Edible oils are constantly scrutinized in today’s health-conscious marketplace. The consumer is not only concerned with flavor and price but also nutrition, purity and authenticity. Groundnut Oil Manufacturing is a popular, natural, and trusted option among the Indian edible oils. Groundnut oil production has become a highly profitable business due to the growing demand for unrefined, chemical-free cooking oils.

You should seriously consider groundnut oil production if you are an aspiring industrialist or entrepreneur looking for a manufacturing concept that can combine strong consumer demand, long-term profitability, and export potential. Is it right for you? Let’s look at the opportunity in detail.

Why groundnut oil remains one of India’s most valuable edible oils

Groundnut oil is extracted from groundnut seeds or kernels. Rich in monounsaturated fats, Vitamin E, and plant-based protein, groundnut oil has been a staple in Indian kitchens for generations–especially in states like Gujarat, Tamil Nadu, and Andhra Pradesh.

Unlike refined oils that undergo chemical treatments, groundnut oil–especially when cold-pressed–retains much of its natural flavor, aroma, and nutritional properties. It is a favourite not only with home cooks, but also with restaurants, food processing plants, and exporters. Its high smoking point makes it perfect for frying. And its long shelf-life offers additional advantages both in domestic and industrial applications.

Today, with health trends swinging away from chemically processed and blended oils, groundnut oil is seeing a resurgence–particularly in urban centers where educated consumers are actively seeking pure, unrefined alternatives.

