India is making a rapid transition to greener and sustainable fuels. Ethanol is at the core of this change. Ethanol Production Business, as a biobased and renewable fuel, is not only an environmentally friendly alternative but also a lucrative opportunity for entrepreneurs looking to take advantage of the next wave in energy innovation. Setting up an ethanol business is a good option if you are looking for manufacturing opportunities that have long-term demand as well as policy support.

This guide was designed for business consultants and startup founders who are evaluating green energy opportunities. This guide will take you through the ethanol industry landscape, manufacturing process, applications of the product, and future outlook without diving into financial or investment details.

Understanding Ethanol’s Industrial Relevance

Ethanol is also known as ethyl liquor, and it’s a biofuel that’s commonly made from agricultural feedstocks like sugarcane. maize, rice, molasses, or rice husk. The importance of ethanol goes beyond fuel blends. It is also vital to the chemical, pharmaceutical, and beverage industries. In India, the government is pushing for energy security and climate-resilient industrial development.

The Ethanol Production Business sits at the intersection of agriculture, energy, and industrial manufacturing–making it a high-impact sector with opportunities for circular economy practices, rural employment, and carbon reduction.

Related: How to Start Ethanol Production from Sugarcane Business in India

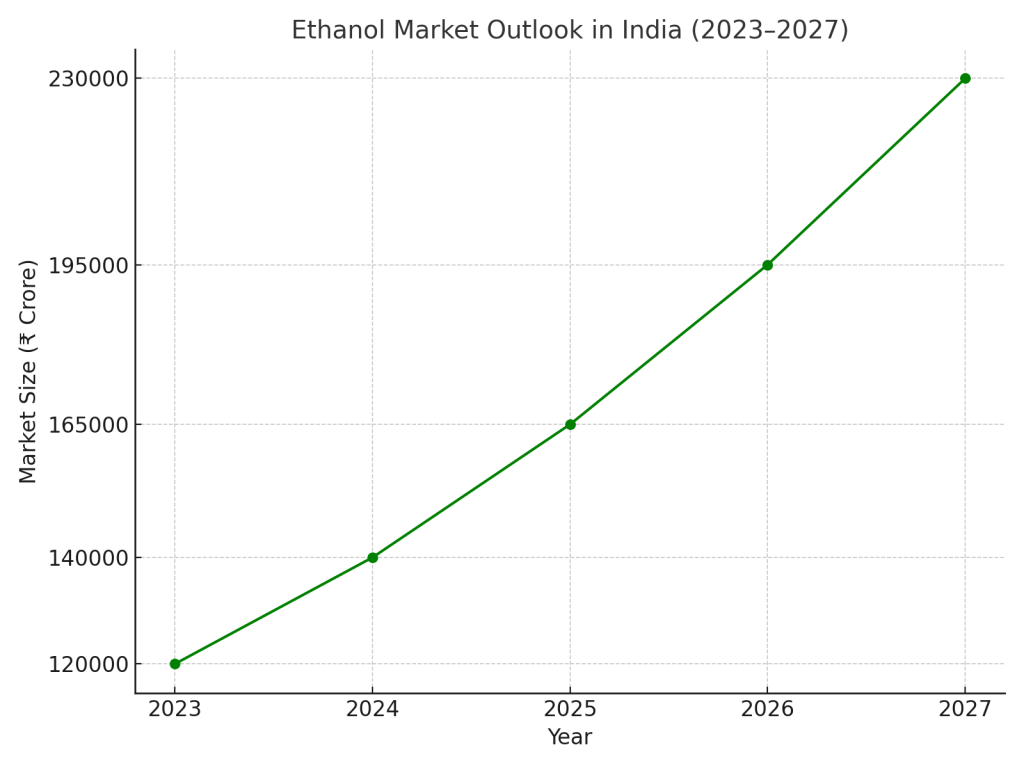

Market Outlook for Ethanol Demand in India

Ethanol Blending & the National Policy Push

The government of India has set aggressive targets for its Ethanol Blended Petrol Programme (EBP), which aims to reduce India’s dependence on crude oil imports. The government has set aggressive targets for the EBP Programme, which aims to reduce India’s dependence on imported crude oil.

This is more than a mandate from the government. It’s a great business opportunity. To meet the 20% blend requirement, the annual ethanol production must exceed 1,000 crore litres. This will require constant industrial expansion and innovative production methods.

Market Size and Forecast (2020-2030).

| Year | Estimated Ethanol Market Volume (Litres). | Blending Target (%) | Demand Driver |

| 2025 | 1,100 crore litres | 20% | Transport Fuel |

| 2026 | 1,250 crore litres | 20%+ | Fuel, Aviation, Pharma |

| 2027 | 1,400 crore litres | Increased industrial use | |

| 2028 | 1,600 crore litres | Export Growth | |

| 2029 | 1,800 crore litres | Cosmetics containing bio-Chemicals | |

| 2030 | 2,000 crore litres | Renewable Energy Integration |

This is due both to government purchases and private sector demands for fuel, food and cosmetics.

The Key Drivers of Starting an Ethanol Production Business

Policy and Subsidies: Government incentives for feedstock supply, interest subvention on loans, and assured procurement through Oil Marketing Companies (OMCs) make ethanol manufacturing an entrepreneur-friendly sector.

India’s agricultural landscape offers multiple feedstock options, including 1G (first generation) and 2G (2nd generation) feedstocks. This allows for flexibility and resilience in the supply chain.

