In the food and nutrition sector, there has been one crucial change recently: how ingredient suppliers strategize. End users like bakery chains, ready-to-eat food manufacturers, and pharmaceutical and supplement companies now favor ingredients with a shelf life and storage of protein-rich content at room temperature, like egg powder.

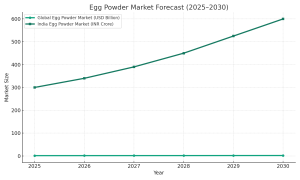

Analysts valued the global egg powder market at approximately USD 1.2 billion in 2023 and project it to reach around USD 1.75 billion by 2029. This is an increase of 1.3 billion or a 6.5% compound annual growth rate. A rising appetite for convenience foods and urbanization, greater awareness of protein-rich diets, and the need for supply chain optimization are the driving factors for growth.

India’s Emerging Role

India is already one of the top egg-producing countries in the world, and is in a good position to increase its share in the global egg powder market. Looking at the domestic egg production, it has already crossed 130 billion eggs annually, but the extent of the eggs processed into powder is still quite low. This gap is a great opportunity.

Government programs, infrastructure projects like Mega Food Parks, and increasing export opportunities from Southeast Asia, Africa, and the Middle East are motivating businesspeople to venture into egg processing. Indian exporters surpassed ₹250 crore in egg powder exports during the fiscal year 2024. With strong support from the Make in India program and Agri Export Zones, the sector now stands poised for explosive growth.

In our previous articles, we spoke about the expected growth from the booming population. Now, we bring something for the manufacturing sector. Over the next five years, we expect the demand for egg powder to grow for both international and Indian markets. The pandemic has increased access to food delivery services and raised food security awareness, which continues to accelerate this growth.

| Year | Global Market Size (USD Billion) | India Market Size (INR Crore) |

| 2025 | 1.34 | 300 |

| 2026 | 1.43 | 340 |

| 2027 | 1.51 | 390 |

| 2028 | 1.60 | 450 |

| 2029 | 1.75 | 525 |

| 2030 | 1.88 | 600 |

This is a huge opportunity for Indian entrepreneurs. Not only is the country a major producer of eggs, but the low cost of labor, increasing infrastructure, and proximity to countries with high demand are a competitive advantage. This is great news for start-ups and SMEs looking to grow.

Related: Production of Egg Powder: Feasibility and Techno-Economic Viability Study

Manufacturing Process: Production Workflow of Egg Powder

This process of producing egg powder starts with egg collection, which is then followed by pasteurization. Drying is then conducted to obtain powder of egg which is then packed. The whole process carries some steps, which would be described in detail below.

Egg Reception and Cleaning

The process starts with fresh farm-sourced eggs. This is the most crucial stage of production since it requires a careful selection of fresh eggs. For egg washing, the outer dirt and microbes that are found on the egg is scrubbed with soft brushes and sanitized. This ensures that the egg does not get damaged while the dirt is being removed.

Breaking and Separation

The process of cracking egg is quite easy. The devices that are utilized for this process are quite advanced in the sense that they break the egg with yolk and egg white separating for each half. Depending upon the demand in the market, some firms blend both while some focus on either yolk or white.

Filtration and Homogenization

Chalazae or any other stringy parts and impurities are removed from the egg mass liquid through filtering. To maintain the liquid’s consistency before pasteurization, homogenization is performed. The aim is to obtain a uniform, smooth blend that can dry completely and retain a stable structure.

Pasteurization

Particularly, if the egg powder is to be exported, this is a critical step. The liquid is filtered and then heated to a temperature of 60 to 65 degrees Celsius, and held for a set time to remove Salmonella and other harmful microorganisms. Proteins must not be coagulated, and thus, proper time management is necessary to ensure safety during the process.

Spray Drying

This is the most important step in the processing of egg powder. In this step, the liquid that has already been pasteurized is placed into a spray dryer, where it is converted into the desired fine particles through the use of a hot air chamber. This vaporizes any excess moisture and transforms the liquid into a dry powder in seconds. The final product’s texture and solubility is determined by the critical parameters of control like feed rate, air flow, and how hot the chamber is.

Cooling and Sieving

To maintain the quality of the powder, it has to be cooled immediately after drying and is then sieved to remove oversized particles and agglomerates. Consistency of the fine powder improves the rehydration rate and enhances application in industrial formulations.

Packaging and Storage

The final product is packed under strict hygienic conditions into vacuum-sealed or nitrogen-flushed containers to avert oxidation. Storage conditions need to be cool and free of moisture. With proper packaging, the egg powder has a shelf life of 12 to 24 months, making it easy for international shipping and B2B sales.