Related: Business Ideas for Groundnut Oil Production and Refining

Market Outlook for Groundnut Oil in India and Worldwide

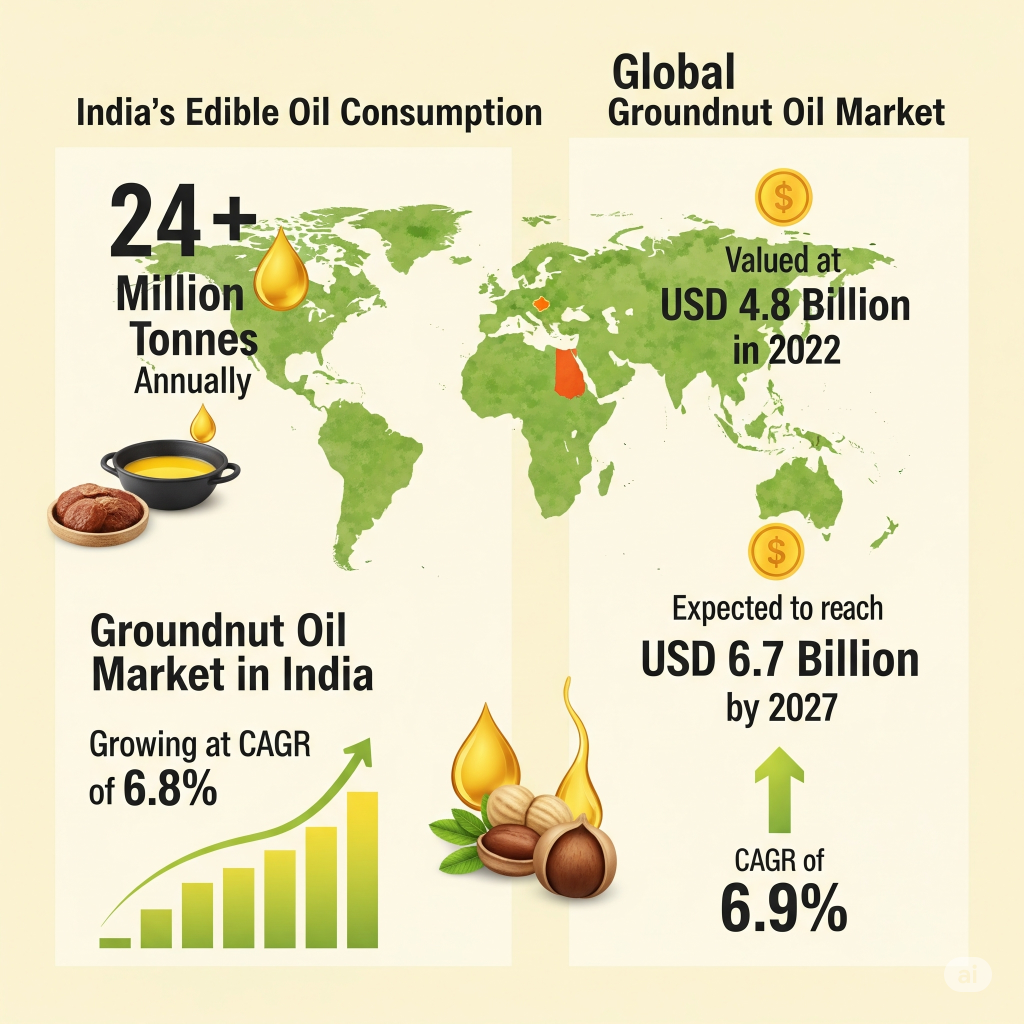

India’s market for edible oil is huge, with over 24 million tonnes consumed annually. Groundnut oil is a small but rapidly growing segment within this market, largely due to its perceived benefits. Industry reports indicate that the Indian groundnut oil market grows at a CAGR of 6.8%. This is due to increasing health awareness, demand for premium products, and growth of organic food retail.

The groundnut oil industry is also exhibiting impressive trends on a global level. Global groundnut oil was valued at USD 4.8 billion in 2022, and it is expected to reach USD 6.7 billion by 2027 with an average CAGR 6.9%. This demand is largely driven by Asian markets such as India, China, and Southeast Asian countries. There is a growing demand for cold-pressed oil and organic food in markets such as the United States and the Middle East.

Exporters in India are leveraging this potential by providing groundnut oil in bulk and in branded packaging that meets international standards. Agri Export Zones and schemes run by the Ministry of Food Processing Industries help groundnut oil producers access new markets through better logistics and financial incentives.

Business Potential: Why is groundnut oil manufacturing a lucrative choice?

Groundnut oil is a low-volatility raw material that offers a wide range of products and customers. Here are some key business advantages:

- India has a plentiful supply of raw materials. States like Gujarat, Rajasthan and Maharashtra ensure a year-round raw material supply.

- Dual revenue model: The manufacturing processes yield not only oil but also groundnut cake, which is used in animal feed, organic fertiliser, and other agro industries.

- Branding and niche market potential: Cold-pressed and filtered oil from groundnuts can be positioned for urban and health-conscious buyers.

- Export flexibility: Units can explore export options for refined oil and cold-pressed varieties with the proper certifications.

A small or medium-sized unit of oil extraction can serve local retailers, bulk food suppliers, and D2C platforms. Brand potential in niche markets for health and wellness further increases its profitability.

Related: How to Start a Profitable Groundnut Processing Business

Groundnut Oil Production Process: A Technical Walkthrough

The success of any groundnut oil production unit is heavily dependent on the quality, hygiene and efficiency of each stage. The basic flow is the same whether you are setting up a cold-press facility or a large expeller-based plant. Here’s a summary of the main steps:

1. How to source and pre-clean raw groundnuts

To begin, you must first source mature, high-quality groundnut pods. The moisture content of the raw material is crucial to oil yield. Therefore, it must be dried under sunlight or with mechanical dryers before processing. The pre-cleaning process removes impurities such as dust, stones, plant debris and other contaminants using gravity separators or destoners.

2. De-shelling & Kernel Cleaning

After cleaning, the groundnuts go through a shelling machine to separate the outer shell and the kernel. The husks are then separated from the seeds using air blowers and gravity tables. It is important to have clean, dried, and sorted seeds for maximum oil yield and flavor.

3. Roasting (Optional, depending on the product line)

Manufacturers may choose to lightly toast the kernels prior to extraction in order to enhance the flavor of the oil and extend its shelf life. This is more common with artisanal and cold-pressed oils, where aroma and taste are important selling points. The roasting process also reduces anti-nutritional elements and increases oil extraction efficiency on certain machines.

4. Oil Extraction Methods: Cold Pressing and Expeller

Oil extraction can be divided into two major categories:

- Cold Pressing – In this method the groundnut kernels (usually less than 45 degC) are pressed using rotary presses made of wood or steel at low temperatures. Heat or chemicals are not used. This produces a higher-quality, but lower-quantity oil that is richer in nutrients and flavor.

- Pressing with an expeller: This method uses screw press to crush and extract the oil under moderate heat and high pressure. This method yields more oil for each kilogram of seeds, which makes it ideal for commercial or large-scale operations.

Filtering the oil using cloth filters or pressure filter is done to remove any suspended particles. Raw groundnut oil is the result. It can be sold either as-is, filtered oil or further refined based on the market.

