Aluminium is a key component of the industrial ecosystem. It is one of the world’s most popular non-ferrous materials. Aluminium is used in almost all industrial and consumer sectors, from automobiles to aircraft, power transmission lines to packaging foils. The manufacturing business of aluminium ingot from aluminium scrap. Aluminium’s unique property that it is infinitely recyclable while maintaining its quality makes it an important cornerstone in modern economies moving towards circularity and sustainability.

The business is not only more cost-effective, but it also has a positive impact on the environment. The manufacturing business of aluminium ingot from aluminium scrap is a great way for entrepreneurs to get into the manufacturing industry. It offers profitability, sustainability, and scalability.

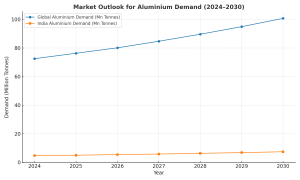

Aluminium Ingots Market Outlook in India and Global

Aluminium ingots are used for a variety of applications, including transportation, packaging and building, consumer durables and electrical products. Aluminium’s value is set to increase as the demand for lightweight, recyclable and energy-efficient materials increases.

Market Demand and Forecast (2019-2030).

| Year | Global Aluminium Demand (Million Tonnes). | India Aluminium Demand (Million Tonnes). | Global Market Growth Rate |

| 2024 | 72.5 | 4.7 | 5.2% |

| 2025 | 76.3 | 5.0 | 5.5% |

| 2026 | 80.1 | 5.4 | 5.6% |

| 2027 | 84.7 | 5.8 | 5.8% |

| 2028 | 89.6 | 6.3 | 5.9% |

| 2029 | 94.9 | 6.8 | 6.0% |

| 2030 | 100.7 | 7.4 | 6.1% |

The Forecast:

- By 2030, the global aluminium market is expected to exceed 100 million tonnes.

- India’s aluminium demand is growing faster than the global average due to urbanization, infrastructure investment, and the renewable energy sectors.

- The recycling of scrap aluminium and ingots made from it will be a key factor, since they use 95% less energy compared to primary aluminium production.

Related: The Aluminium Industry in India: A Growing Export Powerhouse

Why entrepreneurs should enter aluminium scrap recycling

- Demand for Sustainability and High Demand

Recycled aluminium is becoming the material of choice as industries strive to reduce their carbon footprints. Secondary aluminium is being adopted at an unprecedented rate by the automotive and packaging industries. - Resource Efficiency

Aluminium scrap can be recycled to reduce environmental impact and save natural resources. It also requires less capital compared to primary smelting. - Policy and Regulatory Assistance

In order to promote recycling, many countries, including India offer incentives and stricter regulations on waste management. - Scalability

Entrepreneurs can begin with a small facility and grow it as the demand increases, thus ensuring their long-term viability.

Why Aluminium Scrap Recycling is a Lucrative Business

The advantages of starting an aluminium ingot business from scrap are numerous. Sustainability is the first advantage. It is not only a social obligation, but also a way to differentiate your business. The pressure is on companies in all sectors, but especially automotive and packaging, to reduce their carbon footprint. They can reduce emissions by sourcing recycled aluminium ingots.

Energy efficiency is the second benefit. Aluminium produced from scrap uses a lot less energy than aluminium smelted from bauxite. This results in lower operating costs, increased margins, and improved competitiveness for businesses that recycle. This factor is enough to make scrap-based ingots attractive for a country such as India where energy costs are increasing and environmental regulations are getting stricter.

Government initiatives are also creating favourable policy environments for recycling around the globe. In India, policies that promote recycling and stricter waste management regulations, as well as extended producer responsibility standards, are strengthening the ecosystem.

Related: Start an Aluminium Recycling Business

Aluminium Ingots: Industrial Applications

Aluminium ingots made from recycled scrap are a valuable input material for multiple industries. It is widely used in the automotive industry to manufacture engine blocks, cylinder heads, wheels, body structures, an,d more recently, in electric vehicles, which require lightweight materials.

Construction also uses a large amount of aluminium ingots for the manufacture of roofing materials, panels and structures. The demand for construction-grade aluminium has been steadily rising due to rapid urbanisation and smart city initiatives.

Aluminium is used in packaging because it provides a strong, lightweight barrier to moisture, oxygen, and light. Aluminium ingots recycled are made into foils and sheets that are used for beverage cans, food containers, and pharmaceutical packaging.

It is used in electrical applications such as conductors and power cables. Its excellent conductivity makes it a cost-effective material. Aluminium is also used in consumer durables like refrigerators, air conditioners and kitchen appliances. The diverse range of applications means that the demand for aluminium ingots is resilient to economic cycles.