Ethanol has a wide range of applications.

- Fuel blending for automobiles

- Production of disinfectants and sanitizers

- Solvents used in the pharmaceutical industry

- Alcoholic beverages

- Industrial chemicals

Circular Economy Models – Ethanol production is aligned with zero waste principles. Distillery waste, such as spent wash (spent wash), can be used to generate electricity or biogas.

Manufacturing Process of Ethanol

The process may vary slightly depending on the feedstock – molasses or grains, or even lignocellulosic biomass – but the basic steps are the same.

1. Feedstock preparation

The raw materials (e.g., molasses, grains, etc.) are cleaned and crushed (if necessary), then diluted until the sugar concentration is achieved. Starch liquefaction, saccharification and starch conversion are also used in grain-based plants to convert starch to fermentable sugars.

2. Fermentation

The mash prepared is then transferred into fermenters where yeast (Saccharomyces Cervisiae), is added. This microorganism transforms sugars into carbon dioxide and ethanol. Fermentation lasts 48-72 hours.

3. Distillation

The distillation process separates ethanol from the fermented mixture using multi-stage distillation columns to achieve different ethanol purity levels.

- Rectified spirit (95%).

- Absolute ethanol (99.9%) for blending

- Extra Neutral Alcohol for Pharmaceuticals and Beverages

4. Dehydration

Molecular sieves or azeotropic distillation remove water from fuel-grade (anhydrous) ethanol to ensure it can be blended with petrol.

5. By-Product Recovery

Distillers often incorporate systems to capture:

- Carbon dioxide (CO2) is produced during fermentation and used in carbonated beverages.

- Distillery waste wash for biogas and organic fertilizer

- DDGS (Distillers’ Dry Grains with Solubles), as a high-protein animal food

Related: ETHANOL BLENDING IN INDIA – Opportunities For Startup

What are the different types of feedstock used for ethanol manufacturing?

India’s biofuel policy allows for ethanol production in various categories.

Category A: High-yield feedstocks: sugarcane juice and sugar syrup

Category B: Heavy molasses (B-Heavy) – sugar extracted and removed

Category C: Traditional Molasses, lower yielding but available all year round

Cat D: damaged food grains, broken rice, excess rice from FCI

Category E (2G bioethanol): Agricultural residues – cotton stalks, rice straw, bagasse

The choice depends on the availability in your region, cost dynamics and end-uses (fuel, pharma, or beverage).

Regulatory Environment and Licensing

Start-up ethanol businesses require regulatory approvals by central and state authorities.

- Environmental clearance, especially for large-scale distilleries

- Pollution Control Certification

- Excise license for ethanol used to make ENA or beverage liquor

- Food Safety (FSSAI), for food-grade ethanol

- Biofuel Policy Alignment – Registration with Oil Marketing Companies for Ethanol Procurement

The Department of Food and Public Distribution also manages the tender and ethanol purchase process.

Plant Location and Logistics Considerations

Find an ethanol plant nearby:

- Sugar mills for molasses

- Grain mandis (for broken maize or rice) or FCI depots

- Hubs for rail or road transport

can reduce transportation costs significantly and improve the efficiency of your plant. Factors such as availability of water and energy, proximity to mixing depots, and effluent infrastructure also influence site selection.

Innovation and Technology Adoption: Scope

In order to improve efficiency and reduce waste, the ethanol industry increasingly integrates automation and digital controls. Innovations include:

- Zero Liquid Discharge (ZLD) systems

- Bio-CNG production from distillery waste

- Grain to gas technologies

- Platforms for 2G bioethanol using enzymes and pretreatment systems

These innovations not only increase profitability but also make operations more compliant.

Challenges to consider

Entrepreneurs must understand that ethanol production is a lucrative opportunity. However, there are challenges specific to the sector.

- Seasonal variations in feedstock availability and prices

- Complicated regulatory and excise compliance

- Requirements for wastewater treatment and air emissions control

- Balance the product mix between ENA and fuel ethanol

Proper planning and technical assistance can minimize these risks and help build a compliant, scalable business model.

Ethanol export potential: A future avenue

As the global economy shifts to green fuels, ethanol has become a commodity that is traded. India could become a regional hub for ethanol, supplying Southeast Asia, Africa, and Gulf countries. Export-oriented entrepreneurs can explore partnerships abroad with distilleries, bottling plants, and beverage-grade ethanol.

For more information, check this video

How NPCS supports entrepreneurs in starting ethanol projects

Niir Project Consultancy Services is a specialist in preparing Market Surveys and Detailed Techno-Economic Feasibility reports that assist entrepreneurs to assess the viability ethanol or other industrial ventures.

The detailed reports include:

- Flow diagrams of the complete manufacturing process

- List of raw material suppliers, machinery suppliers, and utilities

- Plant layout design and capacity planning

- Market analysis and financial forecasts

Whether you are a first-time entrepreneur or a consultant advising an industrial client, NPCS Reports offer the technical and strategic foundation to launch a successful ethanol business.

Which business to start? How to choose a business idea?

Final Thoughts

It’s not just about government-backed fuel blends. Ethanol is a business model that has deep roots in sustainability and the circular economy. It opens up a market that is future-oriented and policy-driven, with multiple revenue streams in the fuel, pharmaceutical, and agroindustrial sectors.

Setting up an ethanol production unit is one of the most profitable industrial ventures in this decade. It requires a structured plan, process expertise and the right feasibility insights.