Disposable cold drink glasses have become an essential part of modern lifestyles. Whether at restaurants, street food stalls, parties, movie theaters, or large-scale events, these glasses are widely used due to their convenience, hygiene, and affordability. The rising culture of takeaway beverages, fast food consumption, and outdoor catering has made disposable glasses a necessity in both urban and semi-urban markets.

For entrepreneurs and startups, entering this industry presents a highly lucrative opportunity. The demand is fueled by growing food service sectors, lifestyle changes, and increasing awareness of hygiene. At the same time, governments and consumers are encouraging eco-friendly materials, opening new pathways for sustainable product innovation.

Understanding Disposable Cold Drink Glasses

Disposable cold drink glass manufacturers use materials such as plastic, paper, or bioplastics to produce single-use containers. These glasses hold chilled beverages like soft drinks, juices, smoothies, iced coffee, and mocktails. Manufacturers produce them in various sizes, ranging from 100 ml to 500 ml, and distribute them in bulk to retail, food service, and catering businesses.

The product is not just about functionality; it also plays a role in branding and consumer experience. Many businesses customize these glasses with logos, designs, and messages, turning them into mobile advertisements while enhancing brand recall.

Types of Disposable Glasses

Plastic Glasses

Traditionally, plastic glasses made from polypropylene (PP), polyethylene terephthalate (PET), or polystyrene (PS) have dominated the market. They are durable, transparent, and suitable for both carbonated and non-carbonated drinks. However, growing concerns over plastic waste are leading to restrictions in many regions.

Paper Glasses

Paper-based glasses, often with a thin food-grade lamination to prevent leakage, are gaining popularity as eco-friendly alternatives. They are lightweight, biodegradable, and increasingly adopted by businesses looking to reduce their plastic footprint.

Biodegradable and Compostable Glasses

A new segment of disposable glasses is emerging with the use of plant-based bioplastics such as polylactic acid (PLA). These glasses are compostable under industrial conditions and appeal to environmentally conscious consumers and businesses.