For more information check out our Handbooks on Steel, Iron, Ferrous, Non-Ferrous Metals with Casting and Forging, Aluminium, Ferroalloys Technology

Production of Aluminium Ingots From Scrap

Transforming scrap aluminium into ingots of high quality requires a series of carefully-controlled processes. The first step involves collecting and sorting scrap metal from different sources. Scrap includes industrial waste, old vehicles, household goods, and beverage containers. Sorting is crucial, since impurities and other materials such as non-aluminium can affect the quality of final ingots. To ensure greater purity, advanced mechanical and sensor-based sorts are being used more often.

After sorting, the scrap undergoes shredding and a pre-treatment. To facilitate handling and ensure uniform melting, large pieces are broken into smaller fragments. To remove paints, lacquers, and other contaminants, pre-treatments such as decoating, delacquering, or surface cleaning may be carried out.

Aluminium melts at 660. The scrap is fed into furnaces, which are commonly rotary or reverberatory. Refining agents such as hydrogen and oxides are added during melting to ensure the aluminium reaches the required purity.

The Industry’s Growth Drivers

The growth of aluminium scrap recycling is driven by several structural trends. Globally, the circular economy movement is most important as corporations and governments strive to reduce waste and maximise resource reuse. The aluminium industry is a perfect fit, as the metal can be recycled without losing its quality indefinitely.

Another key driver is the rise of electric cars. Aluminium is a lightweight material that EV manufacturers use to increase battery efficiency and range. This sector is expected to increase its demand for recycled aluminium ingots because they are cost-effective and environmentally friendly.

The construction boom in Asia, especially India and China, is driving demand for durable and affordable aluminium products. The rapid growth in the packaging industry, driven by urbanisation and e-commerce as well as consumer lifestyle changes, is also increasing the consumption of aluminium sheets, foils and cans.

Challenges Entrepreneurs Should Consider

Aluminium scrap recycling is no different. The primary concern is maintaining consistent scrap quality. Contamination of ingots by non-metallic or other metals can impact the quality and lead to customer rejection. Entrepreneurs should invest in robust mechanisms for sourcing and sorting.

Another important factor is technology. To produce ingots that are up to industrial standards, efficient furnaces, refinery systems, and quality-control mechanisms are necessary. Businesses that do not have the correct technological setup risk increased production costs and reduced product acceptance.

There is a high level of competition in the industry, and established players are operating at scale. The global aluminium market can have a significant impact on profitability. Imports may also increase pressure. To navigate these challenges successfully, it is important to maintain efficiency, quality and strong customer relations.

Entrepreneurship Opportunities in India

India’s rapid industrial development provides fertile ground to aluminium scrap recycling companies. The government’s emphasis on renewable energy and electric mobility, as well as infrastructure development, ensures a sustained demand for aluminium products. In states like Maharashtra and Gujarat, as well as Odisha and Chhattisgarh, entrepreneurs can benefit from significant logistical benefits by establishing ingot manufacturing facilities near industrial clusters.

The export potential for recycled aluminium ingots is also strong. Demand comes from places like Europe and the Middle East, where environmental regulations are strict. Indian entrepreneurs can take advantage of low production costs in order to create export-oriented businesses. Urban mining is another opportunity to ensure long-term availability of raw materials.

Environmental Benefits of Recycling

Recycling aluminium is more than a way to make money; it’s a necessity for the environment. It reduces greenhouse gas emissions by 95 per cent when compared with primary production. Recycling aluminium can save several tonnes of carbon dioxide emissions.

Recycling conserves natural resources and reduces the impact on the environment. It also addresses the problem of waste management, preventing aluminium from being dumped in landfills. This alignment with sustainability goals increases brand value for entrepreneurs and opens new market opportunities.

View the related video on this article

Role of NPCS for Aluminium Ingot Projects

Niir Project Consultancy Services provides vital support to entrepreneurs looking to enter the sector. NPCS provides detailed techno-economic feasibility reports and market surveys to help startups make informed choices. The reports include all aspects of project planning, including manufacturing processes and raw materials, as well as plant layouts and financials. NPCS helps entrepreneurs to assess the feasibility of establishing new businesses or industries, ensuring they have a solid foundation for their business.

Find Profitable Business Ideas Tailored to You With Our Tool

The Conclusion of the article is:

Manufacturing aluminium ingots out of scrap aluminium is one of the most exciting industrial opportunities for this decade. Profitability and sustainability are combined by leveraging an abundant, reusable resource that is indispensable to modern industries.

India’s rapidly growing aluminium market, its favorable policies and the abundance of scrap create an advantage for startups. Entrepreneurs can gain a competitive edge in this industry by focusing on reliable supply chains and quality control.

Expert guidance from companies like NPCS is available to those who are ready to leap. Aluminium scrap recycling is more than just a good business idea. It is also a crucial contribution to sustainable industrial growth.