Electric bikes (ebikes) lead the way in this green revolution, especially in densely populated areas where two-wheelers have been a mainstay for decades. Ventures into electric bike assembly are a great way for startups and MSMEs to take part in this green revolution, without having to invest heavily.

This guide will walk you through all the steps to launching a successful business assembling electric bikes, from understanding the market to exploring the actual assembly process.

Electric Bikes are a growing market.

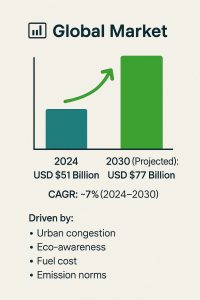

The electric bike market has been growing at a rapid pace globally. The electric bike market was worth USD 51 billion in 2024. This figure is expected to rise to USD 77 billion by 2030. This growth is due to a variety of factors, including a growing environmental consciousness, rising fuel prices, tighter emission regulations, and increased urban traffic congestion. These factors encourage individuals to look for eco-friendly, efficient alternatives to traditional modes of transportation.

In India, this shift is more pronounced. The electric two-wheeler market is gaining popularity with the government’s increasing support through policies such as the FAME II subvention, state-level incentives for EVs, and infrastructure support. In FY 2023-24, the number of electric bikes sold in India surpassed 9.4 lakh, a huge increase compared to prior years. India’s goal to achieve 100% adoption of electric two-wheelers by 2035 will increase demand for assembled ebikes.

It is the ideal time for entrepreneurs to enter this sector by using the relatively easy and cost-effective route of ebike assembly.

Related Article: Start a business in Electric Vehicle Industry

Understanding the Electric Bike Assembling Business Model

Assembling e-bikes does not require that you produce every component from scratch, unlike manufacturing. It involves assembling standard components, such as motors, batteries and frames, into a road-ready, functional product.

This approach has multiple benefits. This approach offers multiple advantages. Assembling allows you to concentrate more on branding, customization and the customer experience.

Many components can also be purchased from domestic and international vendors who are reliable, which allows for easy scaling and consistency in product quality.

Electric Bike Components

You must familiarize yourself first with the primary components of an e-bike in order to assemble one that is reliable and competitive. The frame is the backbone of any e-bike. It is usually made from aluminum alloy or stainless steel, and it supports the electrical and mechanical systems.

The motor is at the heart of any vehicle. It can be either a hub motor (installed in the wheel) or a mid-drive motor (located near the pedals). The motor is powered by a battery pack that’s usually lithium-ion. The battery specifications can vary, but are usually 36V or 48V with capacity tailored to speed and range requirements.

The controller, which manages the interaction of the battery with the motor, the throttle, the display unit, the brake system, the wheels, the suspension, the lights, and the pedal assistance system, is a critical component.

All these components are seamlessly integrated into a well-assembled electric bike, which ensures safety, comfort, and performance.

Watch Video:-

Explaining the Assembly Line Process

In order to set up an e-bike assembly operation that is successful, you need a production flow that is streamlined and efficient. The preparation of the frame is the first step. The frames are then checked for any defects and painted or powder-coated if necessary. Mounting points are also prepared to attach components.

Next comes motor installation. The hub motor can be mounted on a wheel with torque arms, depending on the design you choose. Mid-drive motors can be installed close to the pedal section and are connected to the drivetrain.

The battery integration process is the most delicate. Batteries can be attached to either the down tube of the frame or the rear rack and are wired securely to the controller. The electrical wiring is then connected to the throttle, display, and lights.

After the electronic components are installed, the wheels, brakes, and suspension systems are added. The unit is tested for quality after final assembly. This includes checking the motor’s performance, battery output, brake function, and overall ride quality.

The e-bike is only packed and ready for delivery after it has passed all the tests. The process can be carried out manually for smaller units or on conveyor lines for larger operations.

Set up your plant: Layout and Flow

To maintain quality and productivity, a well-organized layout will be critical. The typical e-bike production plant is divided into zones for receiving components, inspection, subassembly, final assembly (such as battery and motor integration), quality testing, and storage of finished products.

Lean manufacturing principles, ergonomic workstations and ergonomic designs can improve the efficiency of material handling and assembly. For smaller setups, basic workbenches with hand tools may be sufficient. Medium-sized operations can benefit from semiautomated conveyors and specialized assembly fixtures.

It is important to consider safety protocols, ventilation in the battery testing area (especially), and expansion capacity as demand increases.