Market Outlook and Growth Potential

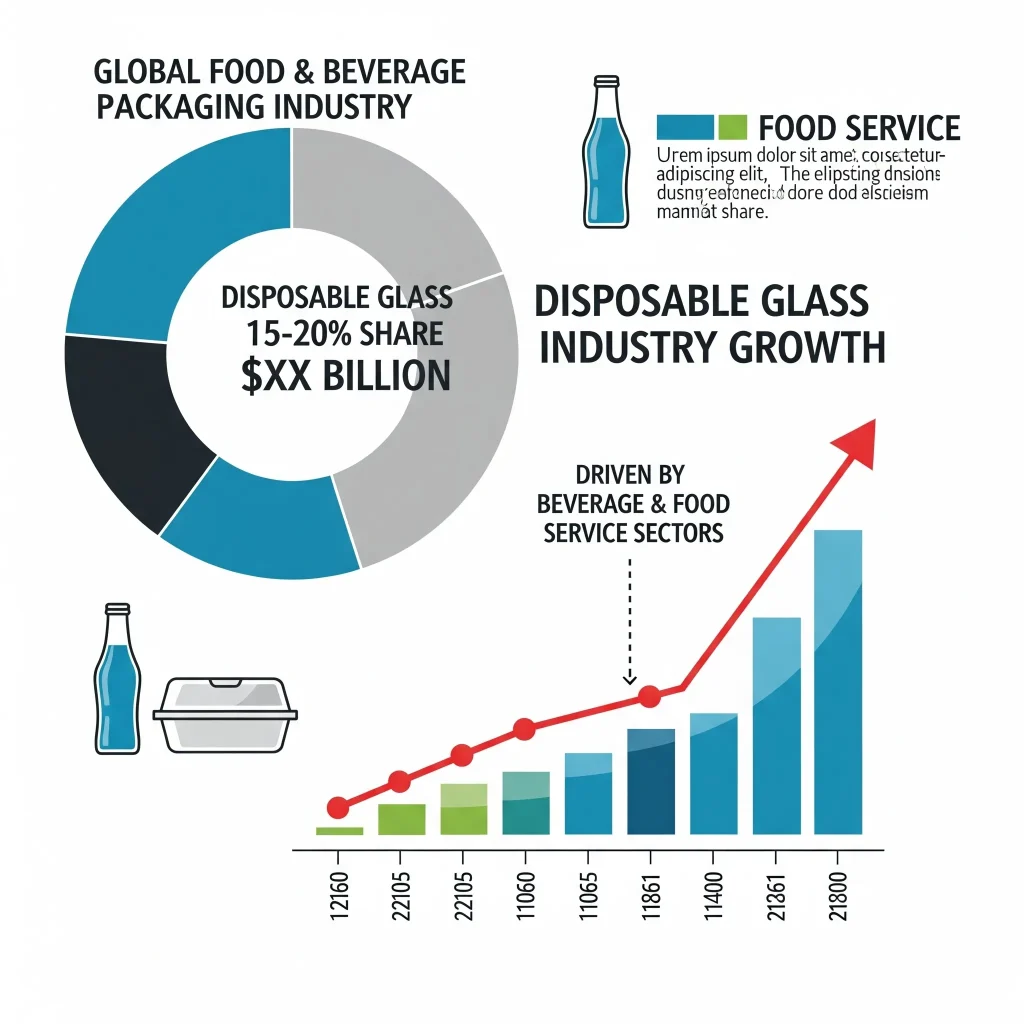

The disposable glass industry is experiencing steady growth, driven by demand from the beverage and food service sectors. With the global food and beverage packaging industry valued in billions of dollars, disposable glasses account for a significant share.

Global and Regional Trends

Analysts project that the global demand for disposable drinkware will grow at a compound annual growth rate (CAGR) of around 5%–7% over the next decade. Emerging economies like India, China, and Brazil are key growth markets due to rising disposable incomes and increasing consumption of ready-to-drink beverages.

Sustainability as a Growth Driver

Eco-friendly products are reshaping consumer behavior. Businesses that invest in recyclable or biodegradable glasses are likely to capture a higher market share. Governments across Asia, Europe, and North America are actively promoting bans on single-use plastics, which further accelerates the shift toward sustainable materials.

Key Demand Drivers

The demand for disposable cold drink glasses is supported by several factors:

- Expansion of quick-service restaurants and café chains.

- Growth in organized retail and online food delivery platforms.

- Rising consumer spending on beverages and convenience products.

- Frequent use at events, functions, and gatherings.

Growth of the Food Service Industry

According to industry studies, the global food service industry continues to expand rapidly. Disposable glasses play a vital role in ensuring hygiene and ease of service, particularly in high-volume establishments. The trend of urban dining and the rise of beverage-focused outlets directly contribute to the increasing demand.

Hygiene and Convenience

Disposable glasses eliminate the need for washing and sanitizing, making them the preferred choice in public and outdoor settings. Post-pandemic, heightened awareness of hygiene has significantly boosted demand.

Branding Opportunities

With advancements in printing technology, disposable glasses can be easily customized. Businesses are leveraging this feature to market their brands directly into the hands of consumers, creating a powerful promotional tool.

Related article:- 5 Best Manufacturing Business Ideas You Can Start with ₹1 Crore

Manufacturing Process of Disposable Cold Drink Glasses

Plastic Glass Manufacturing

Manufacturers typically use extrusion and thermoforming techniques to make plastic glasses. They melt raw polymer granules and extrude them into sheets. The machines then feed these sheets into thermoforming units that mold them into the desired glass shape. Workers or automated systems trim, stack, and pack the final products for distribution.

Paper Glass Manufacturing

Manufacturers produce paper glasses by coating high-quality paper with a thin layer of food-grade plastic or biopolymer to prevent leakage. They cut printed sheets, shape them into cones, and seal them with a base to form the complete glass. Automated systems handle most of this process, enabling large-scale production with minimal wastage.