5. Byproduct Utilization: Groundnut Cake

The residual pressed material, also known as oil cake or groundnut cake, is a valuable byproduct. It is a valuable byproduct because it contains a lot of protein and fiber. It can be used as an organic fertilizer or in animal feed. Oil cake can be packaged, dried, and pelletized to create additional revenue.

6. Packaging and Quality Control

To ensure compliance with food safety regulations, the final oil is tested for its acidity, moisture content and aflatoxin levels. After packaging, the oil is packaged into consumer-friendly bottles or pouches. Bulk buyers might require HDPE drums or tins of 15-20 liters. Packaging must adhere to FSSAI labeling standards and include information such as batch number, shelf-life, and nutrition.

Legal, Regulatory and Infrastructure Requirements

The Groundnut Oil Manufacturing unit must meet certain infrastructure and legal requirements before it can begin operations. A FSSAI licence is required for all food products, including edible oil. Registering the business as Udyam allows entrepreneurs to benefit from tax advantages, subsidies and easier credit. If you’re selling oil for human consumption, you will also need a Factory License and a Pollution Control NOC. Import Export Codes (IECs) are required if you’re targeting international markets.

Infrastructure-wise, it is important that the unit be situated in a zone of industrial or agroprocessing with clean water, uninterrupted power, and good road access. A food-safe floor, stainless steel tanks and waste oil management systems are also required for an oil processing line.

Check out our Handbooks here

Selling Groundnut oil: Customers, Channels and Branding Potential

The type of product that you produce will determine your target market. Wholesale buyers, such as local grocers and food processors, are the best for filtered groundnut oils. The branding potential of D2C is huge if you are producing cold-pressed oils. Customers are buying artisanal oil via ecommerce platforms, farmers’ markets, and organic stores.

You can approach distributors, institutional buyers (hotels and caterers), government programs for food, and retail outlets to make large, consistent sales. You can also sell your oil to exporters or merchant traders for shipment into African, Middle Eastern, and Southeast Asian markets.

Branding, especially packaging, hygiene, and labeling, plays a major role in all cases. Labels that state “filtered oil”, “chemical-free”, and “chemical-free” are increasingly sought after by consumers. Brand value can be significantly increased by telling the story of purity.

Groundnut Oil and Other Edible Oils: Strategic comparison

Groundnut oil is more expensive than other oils like soybean or palm. It is a popular choice for “health-conscious consumers” and premium retailers. Other oils are dominant in large FMCG categories, institutional catering and other categories. This allows startups to charge higher prices and build brand loyalty, especially among consumers who are looking for natural alternatives to refined and factory-blended oil.

The oil is also rich in healthy fats and resistant to oxidation. It’s cholesterol-free. The high smoke point of groundnut oil makes it perfect for Indian cooking. Olive oil, on the other hand, breaks down when heated to high temperatures. These features give it a unique place in the Indian edible oils landscape.

For more information check out this video

Are you the right person to run this business?

Groundnut oil production is a great business to consider if you want a steady income, an agro-based distribution chain, brand potential and exportability. This business requires:

- Focus on raw materials and quality assurance.

- Attention to hygiene, compliance and food safety.

- Packaging and marketing that is smart to help you position your oil.

- Willingness of the company to invest in equipment, training and branding.

Entrepreneurs who have access to areas where groundnuts are grown or can establish farmer links will benefit. Also, startups that focus on natural foods and D2C health are a good fit.

How NPCS helps entrepreneurs succeed in groundnut oil manufacturing

Niir Project Consultancy Services provides entrepreneurs with detailed techno-economic feasibility reports tailored to the groundnut sector. These reports include the entire manufacturing process. They also list raw materials requirements, outline layouts of plants, and provide financial projections as well as risk assessments. NPCS helps new businesses understand the market, regulatory requirements, and technical options prior to investing. They have decades of experience working in the industrial and agroprocessing sectors. This helps you to launch your business more confidently.

Find Best Idea for Yourself With our Startup Selector Tool

Final Thoughts

The groundnut oil industry is a business that’s more than traditional. It’s an opportunity for the modern age. It’s a great time to invest in the premium edible oil market, with its growing global demand, increasing health awareness, and rising demand for natural food. This industry is a good investment if you are passionate about delivering a high-quality oil and have a strategy for building a brand around tradition and purity.

Is groundnut oil production the right business for me?

Yes, it is if you are interested in tapping into India’s agricultural strength and transforming it into trusted food products, as well as building a scalable industry venture.