Read Book on:- Electric Vehicles Manufacturing

Supplier Selection and Supply Chain Strategy

The right supplier is crucial to the success of your business. India is home to a growing number of EV component makers, but you may have to import specific components like batteries or controllers from China, South Korea or Taiwan.

It is important to establish strong relationships with several vendors in order to ensure consistency and reduce the risk of delays or disruptions. Standardizing components is also a good idea to reduce costs and streamline procurement.

When selecting vendors, it is important to consider the quality certifications of ISO, BIS and CE. This will help maintain safety and compliance standards.

The Business of the Future: Emerging Trends

The e-bike industry is undergoing a number of developments that are pushing the limits of what’s feasible. This gives newcomers plenty of room to innovate and stand out.

Government incentives are a driving force that reduces the cost burden on both manufacturers and buyers. Initiatives such as battery swapping stations and increased charging infrastructure address one of the biggest challenges: range anxiety.

Smart e-bikes are in high demand from consumers. They are equipped with IoT features such as real-time GPS tracking and anti-theft alarms. Ride analytics and smartphone integration is also available. Bulk orders and B2B assembly contracts are further widened by the rise of shared mobility startups and e-bike rental platforms.

The low operating cost and easy maintenance of e-bikes have led to a growing demand in semi-urban and rural areas.

View Project Report on:- Electric Vehicles

Export Potentials and Global Market Reach

E-bike assembly is not limited to the domestic markets. Africa, Southeast Asia and parts of Europe have shown an increased interest in low-maintenance, affordable electric two-wheelers.

India’s low-cost engineering ecosystem allows local entrepreneurs to create products of export quality at competitive prices. To expand internationally, however, it is necessary to adhere to certain standards, such as UN ECE certification or CE marking in Europe.

Exporting can also help you scale up your business quickly with higher profit margins.

Startups: Ideal business models

This industry can be approached in many different ways. Entrepreneurs may decide to create their own branded electric bikes, aiming at niche markets like college students, delivery people, or seniors. Some may choose to white-label the assembling of larger brands or fleets.

Other viable options include franchise-based models, D2C online sales, and B2B partnerships through rental platforms. Customizing products to different demographics is easy when you are at the assembly stage.

To secure repeat orders, many founders explore partnerships with startups in logistics or government mobility schemes.

Find Best Business Ideas for Yourself using our Startup Selector Tool

How NPCS Can Help You Start and Grow a Successful Business

Niir Project Consultancy Services (NPCS) is a trusted partner for entrepreneurs, startups, and small business owners across India. With decades of experience, NPCS provides in-depth support to turn innovative ideas into scalable businesses — especially in emerging sectors like agro-waste-based manufacturing, specialty chemicals, home-based businesses, and more.

Market Research & Techno-Economic Feasibility Report

Market Research & Techno-Economic Feasibility Report

NPCS delivers comprehensive market research reports that include:

Industry trends and demand analysis

Legal and regulatory requirements

Raw material sourcing and local supply chain insights

Cost structure and value chain assessment

These reports help you validate your business idea and understand its viability in the real market.

Frequently Asked Questions:

- How Do I Start an Electric Bike Business from Scratch?

- Starting an electric bike business involves several steps, including market research, business planning, sourcing suppliers, legal requirements, and marketing. You’ll need to determine your niche, budget, and target audience to get started.

- What are the Key Legal and Regulatory Considerations for Selling Electric Bikes?

- Legal and regulatory requirements may vary by location, but typically you’ll need to register your business, obtain necessary permits and licenses, adhere to safety standards, and understand tax obligations. Compliance with local and national electric bike regulations is crucial.

- How Do I Choose the Right Electric Bike Suppliers and Manufacturers?

- Finding reliable suppliers and manufacturers is essential. Look for companies with a good track record, quality products, competitive pricing, and the ability to meet your demand. Conduct due diligence, ask for samples, and build strong supplier relationships.

- What Marketing Strategies Work Best for Promoting Electric Bikes?

- Effective marketing strategies include creating a professional website, utilizing social media, engaging in content marketing, and participating in industry events. Additionally, partnering with local bike shops or offering test rides can help build brand recognition.

- How Can I Differentiate My Electric Bike Business in a Competitive Market?

- To stand out, consider offering unique features or designs, focusing on eco-friendly and sustainable aspects, providing exceptional customer service, and building a strong brand identity. You can also explore niche markets, such as cargo bikes or electric mountain bikes, to differentiate yourself.

Market Research & Techno-Economic Feasibility Report

Market Research & Techno-Economic Feasibility Report

Im sujeet Kumar

Respect sir ,

I want to ev agency’s, u guide me.

Also part of ev for assembl by me