Quality Testing and Packaging

Manufacturers subject all disposable glasses, regardless of material, to strict quality control checks. They test the glasses for leakage resistance, strength, and food safety compliance. After passing these checks, they package the glasses in bulk and ship them to distributors and retailers.

To explore more, check our books

Applications Across Industries

Events and Outdoor Consumption

From weddings and corporate events to concerts and festivals, disposable glasses are indispensable. They provide a quick, hygienic, and cost-effective solution for serving cold drinks to large crowds.

Retail and Household Use

Disposable cold drink glasses are also sold in supermarkets and local stores for household use. Families often purchase them for picnics, outings, or home gatherings where convenience matters.

Detailed project report

Competitive Advantages of Disposable Cold Drink Glasses

Hygiene and Safety

Unlike reusable glasses that require thorough cleaning, disposables ensure safety with every use. This aspect is especially important in public food service.

Customization and Branding

Disposable glasses double up as branding platforms, making them attractive for businesses seeking cost-effective advertising opportunities.

Cost-Effectiveness

Producing disposable glasses in bulk is relatively inexpensive, making them affordable for both businesses and consumers.

Challenges in the Industry

Raw Material Price Volatility

Fluctuations in the prices of plastic polymers and paper directly impact the manufacturing cost. This remains one of the key challenges for producers.

Competition and Market Saturation

The industry is highly competitive, with many small and medium-sized players operating in regional markets. Differentiation through quality, sustainability, and customization is necessary to remain competitive.

Market Forecast and Future Opportunities

Innovation in Materials

Future growth will rely heavily on the development of eco-friendly materials. Biodegradable polymers, recycled plastics, and plant-based coatings will gain momentum as regulatory pressures increase.

Expanding Export Potential

Exporters find significant opportunities in markets that import disposable glasses in large volumes. With the right certifications and compliance with international standards, manufacturers can tap into global demand.

Role of Niir Project Consultancy Services (NPCS)

Entrepreneurs exploring this business can benefit greatly from the expertise of Niir Project Consultancy Services (NPCS). NPCS prepares Market Survey cum Detailed Techno-Economic Feasibility Reports that include manufacturing processes, raw materials, plant layouts, and financials. These reports help entrepreneurs assess the feasibility of setting up new industries or businesses, making NPCS a valuable partner for informed decision-making.

Conclusion

The production of disposable cold drink glass manufacturing offers a dynamic and rewarding opportunity for entrepreneurs. With consistent demand from the food and beverage industry, rising awareness of hygiene, and the growing push for sustainable solutions, the sector is well-positioned for expansion. Startups entering this market can succeed by focusing on innovation, eco-friendly practices, and branding opportunities. By combining technical efficiency with consumer-centric strategies, entrepreneurs can build a successful venture in this thriving industry.

Discover the best business ideas for yourself using our startup selector tools.

Frequently Asked Questions

What types of materials are most commonly used for these glasses?

The most common materials are PET (polyethylene terephthalate), known for its clarity and strength; PP (polypropylene), which is more flexible; and PS (polystyrene), which is rigid and often used for brittle, clear cups.

What is the required machinery?

Essential machinery includes plastic extrusion machines to produce sheets of plastic and thermoforming or injection molding machines to shape the sheets into glasses. Printing and packaging machines are also needed.

What is the market demand for this product?

There is a consistent and high demand driven by the food and beverage industry, catering services, and various events. The market is also seeing a shift toward more eco-friendly and biodegradable options.

What are the main environmental concerns?

The primary concern is the plastic waste generated. Businesses are increasingly focused on using recyclable or biodegradable materials and implementing efficient waste management and recycling practices.

How can a business differentiate itself in this market?

Differentiation can be achieved through offering customization with branding and logos, focusing on sustainable and eco-friendly products, and ensuring competitive pricing and reliable supply chains.