Related: Low-Investment Eggshell Powder Business Ideas for MSMEs and Rural Entrepreneurs

Key Product Variants and Their Applications

Egg powder manufacturing can be tailored to the specific needs of a business, meaning different variants can be supplied to different industries.

Whole egg powder is used in baking, and it is a major component in the production of pasta and ready-to-eat meals. It provides the functionality of fresh eggs making it a good ingredient for food processors.

Egg Albumen Powder (white only) has extensive application in the confectionery and aerated products markets, as well as in nutrition supplements owing to its high protein content. Food producers use egg yolk powder in meringues, soufflés, and protein shakes for its excellent foaming and binding abilities.

Manufacturers use egg yolk powder in high-fat products such as sauces, mayonnaise, and ice cream. Cosmetic companies also use it as an emulsifier in various skincare formulations. Depending on their machinery and target audience, manufacturers tend to produce one or more of these.

Competitive Edge and Potential for Exports

Exports present the most promising opportunity for profit in the manufacturing of egg powder. Indian manufacturers are increasingly tapping international markets for egg products that are high in protein and have a long shelf life. Japan, Germany, UAE, Singapore, and South Korea are significant importers. Domestic firms benefit from price advantages, and the growing reputation of India’s food processing sector has enhanced credibility overseas.

Maintaining compliance with strict food safety standards greatly influences export success. Obtaining ISO, Halal, or Kosher (depending on the targeted market) and APEDA or EIC registered labeling are crucial.

Indian entrepreneurs must tailor documentation and packaging to meet the specific needs of their target country. To achieve successful exports, they should implement strong digital B2B marketing strategies, build reliable logistics partnerships, and streamline their supply chains.

Strategic Business Planning and Considerations for Entrepreneurs

Besides investing in equipment and machinery, an entrepreneur venturing into egg powder production must establish an effective supply chain that focuses on these essential elements:

- Traceable and consistent poultry suppliers for a steady and reliable egg supply.

- Cold Chain retail facilities for storing stock.

- Automation and hygiene controls for food processing.

- Marketing and regulatory compliance in the target market.

- Domestic and international marketing and sales strategy for institutional clients and B2B sales.

To broaden their marketing and sales reach, manufacturers can also produce customizable egg powder variants, such as flavored or fortified for specialized verticals like infant and senior nutrition, as well as for veterinary products.

Manufacturers must also target the domestic market by establishing B2B sales relationships with food service providers like bakeries, food processors, airlines, and restaurants, as well as participate in international trade shows and join online food ingredient marketplaces to establish international connections.

About NPCS – Supporting Entrepreneurs with Clarity

If you’re an aspiring entrepreneur or manufacturer looking to step into the egg powder industry, technical clarity and market insight are essential.

Niir Project Consultancy Services (NPCS) offers specialized support to help you get started confidently:

- NPCS prepares Market Survey cum Detailed Techno Economic Feasibility Reports for new industries.

- These reports cover every critical detail from manufacturing processes, raw materials, machinery, and plant layout to financials and regulatory considerations.

- With decades of experience, NPCS helps startups assess the feasibility, scalability, and risks associated with setting up new manufacturing businesses.

Their services are particularly useful when seeking investor backing or government incentives.

For more information, check this video on Egg Powder

The Road Ahead: Protein, Portability, and Precision

As the global population becomes more urban and nutritionally aware, demand for safe, portable, and protein-dense food options will increase. Egg powder fits squarely into this paradigm. Its use will expand beyond traditional foods into:

- Functional snacks and protein bars

- Emergency rations for disaster zones

- Military and space food systems

- Hybrid protein-based vegan-egg blends

- Medical and geriatric nutrition

With ongoing innovation in spray drying, pasteurization, and clean-label packaging, egg powder will become a core ingredient in the future of food. Entrepreneurs entering this field today stand to benefit from a wave of transformation in both global food security and ingredient traceability.

Find Best Idea for Yourself With our Startup Selector Tool

Final Thoughts

Egg powder manufacturing is no longer a niche business. It is an evolving, high-demand sector with strong foundations in India’s agricultural strength and export potential. With the right technology, quality control, and strategic partnerships, new players can build a resilient and rewarding industrial enterprise.

For those who act decisively, the egg powder opportunity is not just about processing a raw product; it’s about adding value to the food chain, innovating in nutrition, and building an export-ready business from the ground up.