Beer is the oldest and most popular beverage in the world. Beer manufacturing has become a huge business in recent years. From small craft breweries, to large industrial beer plants. If you know the market, how to make money, and what legal requirements are, a beer factory can be a highly profitable business.

This guide will cover every aspect of beer production, from the raw materials to the packaging, so even a novice can understand.

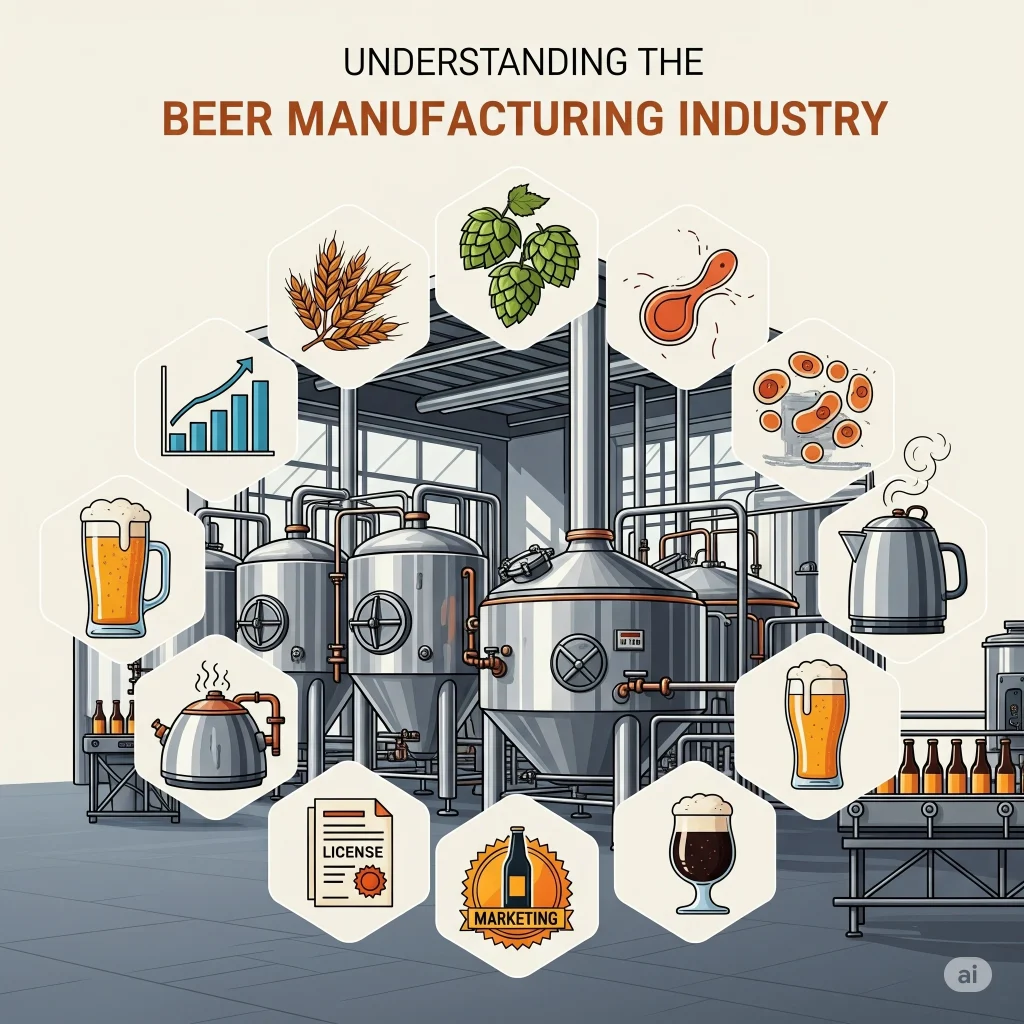

Understanding The Beer Manufacturing Industry

Beer production is an ancient industry with roots that date back to thousands of years. It has evolved into a highly profitable and modern business sector. You can categorize beer into large commercial breweries (such as Budweiser and Heineken), craft breweries (such as microbreweries), and microbreweries. Each category has its own target audience, pricing strategies, and production capacities. To understand the market, you need to analyze the current trends in beer consumption, determine which flavors and styles sell, and know your competition. Branding, marketing and distribution are all part of a beer manufacturing business.

