on your project costs.

Q3. What is the hardest part about starting a factory in India?

Money is always tough. But the hardest part is dealing with all the rules and paperwork. You need many permissions from different government offices. Each office has its own rules and checks. You must keep everything up to date, or you can get into trouble. It takes a lot of time and attention.

Q4. Should you build your factory in a village or a city?

Villages are cheaper. Land and workers cost less. But roads, electricity, and skilled workers can be hard to find. Cities and nearby industrial areas are more expensive, but you get better roads, good workers, and you are closer to buyers. If you can find space in an industrial park, that is usually a good choice.

Q5. How long does it take from idea to making your first product?

It takes time. Most people need 10 to 18 months. You spend a few months planning and finding money. Then more months to register your company and get all the right papers. Setting up the building and machines takes a few more months. After that, you hire and train people and test everything. So, it is a long process, but you get there if you keep going.