Market Potential and Demand

Due to the changing lifestyles, social events and urbanization, beer is in high demand around the globe. In many areas, the market shifts to premium and craft beers, giving entrepreneurs more creative freedom and greater profits. Global beer consumption, according to industry reports is measured in billions of liters per year. The market potential in countries with large populations of youth is even greater. Entrepreneurs must first assess the local regulations and culture acceptance before starting because demographics, legal restrictions and other factors can affect beer demand.

What Types of Beer Can You Manufacture

Manufacturer can produce Beer in many different types, including:

- Lager: Brew Light, crisp beer at low temperature.

- Ale: Brewed with higher temperatures and stronger flavors.

- Porter and Stout: Full-bodied, dark beers with rich aromas.

- Specialty and Craft Beers: Seasonal or flavored beers with unique flavors.

Each type has different brewing techniques, yeast strains and fermentation times. Knowing who your audience is will help you decide what types to produce. Customers have different tastes.

Read More: Banana Wine Making Profitable Business Idea

Set Up The Beer Factory

The first step in setting up a brewery is to choose a location that has easy access to transportation, water, and electricity. Manufacturer must set up separate areas for fermentation, brewing, packaging and storage. To ensure the quality of your product, you need to have a proper ventilation system, control temperature, and maintain hygienic conditions. Entrepreneurs must also obtain the necessary licenses such as brewery permits and food safety certificates. A detailed business plan is essential when setting up the facility, as it can involve a significant investment.

Equipment Required For Beer Manufacturing

The main equipment includes

- Brewhouse System for mashing, lautering and boiling.

- Fermentation tanks: To ferment the beer under controlled circumstances.

- Filtration Units : To remove unwanted particle.

- Bottling and Canning Lines : for packaging.

- Refrigeration Systems: To maintain proper storage temperatures.

Quality equipment is essential to ensuring consistency in taste and efficiency of production.

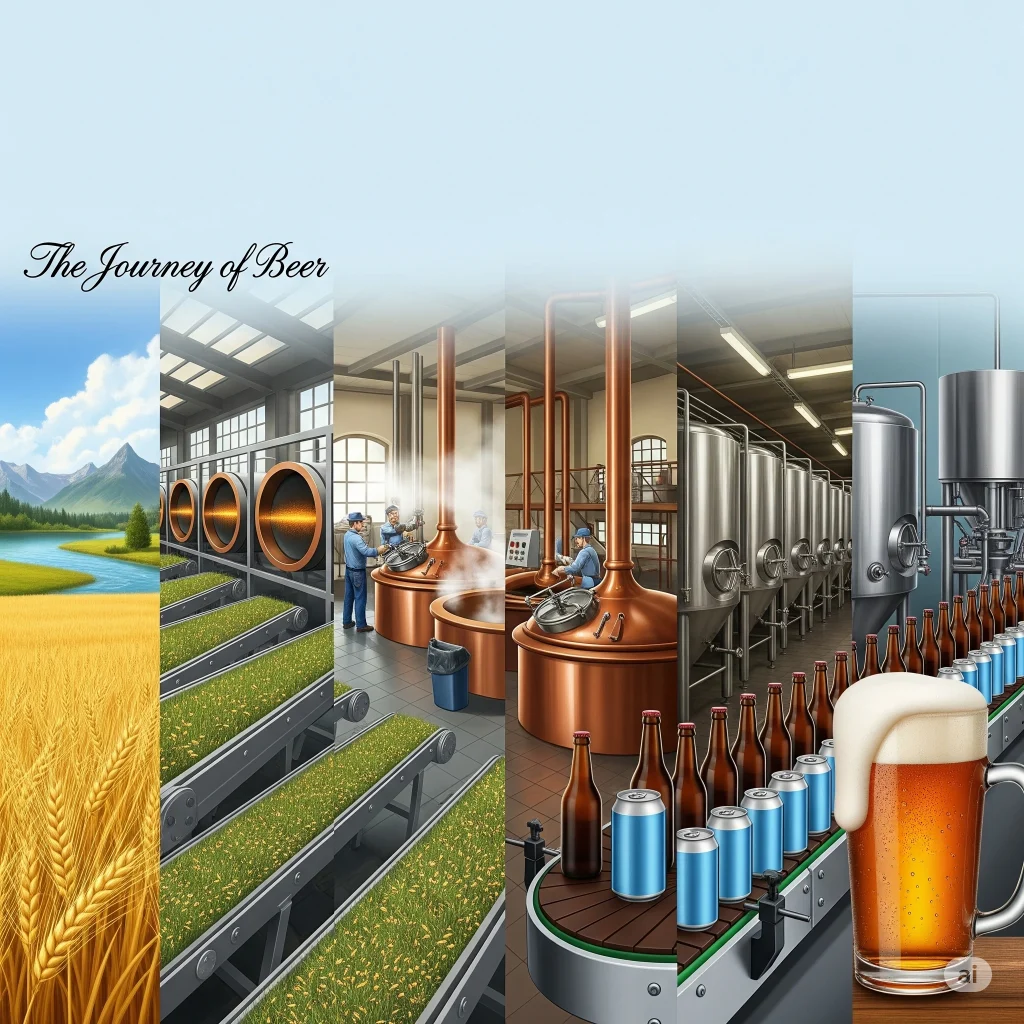

The Beer Manufacturing Process Detailed

This process usually includes the following steps:

- First, you soak barley, let it sprout, and dry it out. That’s how you turn plain old grain into malt.

- Then, mix that malt with hot water. You’re basically stealing all the sugars, setting up for the fun stuff later.

- After that, boil everything and toss in hops. The hops bring the attitude—bitterness, aroma, all that jazz.

- Next, you add yeast. The yeast gets to work, gobbling up sugars and cranking out alcohol and bubbles. It’s wild.

- After fermentation, let the beer chill out and mature. That’s when it smooths out and picks up its real flavor.

- Finally, pack it up—in kegs, bottles, cans, whatever. That’s how the beer makes its way to you.

To maintain food safety and consistency, each stage must be subjected to strict quality control.

Read More: Foreign Liquor: A Guide for Everyone

Raw Materials And Their Quality

Malted barley is the main raw material, followed by hops, water, and yeast. Each ingredient has a direct impact on the flavor and aroma of beer. For instance, fresh hops enhance flavor while mineral-balanced water improves mouthfeel. To maintain consistent quality, it is important to source ingredients from reliable sources.

Cost Estimation And Investment

The scale of the brewery will determine how much money you need to invest. Land, construction, machinery and raw materials are all included in the costs. While small-scale craft breweries can start with lower capital, large-scale commercial plants may require millions of dollars. Include in your detailed cost analysis the licensing fees, as well as working capital required for the first few weeks.

Licenses And Legal Compliance

Entrepreneurs must adhere to all licensing requirements. The registration of the business is required, as well as obtaining a brewer’s license, adhering to food safety laws and alcohol distribution laws. Failure to comply could result in severe fines or the closure of your business. Compliance with the law also helps to build trust among distributors and clients.

Marketing And Branding Strategies

Branding is the key to a successful beer business. Customers can be attracted by a unique logo, creative package, and memorable story. Some marketing strategies include hosting beer tasting events, launching new seasonal flavors, and partnering up with restaurants and pubs. Social media marketing and influencer partnerships can increase brand awareness.

Read Our Book For Your Business: Click Here

Distribution Channels

Beer can be sold through a variety of channels. Using more than one will increase profits and brand awareness.

- Directly to Restaurants and Bars– Breweries supply hospitality businesses such as bars, pubs and restaurants. This helps to build strong relationships with managers and owners. Customers will be familiarized with the brand if the beer is available at popular places. They may even start to request it elsewhere if the beer becomes widely available. Direct supply also gives you better control of pricing and quality.

- Supermarkets and Retail Shops– Beer is available in supermarkets and retail shops to customers who like to buy beer in bulk. This channel increases brand awareness because the products are displayed on shelves next to competitors, which attracts casual buyers.

- Online Alcohol Deliveries– In areas or countries where alcohol is legal to buy, consumers can order beer online. It is particularly important for urban areas, where convenience is key. Breweries can reach younger, tech-savvy audiences that prefer doorstep delivery with effective packaging.

- Brewery Sales Many breweries have taprooms, or small bars where guests can enjoy freshly brewed beer. Some breweries also sell canned or bottled beer from their premises. It not only creates revenue, but also a direct relationship between the brewery’s customers. Visitors share their experiences on social media, which gives the brand free advertising.

Before starting your business, it is essential to have a detailed business plan and feasibility study. This will include market research, production capacity, cost analysis, and profit projections.

Why Multiple Distribution Channels Matter– By using multiple distribution channels, beer can be made available to a variety of customers – from those who are relaxing at a pub or shopping in a supermarket to online purchasers. Multiple channels increase sales and brand recognition. They also reduce risk when one channel’s sales fall.

Beer Manufacturing Business: Opportunities and Challenges

It is possible to run a profitable beer manufacturing business, but there are certain obstacles:

- Raw Material Prices Changing Beer is made from ingredients such as barley, yeast, hops and water. The price of barley and hops may increase due to poor weather, lower harvests or an increased demand. These price fluctuations can affect profit margins. Breweries that are successful often have multiple suppliers and contract farmers in order to maintain a stable supply of beer at a reasonable price.

- The Competition of Established Brands– Big beer brands are well established and have a long history in marketing, strong customer loyalty and a massive distribution network. To compete, new businesses need to stand out by offering unique flavors, creative branding or local appeal.

- Consumer preferences – Beer tastes can change rapidly. Craft beers, for example, may be popular one year and light beers or beers with flavors the next. Breweries need to keep up with market trends, and develop new products that meet customer demand.

- Legal Restrictions– Alcohol production is heavily regulated. These rules may include licensing, taxation and advertising restrictions, packaging requirements and age restrictions. To avoid penalties or closures, it is important to understand and follow local laws.

- Maintaining quality during expansion– It can be difficult to maintain the same taste and quality when production increases. A drop in quality could lead to a loss of customers. Maintaining consistency can be achieved by investing in new equipment and implementing strict quality controls.

Opportunities– The beer market, in particular the premium and craft brands, is growing despite the challenges. Breweries with unique recipes, local sourcing and sustainable practices will build loyal fans and grow.

You can access a ready-made Project Report to understand the complete requirements and financial planning for setting up a beer manufacturing unit.

Sustainable Beer Manufacturing Practices

Breweries today are focused on environmentally friendly production in order to protect the planet and attract customers who care about the environment.

- Reusing Water– Making beer uses a lot water. Breweries recycle their process water for use in cleaning equipment, landscaping or even brewing. This helps reduce waste and costs.

- Renewable Energy– Solar panels or wind turbines can be used to power brewing plants. Breweries can reduce greenhouse gas emissions by using renewable energy.

- Reducing waste packaging– Many companies have switched to biodegradable packages, reusable bottles or aluminum cans which can be easily recycled. Even labels and adhesives have been redesigned for a more eco-friendly look.

- Source Local Ingredients– Buying local ingredients such as barley, hops and other materials reduces transport emissions and supports local economies.

- Byproducts and Compost– Spent grains (leftover after brewing), can be used as animal feed by farmers or baked into goods. This practice transforms waste into useful products.

Why Sustainability is Important – Adopting sustainable practices helps not only the planet, but also enhances your brand’s image. Customers actively select products from companies who are environmentally conscious. Sustainability in brewing reduces costs over time by lowering water and energy bills.

Want To Know About Which Business Idea Would Be Better For You?

Go Through Our Startup Selector Tool

Conclusion

If you combine your brewing knowledge with smart marketing, and strict quality control, the beer manufacturing business could be lucrative. Success depends on following legal guidelines, offering unique flavors and building a strong branding, whether you are starting a small brewery or a large factory.

FAQs

Q1 : How long is the process of making beer in a brewery?

The process takes between 2 and 4 weeks depending on the type of beer.

Q2: Is beer brewing profitable?

Yes, if managed well. Craft beer is profitable, and big factories can benefit from their scale.

Q3 Can I start my own beer factory?

Yes, you can do it for your personal use. However, selling is not allowed.

Q4 What is the shelf-life of beer?

A Most beers will last between 6-12 months when stored properly.